Comment les liaisons amides CDI améliorent-elles l'efficacité des réactions en chimie organique ?

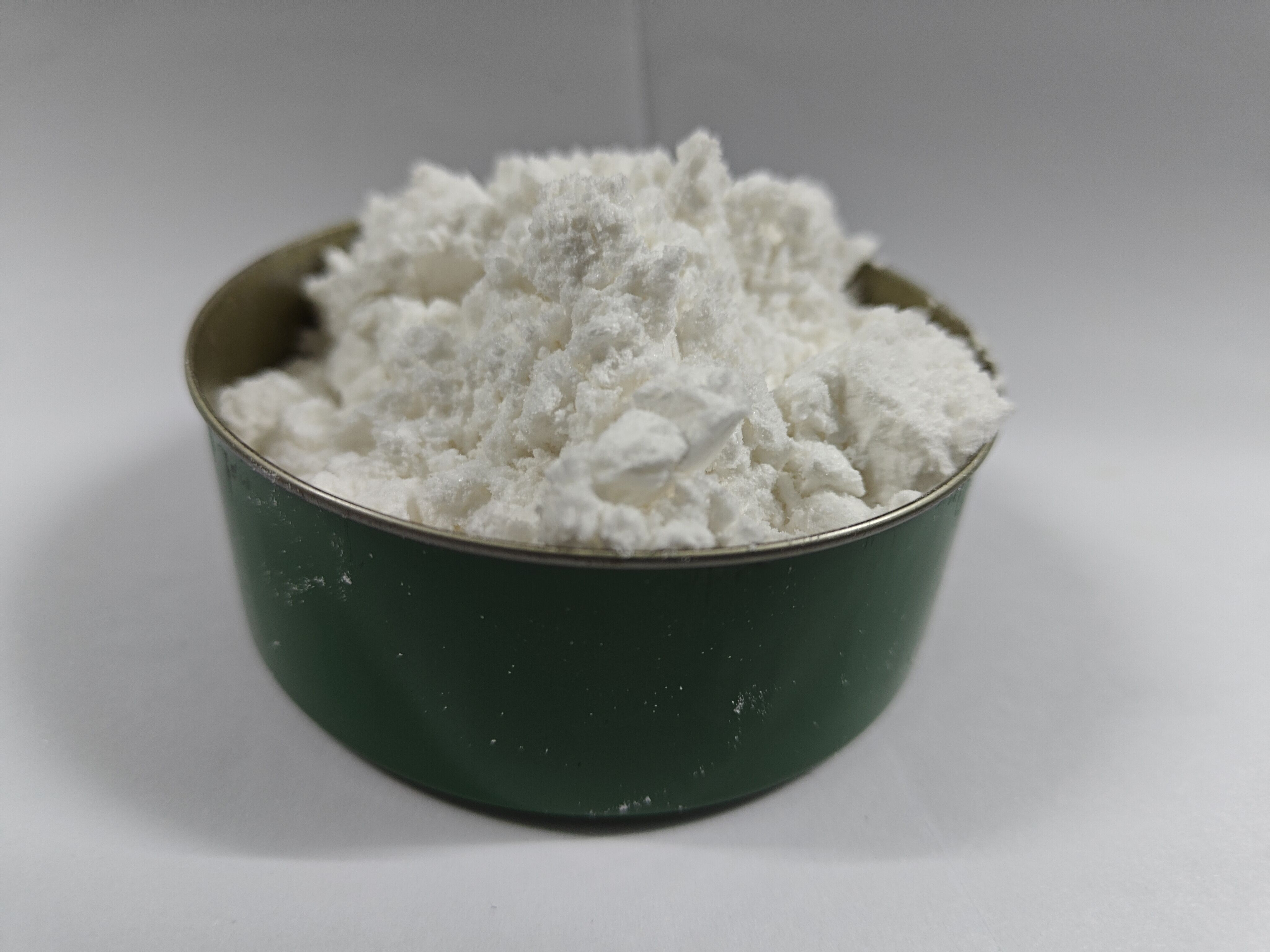

Débloquer une efficacité accrue dans la formation des liaisons amides. Dans la synthèse organique, la formation de liaisons amides reste une réaction fondamentale, notamment en chimie pharmaceutique, des polymères et des peptides. Les chimistes recherchent constamment des réactifs fiables et efficaces pour optimiser ce type de réaction. Les réactifs de type CDI (carbonyldiimidazole) se sont révélés être des outils précieux pour accroître l'efficacité de la formation des liaisons amides, grâce à leur capacité à activer les acides carboxyliques et à faciliter leur réaction avec les amines, conduisant ainsi à des rendements plus élevés et à des conditions de réaction plus douces.

VOIR PLUS