thermally latent catalyst suppliers

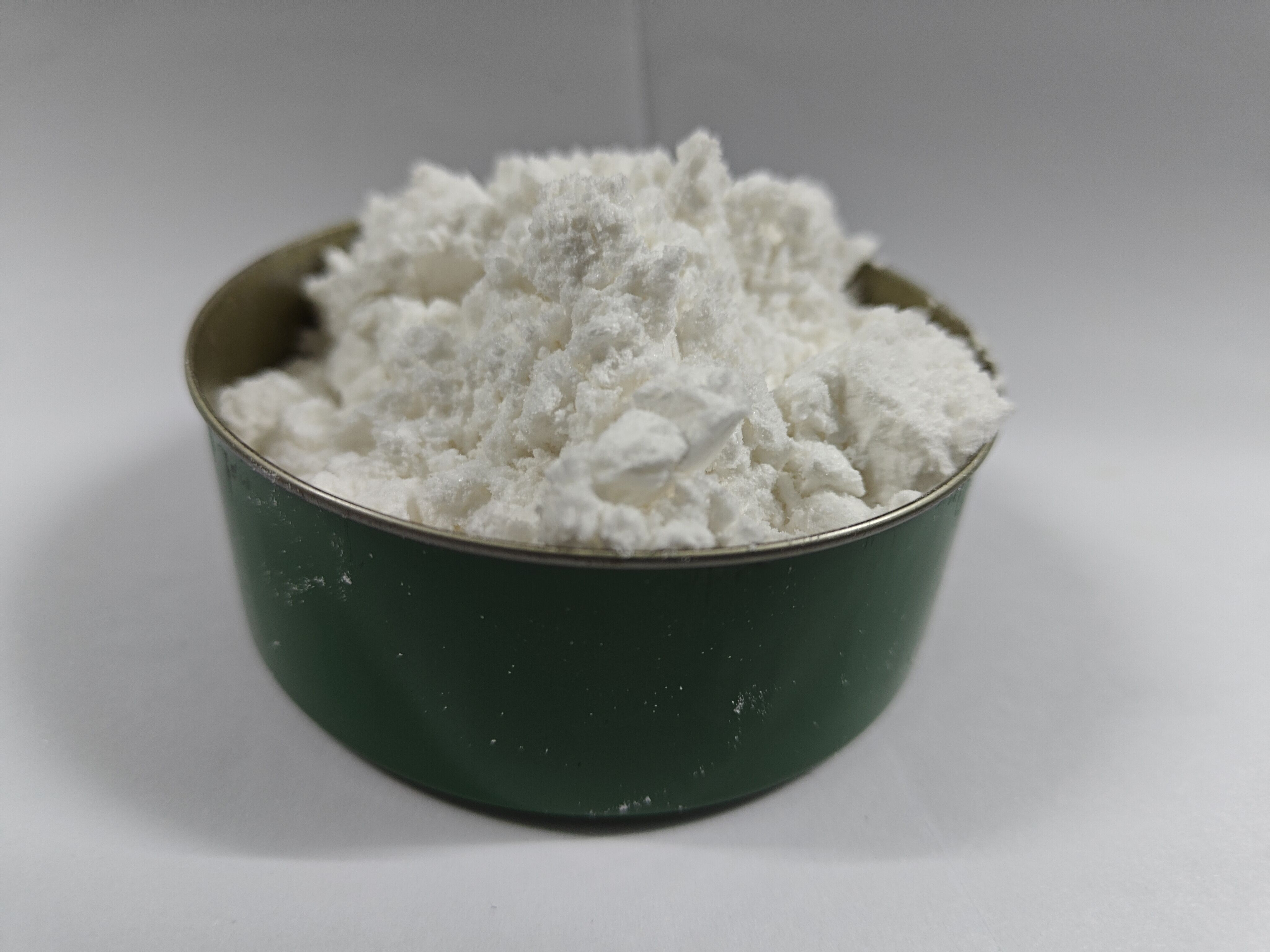

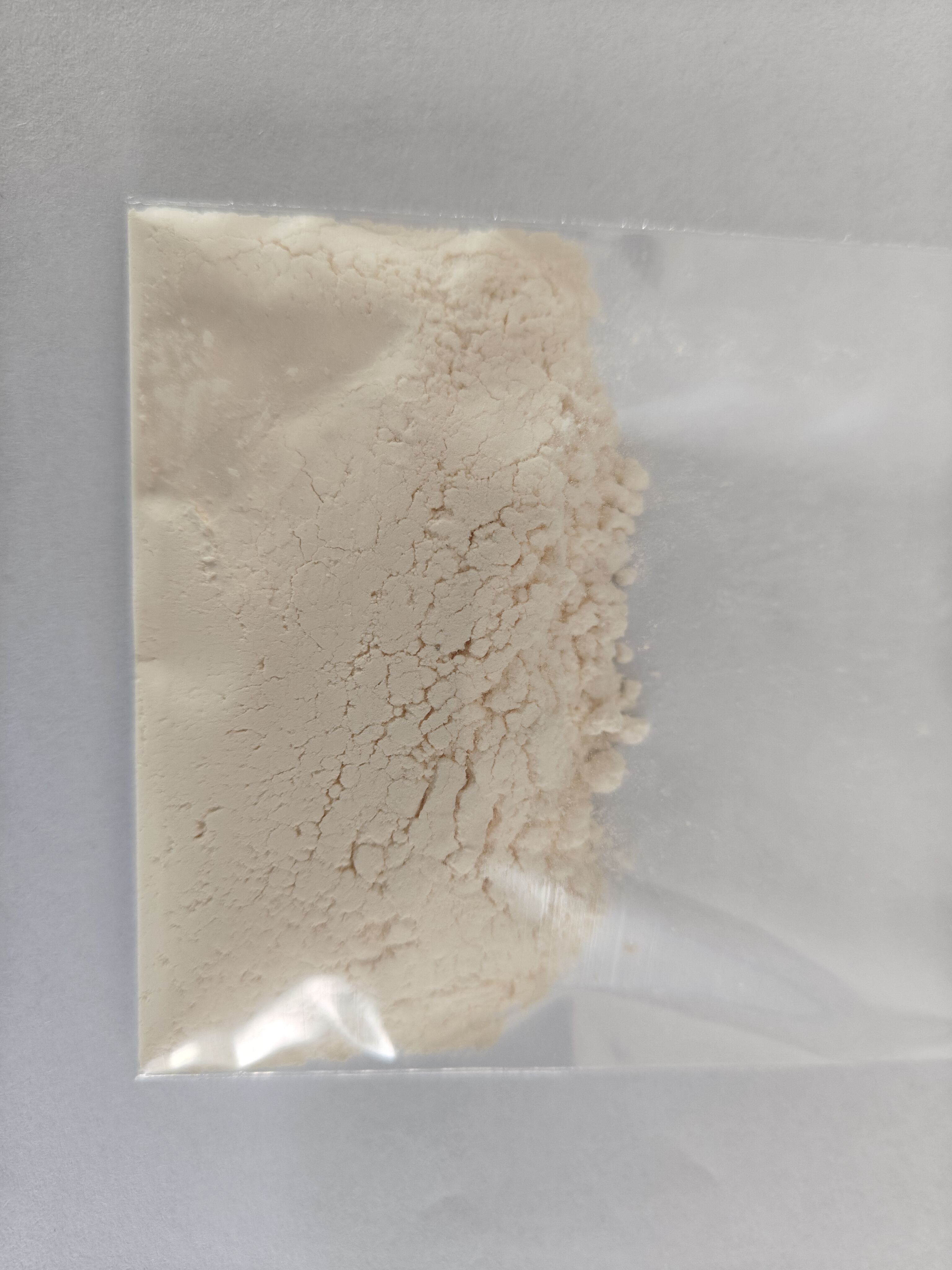

Thermally latent catalyst suppliers play a crucial role in providing specialized catalysts that remain inactive at room temperature but become highly active when exposed to specific temperature conditions. These suppliers offer innovative solutions for various industrial processes, particularly in polymer chemistry and coating applications. The catalysts they provide are engineered to initiate chemical reactions only when heated to predetermined temperatures, allowing for better control over reaction timing and processing conditions. Their product portfolio typically includes both organic and inorganic catalyst systems, designed to meet diverse application requirements across multiple industries. These suppliers maintain strict quality control measures to ensure consistent product performance and reliability. They often provide technical support and customization services to help clients optimize catalyst performance for specific applications. Modern thermally latent catalysts feature advanced molecular designs that enable precise activation temperatures and controlled reaction rates. Suppliers also focus on developing environmentally friendly options that reduce volatile organic compound emissions and improve workplace safety. They typically offer comprehensive documentation, including detailed technical specifications and safety data sheets, to support regulatory compliance and proper handling procedures.