epoxy molding compound uses

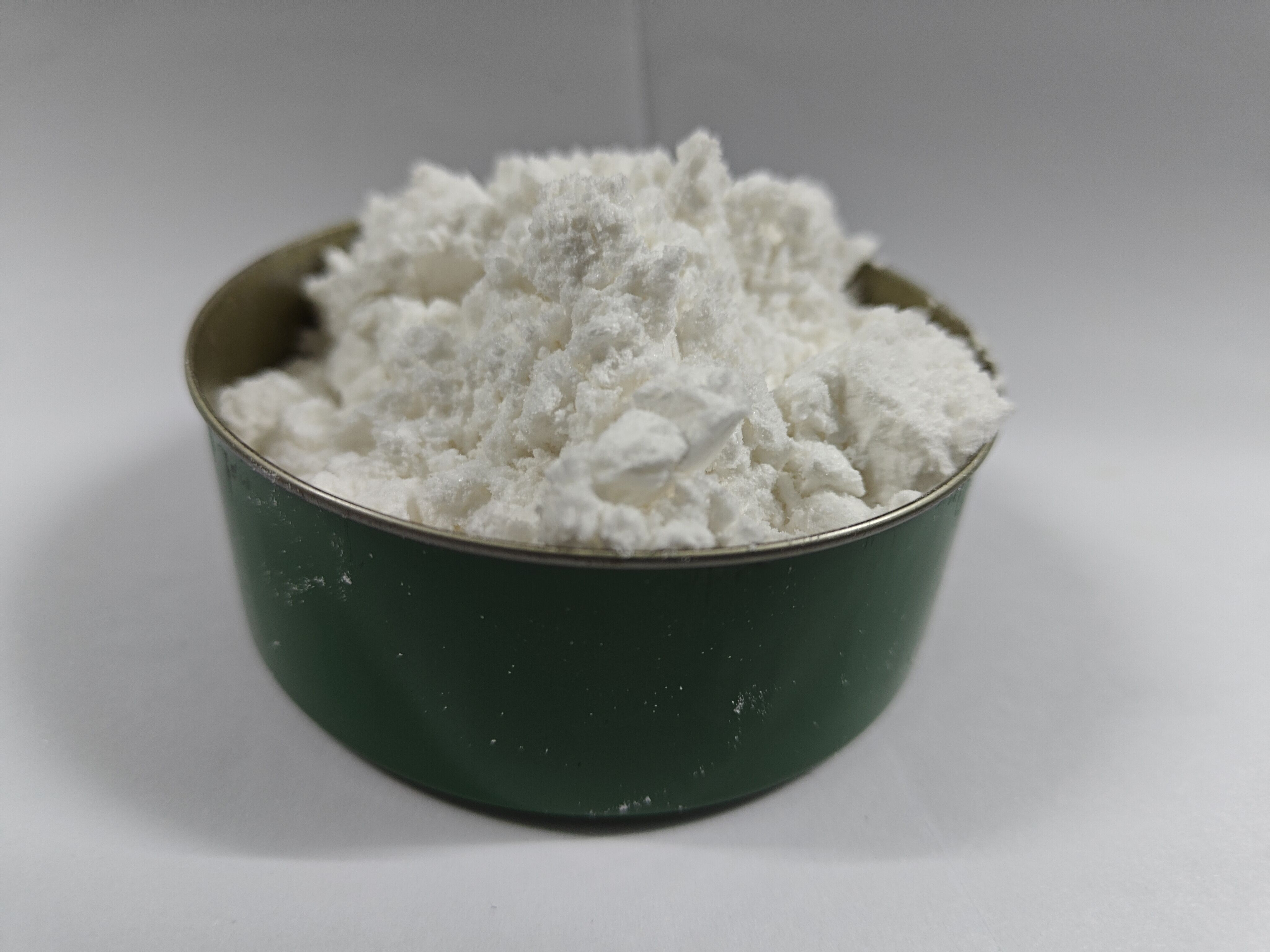

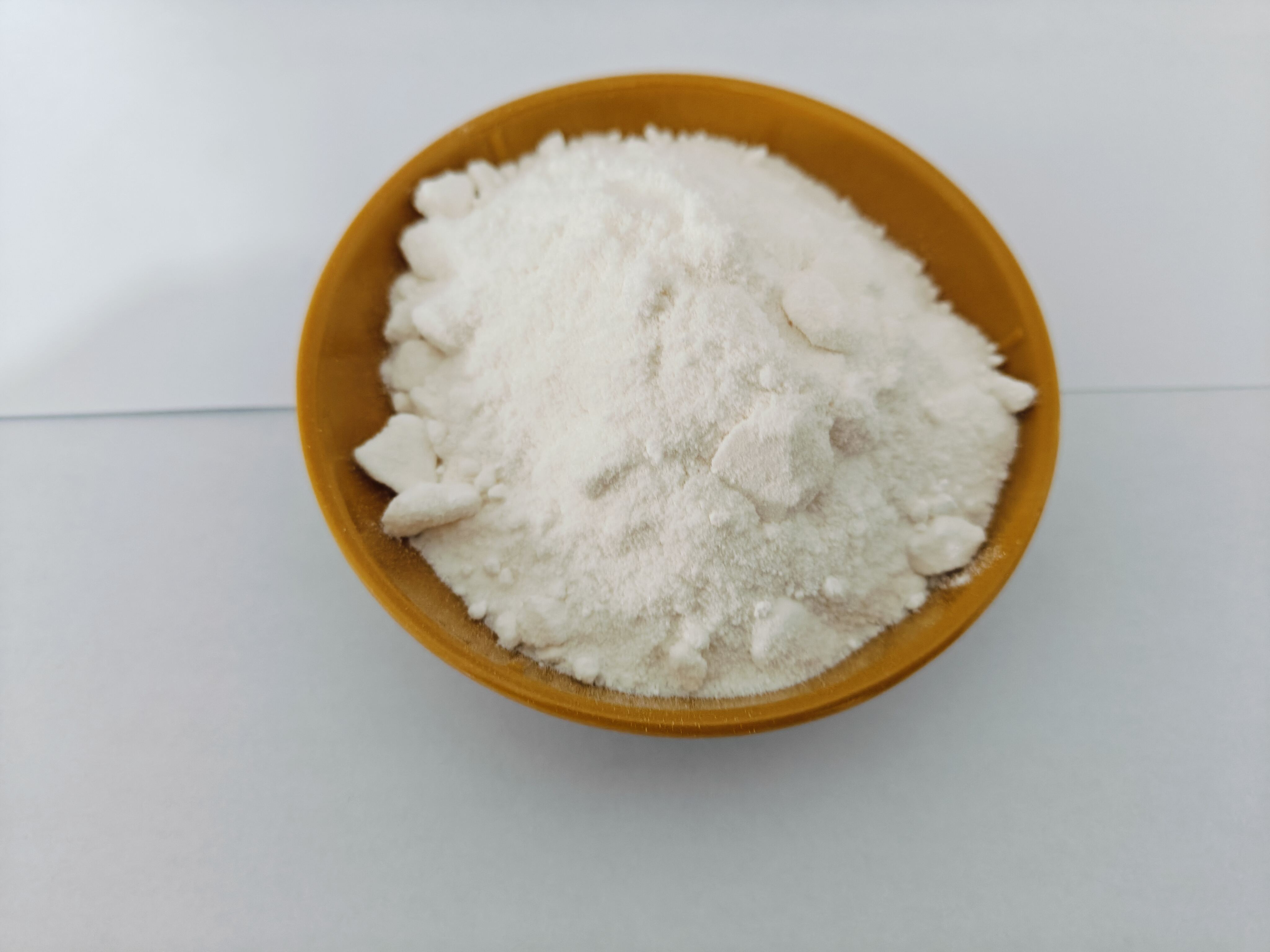

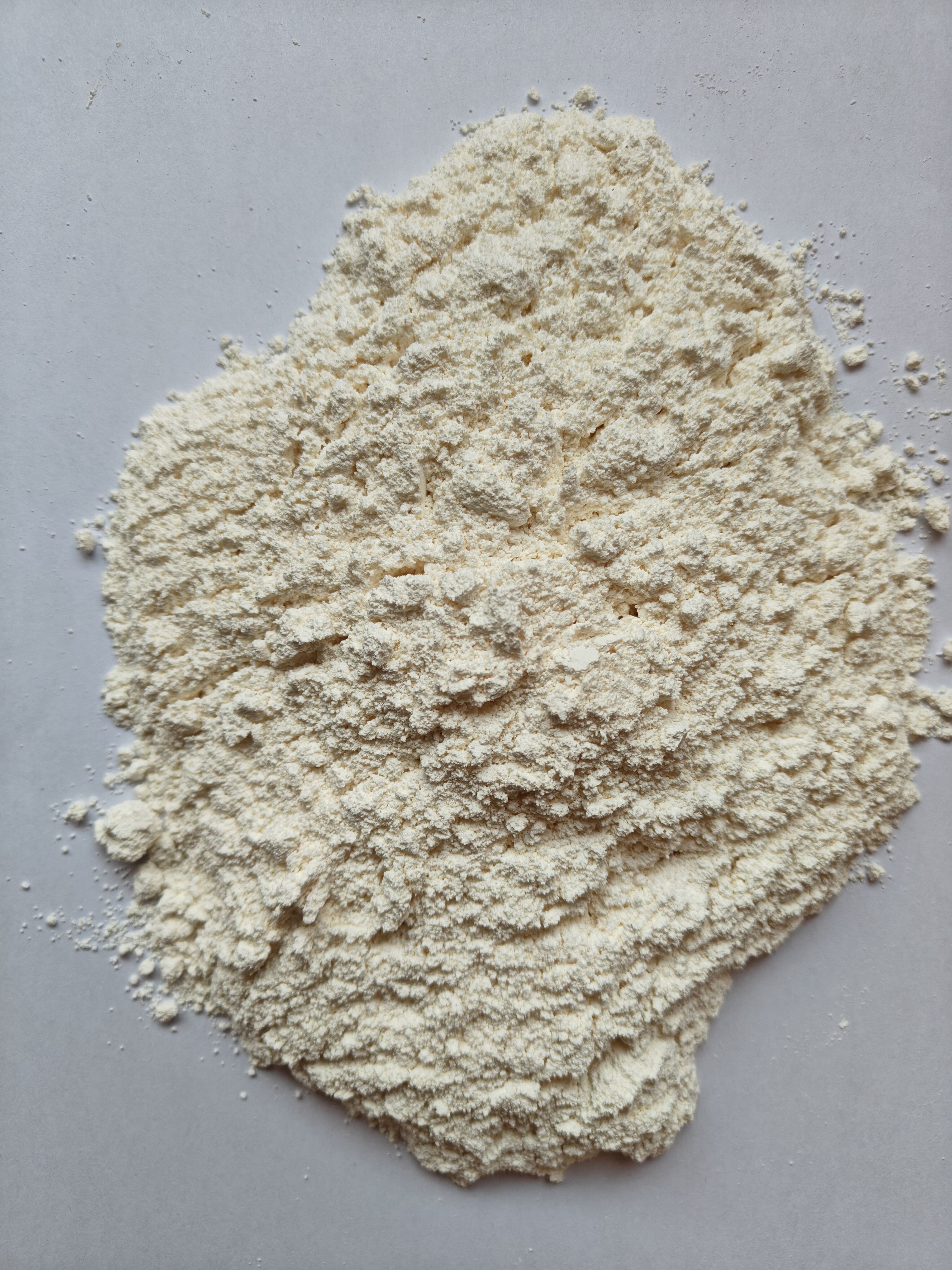

Epoxy molding compound (EMC) serves as a crucial material in the electronic packaging industry, providing essential protection and insulation for semiconductor devices. This versatile material is primarily used to encapsulate integrated circuits, transistors, and other electronic components, creating a protective barrier against environmental factors such as moisture, heat, and mechanical stress. The compound consists of epoxy resin, hardener, and various fillers that contribute to its specific properties. In modern electronics manufacturing, EMC plays a vital role in enhancing device reliability and longevity. Its excellent adhesion properties ensure strong bonding with different substrate materials, while its thermal conductivity helps manage heat dissipation effectively. The material's low coefficient of thermal expansion makes it particularly suitable for applications where temperature fluctuations are common. EMC's electrical insulation properties protect sensitive components from electromagnetic interference and prevent short circuits. The compound's versatility allows manufacturers to adjust its properties according to specific requirements, such as flame retardancy, thermal conductivity, or flow characteristics during the molding process. This adaptability has made EMC an indispensable material in various electronics applications, from consumer devices to automotive electronics and industrial equipment.