mga manggagawa ng epoxy molding compound

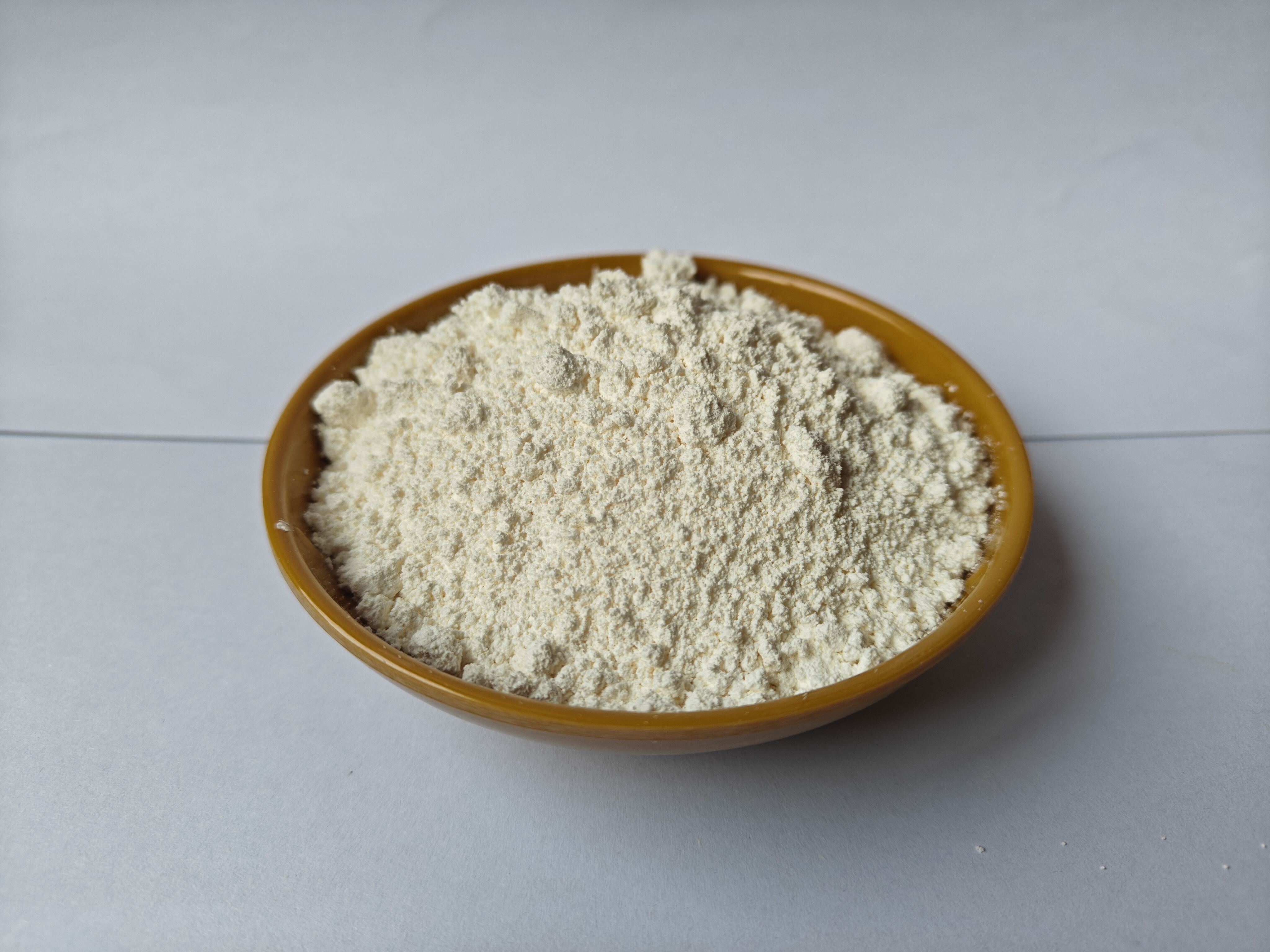

Mga gumagawa ng epoxy molding compound ay mahalagang mga player sa industriya ng semiconductor at elektronikong komponente, na nakikispecial sa paggawa ng mataas na katutubong materiales para sa encapsulation. Nagdedevelop at nagpaproduce ang mga ito ng espesyal na mga compound na protektahan ang sensitibong elektronikong komponente mula sa mga pang-ambiente na factor, mekanikal na stress, at termal na hamon. Ang kanilang produkto ay nagkakasunod-sunod ng epoxy resins, hardeners, at iba't ibang fillers upang lumikha ng mga compound na may espesyal na katangian tulad ng maayos na pagdikit, mababang pagpapalawig ng init, at masusing resistensya sa ulan. Ginagamit ng mga modernong facilidad para sa paggawa ng advanced na mga teknika sa produksyon, kabilang ang mga sistema ng presisyon na paghalo at matalinghagang mga sukat ng kontrol sa kalidad, upang siguruhin ang konsistente na kalidad ng produkto. Ang mga compound na ipinaproduce nila ay mahalaga para sa mga aplikasyon sa automotive electronics, consumer devices, industrial equipment, at aerospace components. Nag-iinvestadong malaki ang mga ito sa pananaliksik at pag-unlad upang lumikha ng makabagong solusyon na tugunan ang bumubuo ng demand sa industriya, tulad ng mga compound nakopatible para sa 5G technology at electric vehicle applications. Paminsan-minsan din silang nagfokus sa pag-unlad ng mga formula na kaugnay sa kapaligiran na sumusunod sa pribilehiyo ng pandaigdigang regulasyon habang pinapanatili ang mataas na pamantayan ng pagganap. Kinakailangan ng proseso ng paggawa ang mga sophisticated na kagamitan para sa pagproseso ng material, pagsusuri, at quality assurance, upang siguruhin na bawat batch ay sumusunod sa matalinghagang mga especificasyon ng industriya.