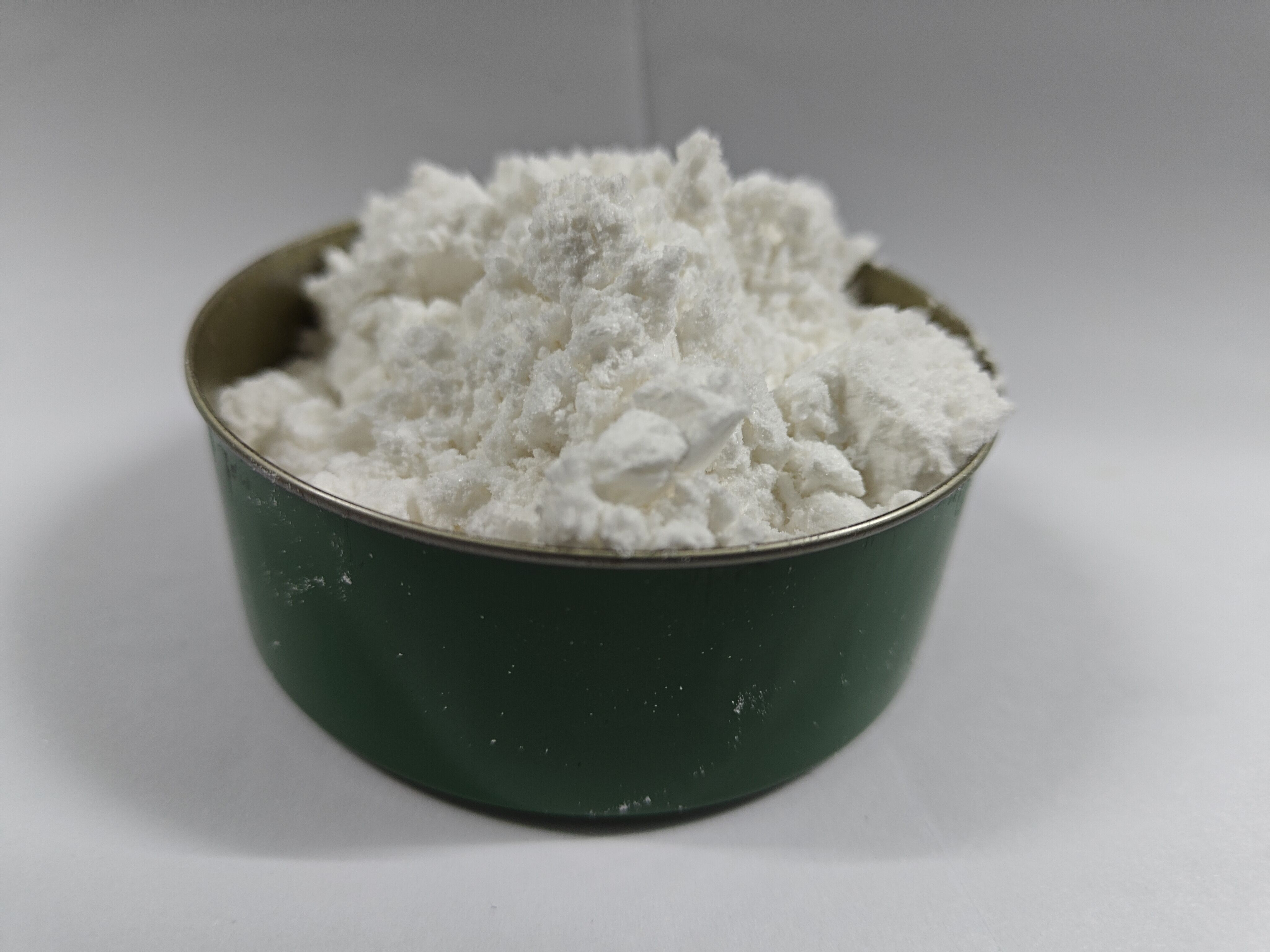

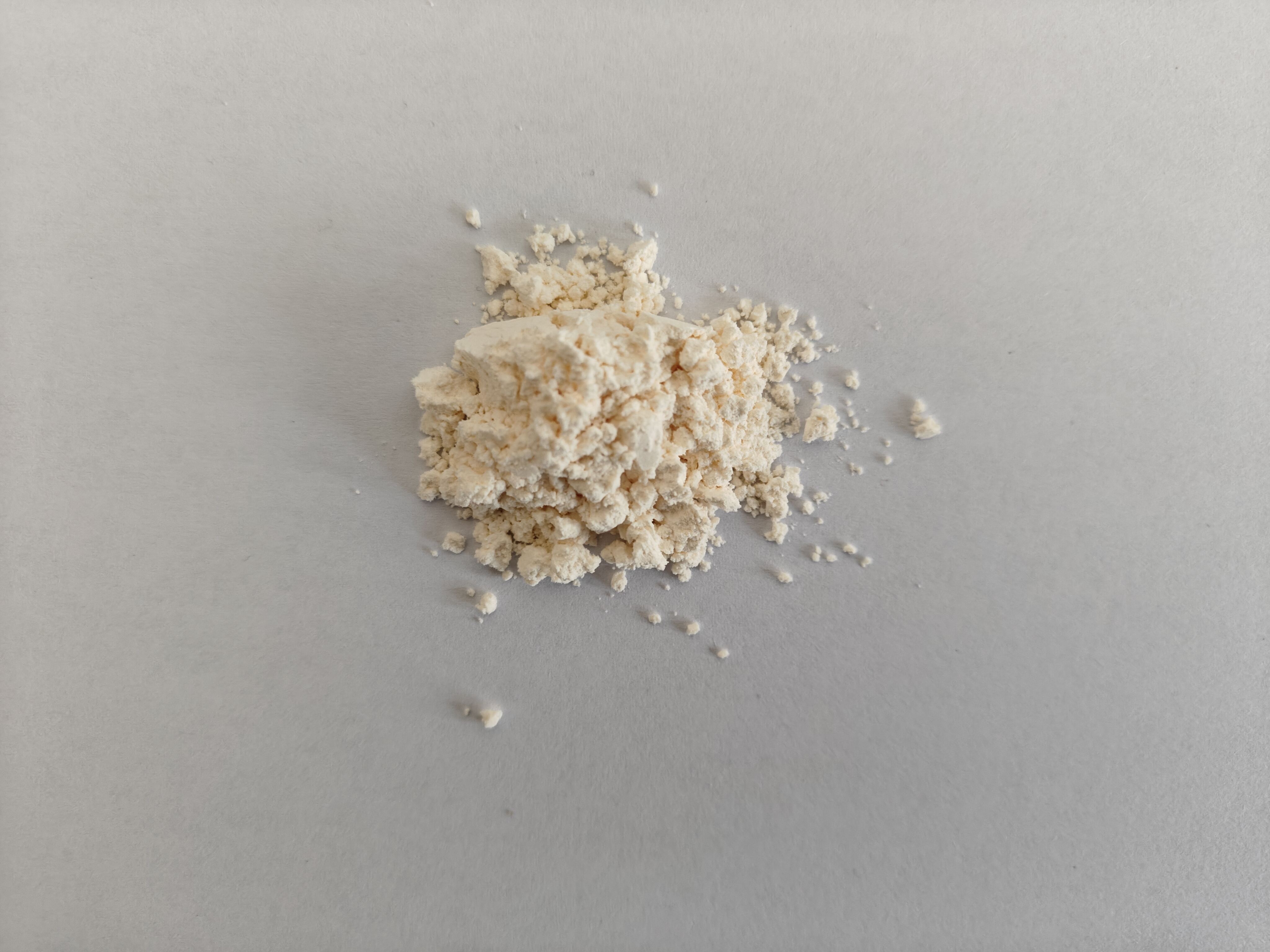

epoxy resin molding compound

Ang epoxy resin molding compound (EMC) ay isang mataas na katutubong thermoset material na madalas gamitin sa semiconductor packaging at elektронikong komponente ng encapsulation. Ang maanghang na kumpound na ito ay nag-uugnay ng epoxy resin kasama ang iba't ibang filler, hardener, at modifier upang gawing matatag na proteksyon material. Nag-aalok ang EMC ng kamahalan na lakas mekanikal, masusing resistensya sa ulan, at kamahalan na thermal stability, ginagawa itong ideal para protektahan ang sensitibong elektronikong komponente. Dumadaan ang kumpound sa isang kimikal na pagpapakilala kapag nakikita ang init at presyon, bumubuo ng isang maligong, mabagsik na estraktura na epektibong nagbibigkis sa mga elektronikong device mula sa mga environmental factors. Ang kanyang mababang coefficient ng thermal expansion ay nagpapatakbo ng dimensional stability sa pamamagitan ng iba't ibang temperatura ng operasyon, habang ang kanyang kamahalang adhesion properties ay nagpapatuloy na magbigay ng reliable bonding sa iba't ibang substrate materials. Ang versatility ng EMC ay umuunlad patungo sa kanyang processing capabilities, nagpapahintulot sa parehong transfer molding at compression molding techniques. Ang balanse na characteristics ng pamumuhunan ng material ay nagpapahintulot ng punong pagsulong ng mga komplikadong mold cavities, nagpapatuloy na makapag-encapsulate ng mga komponente nang walang butas o defektos. Pati na rin, nag-aalok ang EMC ng kamahalan na electrical insulation properties, kritikal para maintindihan ang integridad at pagganap ng mga elektronikong device.