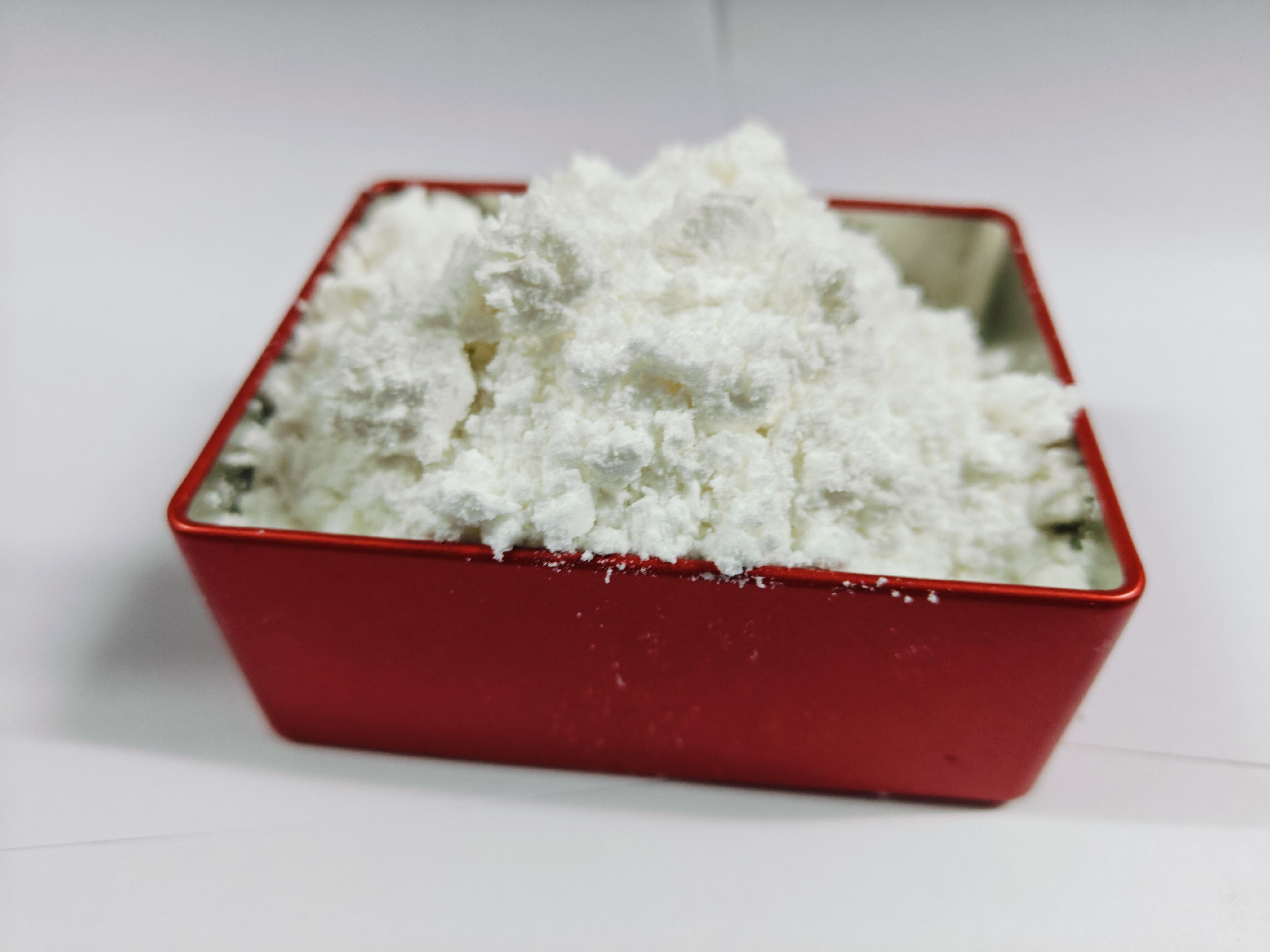

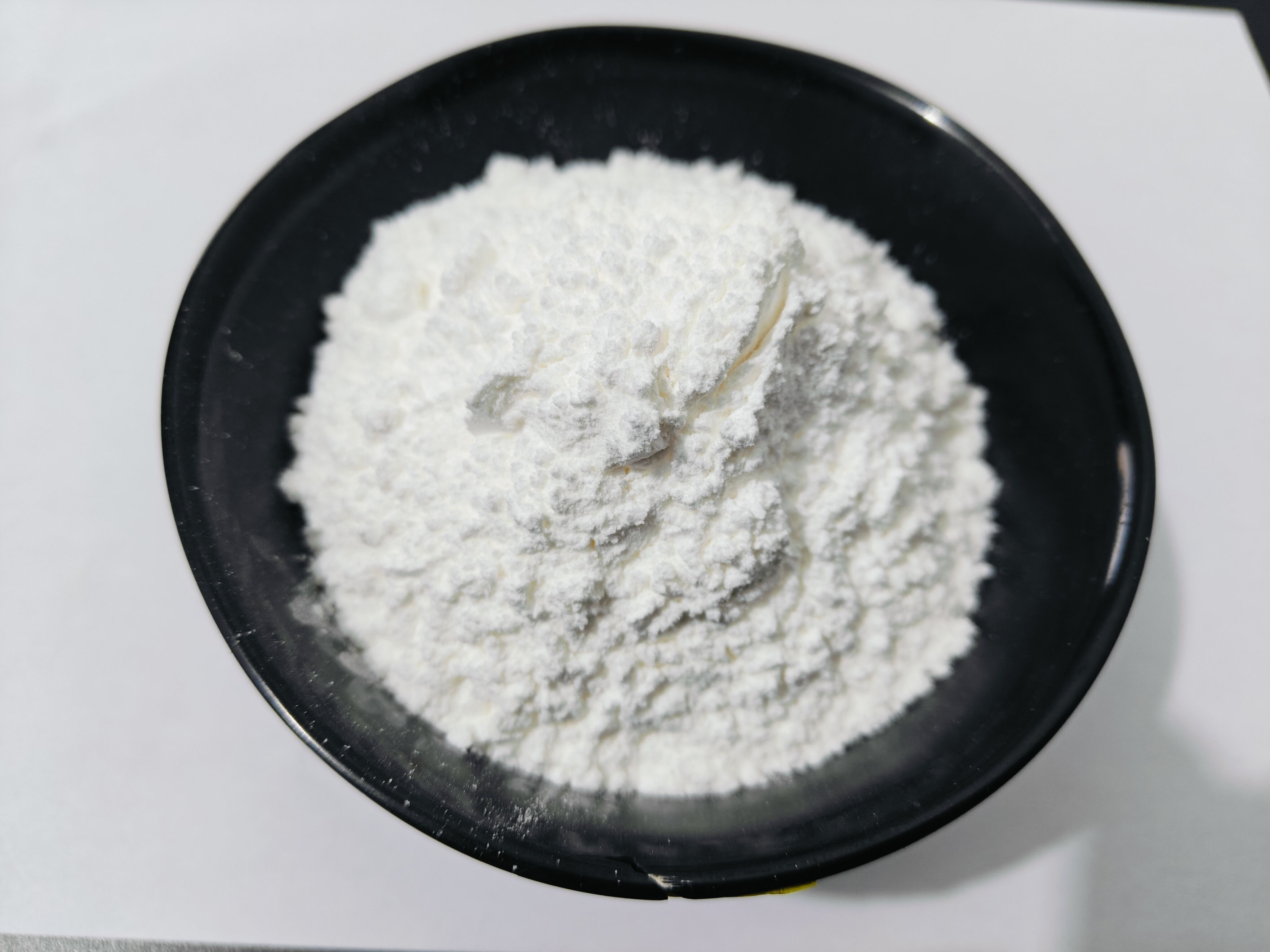

emc ပိုင်းခြံတွင်အသုံးပြုရန် ရွေးချယ်ထားသော အပူချိန်ဆိုင်ရာ ကာတီလိုင်းများ

EMC ပိုင်းခြောက်တွင်ရှိသောအိမ်အားလိုက်ဆိုင်ရာကိုယ်စားလှယ်များသည် အီလက်ထရွန်စ်ပိုင်းခြောက်တွင်ဘာသာရပ်ပညာ၏အသစ်ဖြစ်ပါသည်။ ဒီဇိုင်းမှာ ပိုင်းခြောက်၏အလုပ်လုပ်ဆောင်မှုကိုပိုမိုတိုးတက်စေရန် ကိုယ်စားလှယ်များ၏အလုပ်လုပ်ဆောင်မှုကို ကိုင်တွယ်စွာထုတ်လုပ်ရန်အတွက် အသုံးပြုသည်။ ထိုကိုယ်စားလှယ်များသည် အခြားအပူချိန်များတွင် အလုပ်လုပ်ဆောင်မှုမရှိပဲ အပူချိန်များအတိုင်း ၁၅၀-၂၀၀°C အကြားတွင်သာ အလုပ်လုပ်ဆောင်သည်။ ကိုယ်စားလှယ်များသည် အလုပ်လုပ်ဆောင်မှုကို အချိန်အကြားတွင် အပြီးဆုံးဖြစ်စေရန် အပြတ်အဆိုးအဖြစ် အသုံးပြုသည့်အပြင် ပိုင်းခြောက်အတွင်းရှိ အလုပ်လုပ်ဆောင်မှုကို ကိုင်တွယ်စွာထုတ်လုပ်ရန်အတွက် အသုံးပြုသည်။ အပူချိန်အခြေခံသောအခြေအနေများတွင် အပြတ်အဆိုးများသည် ခွဲခြားနေသောအခါ ကိုယ်စားလှယ်များ၏အလုပ်လုပ်ဆောင်မှုကို ဖြန့်ဖြူးပေးသည်။ ဒီဇိုင်းမှာ ပိုင်းခြောက်အတွင်းရှိ အလုပ်လုပ်ဆောင်မှုကို ကိုင်တွယ်စွာထုတ်လုပ်ရန်အတွက် အသုံးပြုသည့်အပြင် ပိုင်းခြောက်အတွင်းရှိ အလုပ်လုပ်ဆောင်မှုကို ကိုင်တွယ်စွာထုတ်လုပ်ရန်အတွက် အသုံးပြုသည်။ ကိုယ်စားလှယ်များသည် EMC ပိုင်းခြောက်တွင်အသုံးပြုသော အီပေါက်ဆိုဒ်များနှင့် ဟာဒင်နာများနှင့်အတူ အလုပ်လုပ်ဆောင်မှုကို ကိုင်တွယ်စွာထုတ်လုပ်ရန်အတွက် အသုံးပြုသည်။ ဒီဇိုင်းမှာ ပိုင်းခြောက်အတွင်းရှိ အလုပ်လုပ်ဆောင်မှုကို ကိုင်တွယ်စွာထုတ်လုပ်ရန်အတွက် အသုံးပြုသည်။ ကိုယ်စားလှယ်များ၏အသုံးပြုမှုသည် ပိုင်းခြောက်များကို ပိုမိုကောင်းစွာထိန်းသိမ်းပေးသည်။