agents et accélérateurs de durcissement emc

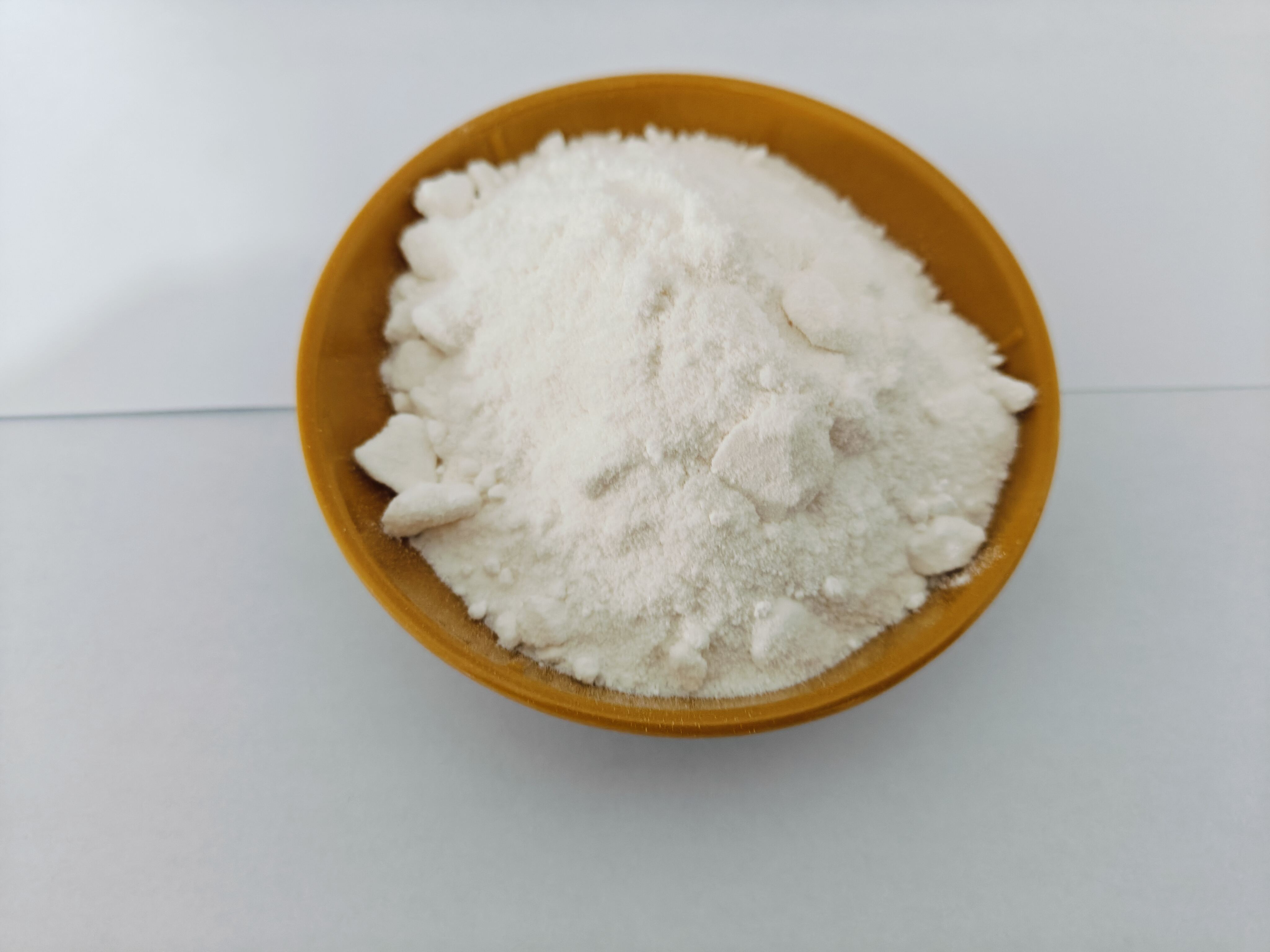

Les agents de durcissement et les accélérateurs EMC sont des composants essentiels dans l'industrie de la fabrication d'électronique, en particulier dans la production de composés de moulage époxy. Ces additifs chimiques spécialisés jouent un rôle crucial dans le contrôle et l'optimisation du processus de durcissement des résines époxy. Les agents de durcissement initient et maintiennent les réactions de liaison croisée qui transforment les résines époxy liquides en matériaux solides et durables, tandis que les accélérateurs améliorent la vitesse et l'efficacité de ce processus. Ces composants sont soigneusement formulés pour obtenir des propriétés spécifiques telles que des taux de durcissement rapides, une excellente adhérence et une résistance thermique optimale. Dans les applications d'emballage électronique, les agents de durcissement et les accélérateurs EMC assurent une bonne encapsulation des dispositifs semi-conducteurs, offrant une protection essentielle contre l'humidité, les contraintes mécaniques et les facteurs environnementaux. La technologie derrière ces matériaux a évolué pour répondre aux exigences de plus en plus exigeantes des appareils électroniques modernes, offrant une meilleure stabilité thermique, des temps de durcissement réduits et une fiabilité accrue. Des formulations avancées permettent désormais de mieux traiter les fluides lors du moulage, de réduire les émissions de composés organiques volatils et d'obtenir des propriétés mécaniques supérieures dans le produit final. Ces matériaux sont largement utilisés dans les emballages de semi-conducteurs, les circuits intégrés et divers composants électroniques où une protection et des performances fiables sont primordiales.