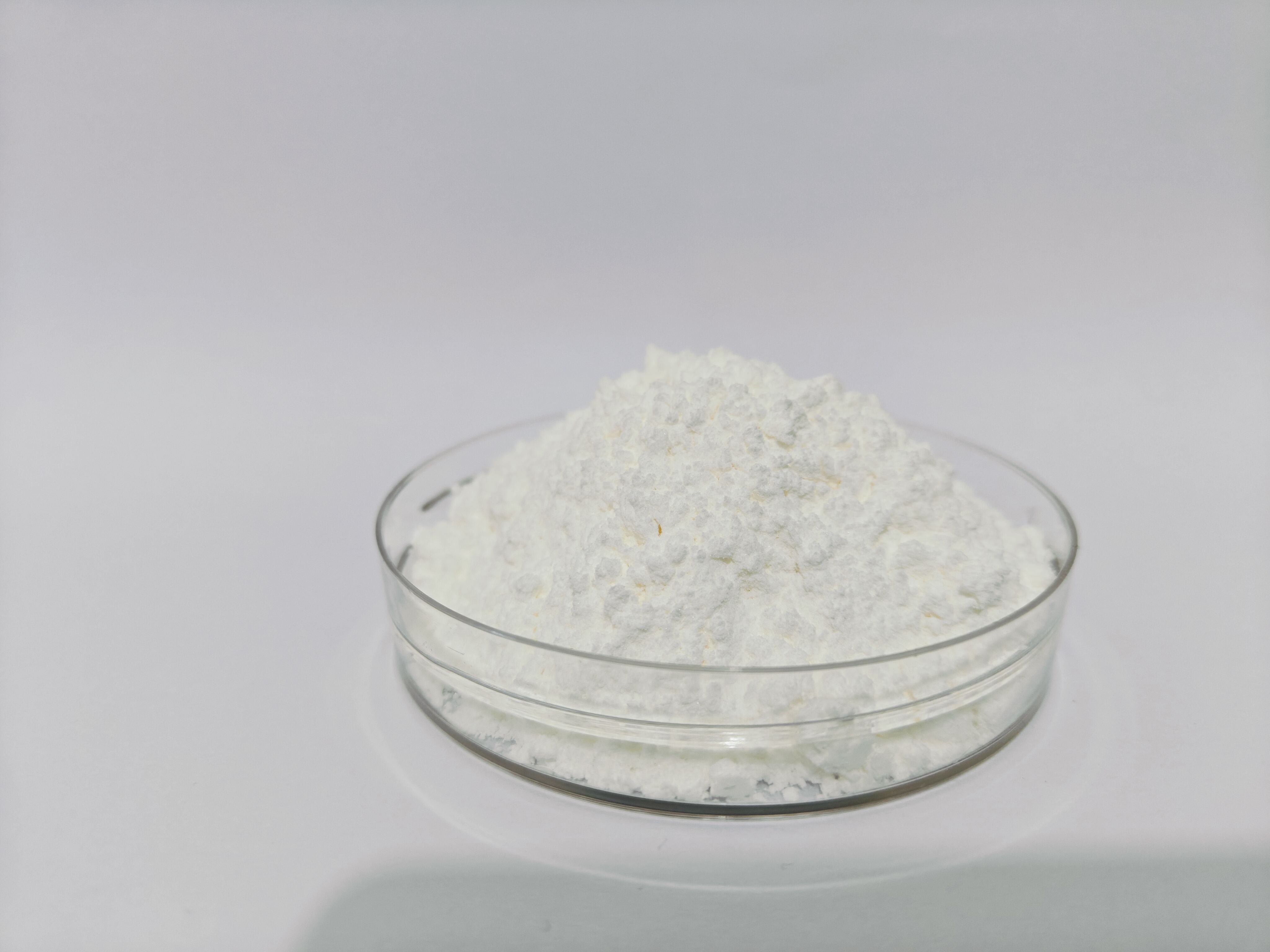

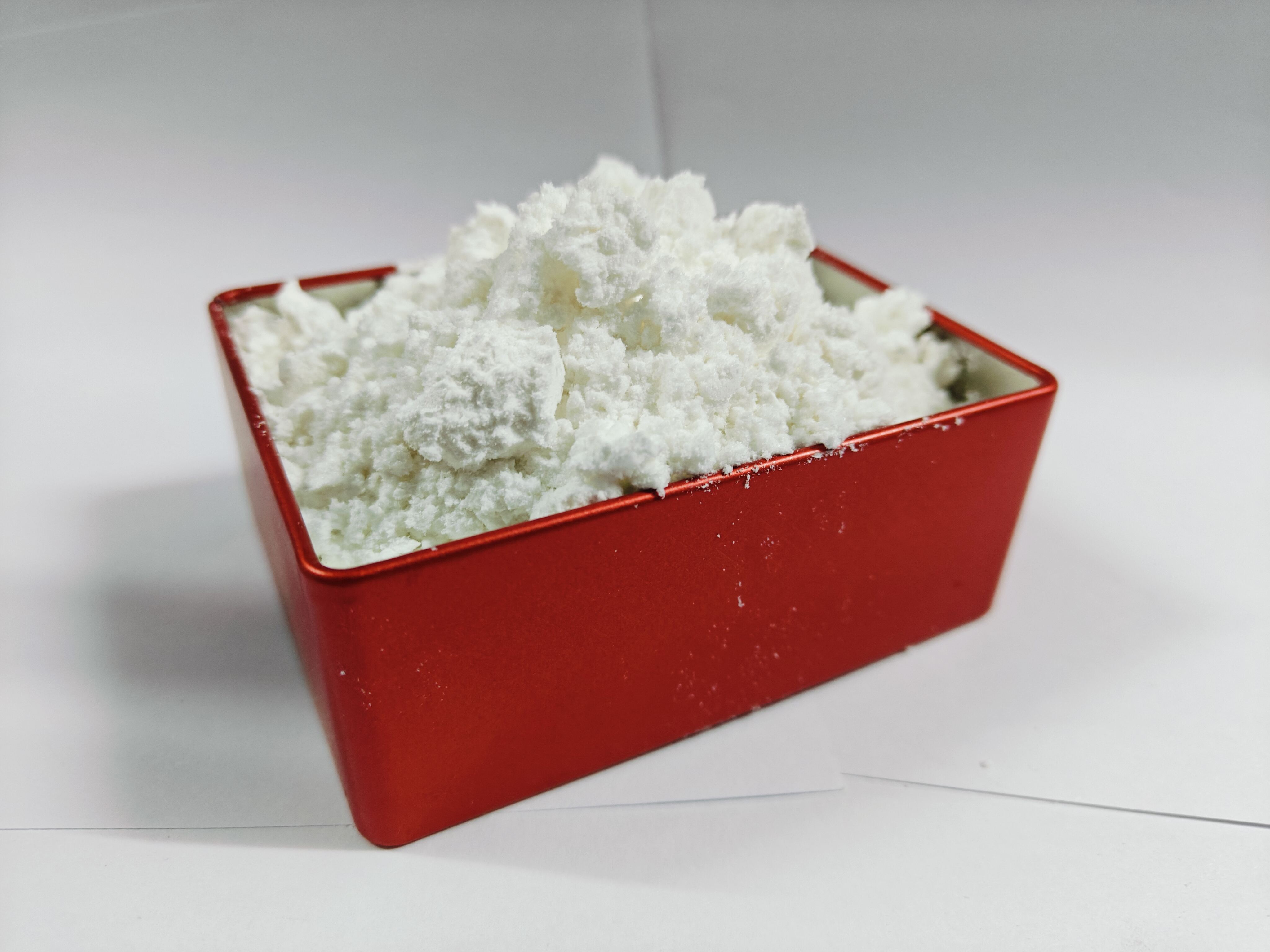

hoog kwaliteit epoxy vormmiddel

Hoë kwaliteit epoksi gietverbinding (EMC) verteenwoordig 'n voorpunt-kapselmateriaal wat spesifiek ontwerp is vir halfgeleierverpakkingstoepassings. Hierdie gevorderde verbinding kombineer uitstekende meganiese sterkte, uitstekende termiese eienskappe en uitsonderlike vogbestandheid om elektroniese komponente omvattend te beskerm. Die materiaal bestaan uit epoksi hars as die basispolimer, gekombineer met verharders, vlamvertragers en gespesialiseerde vulstowwe wat die prestasie-eienskappe daarvan verbeter. EMC's is ontwerp om betroubare beskerming teen omgewingsfaktore, meganiese spanning en termiese siklusse te bied terwyl hulle uitstekende hechting aan verskillende substraatmateriale handhaaf. Die verbinding se formulering maak dit moontlik om die vloeiproeienskappe tydens die gietproses presies te beheer, wat volledige holte vul en leemtevrye inkapseling verseker. Die lae termiese uitbreidingskoëffisiënt help om spanning op interne komponente tydens temperatuurskommelings te voorkom, terwyl die hoë glas oorgangstemperatuur stabiliteit oor 'n wye bedryfsbereik verseker. Moderne EMC's het ook verbeterde vogbestandheidseienskappe wat delaminering voorkom en sensitiewe elektroniese komponente teen vogverwante mislukkings beskerm. Hierdie verbindings word wyd gebruik in geïntegreerde stroombane, diskrete halfgeleiers en verskeie elektroniese modules, wat 'n koste-effektiewe en betroubare oplossing bied vir elektroniese verpakking behoeftes.