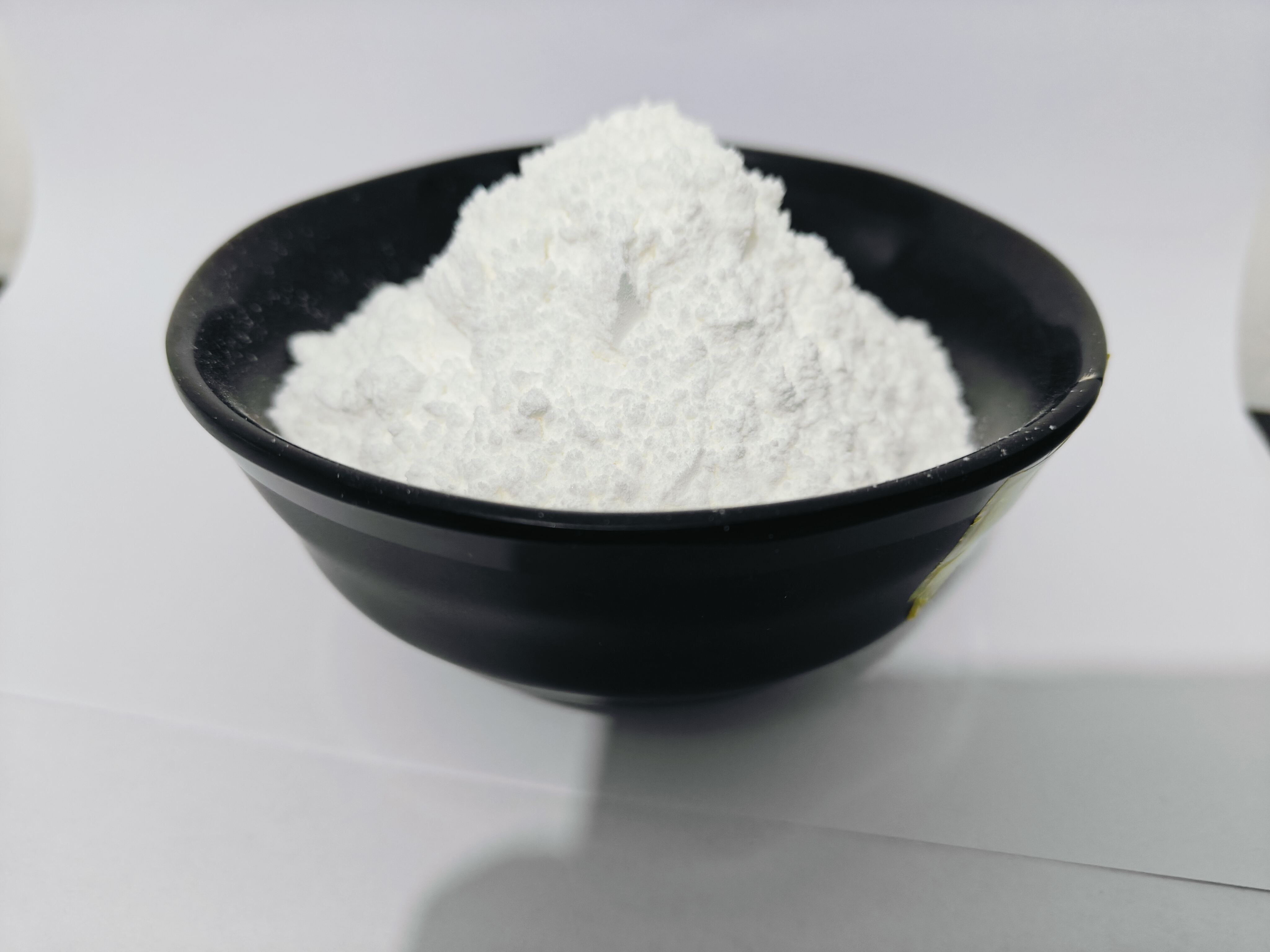

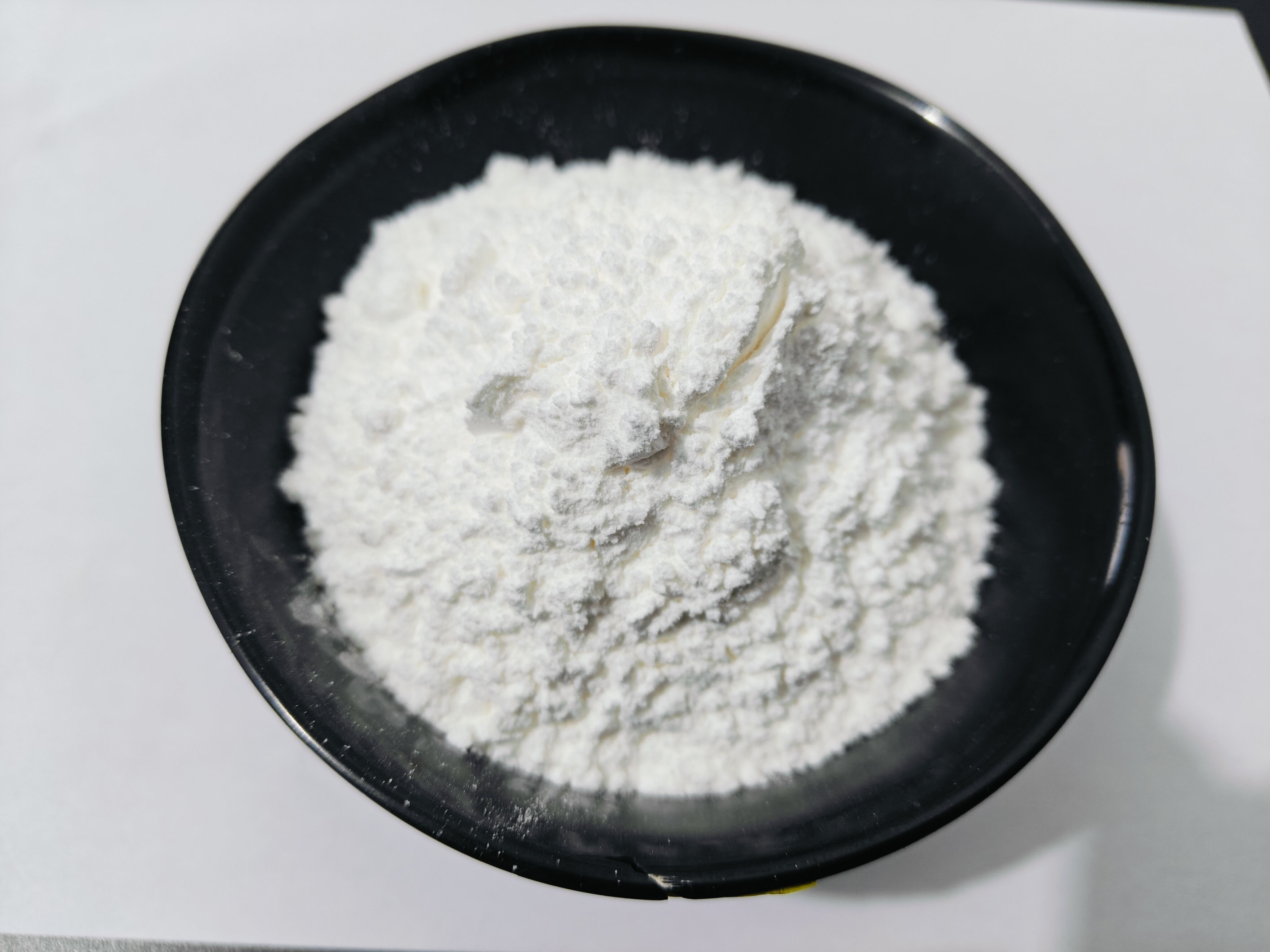

Az epoxi öntőmasszák lényeges anyagok az elektronikai gyártásban, de a tárolási stabilitásuk jelentős kihívásokat jelent a gyártók és beszállítók számára. A megoldás kulcsa abban rejlik, hogy hogyan hővel aktiválható katalizátorok , különösen a 2-fenil-4-metil-1H-imidazol, forradalmasítja ezeknek az anyagoknak a tárolási és feldolgozási tulajdonságait. Ezek a speciális katalizátorok szobahőmérsékleten inaktívak maradnak, miközben gyors aktiválódást biztosítanak a formázási folyamat során hő hatására.

Termikusan látens katalizátorok megértése epoxi rendszerekben

Kémiai szerkezet és aktiválási mechanizmus

A termikusan látens katalizátorok olyan speciálisan tervezett vegyületek, amelyek környezeti hőmérsékleten minimális katalitikus aktivitást mutatnak, de magasabb hőmérsékleten kitűnően aktívvá válnak. A 2-fenil-4-metil-1H-imidazol szerkezet olyan imidazolgyűrűt tartalmaz, amelyen fenil- és metil-csoportok találhatók, és ezek befolyásolják a termikus aktivációs profilt. Ez a molekuláris felépítés biztosítja, hogy a katalizátor tárolás közben stabil maradjon, ugyanakkor kiváló reaktivitást biztosítson feldolgozás során.

Az aktivációs mechanizmus során hőenergia bontja a katalizátor molekulában található specifikus kötéseket, aktív fajokat hozva létre, amelyek elindítják az epoxi keményedési reakciót. Ez a szabályozott aktiváció megakadályozza a korai zselésedést tárolás közben, miközben biztosítja a gyors keményedést hő hatására. A fenilcsoport további stabilitást biztosít a rezonanciahatás révén, míg a metilcsoport finomhangolja az aktiválási hőmérsékletet.

Összehasonlítás a hagyományos katalizátorokkal

A hagyományos amin katalizátorok gyakran magas aktivitást mutatnak szobahőmérsékleten, ami csökkentett hasznos élettartamhoz és tárolási stabilitási problémákhoz vezet. Ezzel szemben a termikusan latens katalizátorok, mint például a 2-fenil-4-metil-1H-imidazol, kiválóbb tárolási jellemzőkkel rendelkeznek, miközben kitűnő feldolgozási teljesítményt is biztosítanak. A latens jelleg sok alkalmazásban megszünteti a hűtött tárolás szükségességét.

A hagyományos rendszerek összetett formulázási módosításokat igényelhetnek a reaktivitás és a tárolási élettartam közötti egyensúlyozáshoz, de a termikusan látens katalizátorok elegáns megoldást nyújtanak, amely egyszerre kezeli mindkét követelményt. Ez az előny különösen értékes ipari alkalmazásokban, ahol hosszú tárolási időszakok szükségesek.

A tárolási állapot stabilitásának mechanizmusai és előnyei

Molekuláris stabilitás normál körülmények között

A 2-fenil-4-metil-1H-imidazol molekuláris szerkezete kiváló stabilitást biztosít normál tárolási körülmények között. Az imidazolgyűrű sértetlen marad a aktiválási hőmérsékleti küszöb alatt, így megakadályozza az epoxi csoportokkal történő kívülálló reakciókat. Ez a stabilitás közvetlenül hosszabb felhasználhatósági időt jelent az epoxi öntőmasszák számára.

A tárolási stabilitás vizsgálatok azt mutatják, hogy az ezzel a katalizátorral ellátott vegyületek hónapokon át megőrzik feldolgozási jellemzőiket szobahőmérsékleten. A korai keresztkötési reakciók hiánya biztosítja az állandó viszkozitást és áramlási tulajdonságokat a tárolás teljes időtartama alatt. Ez az előrejelezhetőség elengedhetetlen a gyártási műveletekhez, amelyek megbízható anyagjellemzőket igényelnek.

Korai keresztkötés megelőzése

A korai keresztkötés az epoxigyanták tárolása során egyik legjelentősebb kihívást jelenti. A hagyományos katalizátorok lassú reakciókat indíthatnak még szobahőmérsékleten is, ami fokozatosan növekvő viszkozitáshoz és végül gélképződéshez vezethet. A termikusan latens katalizátorok hatékonyan kiküszöbölik ezt a problémát, mivel addig inaktívak maradnak, amíg szándékosan nem aktiválják őket.

A 2-fenil-4-metil-1H-imidazol szabályozott aktiválási hőmérséklete biztosítja, hogy a keresztkötés csak a szándékolt formázási folyamat során következzen be. Ez a pontosság lehetővé teszi a gyártók számára, hogy állandó anyagjellemzőket tartsanak fenn, és kiküszöböljék a korai térhálósodással járó hulladékot. Ennek eredménye a javult készletgazdálkodás és az alacsonyabb anyagköltségek.

Feldolgozási előnyök és teljesítményjellemzők

Gyors aktiválás és térhálósodási kinetika

Hő hatására a 2-fenil-4-metil-1H-imidazol kiváló katalitikus aktivitást mutat az epoxigyanták térhálósítási reakcióiban. Az aktiválási hőmérséklet pontosan szabályozható a formuláció módosításával, lehetővé téve az optimalizálást adott feldolgozási körülményekhez. Az aktiválás után a katalizátor gyors és teljes térhálósodást indít az epoximátrixban.

A térhálósodási kinetikai profil kezdeti késleltetést mutat, majd gyors felgyorsulás következik be az aktiválási hőmérséklet elérése után. Ez a viselkedés kiváló ellenőrzést biztosít az öntési folyamat során, és egységes térhálósodást garantál összetett geometriák esetén is. Az előrejelezhető kinetika lehetővé teszi az optimális ciklusidők meghatározását és a termelékenység javítását.

Hőmérséklet-szabályozás és folyamatoptimalizálás

A termikusan latens katalizátorok használata miatt a folyamatoptimalizálás egyszerűbbé válik, mivel aktiválódási viselkedésük előrejelezhető. A tárolási és feldolgozási hőmérsékletek közötti egyértelmű különbség kiküszöböli a találgatást a hőmérsékletszabályozó rendszerekben. A gyártók pontos, hatékonyságot maximalizáló fűtési profilokat állíthatnak fel, miközben biztosítják a teljes térhálósodást.

Az ezekben a katalizátorokban rejlő széles feldolgozási ablak lehetővé teszi a hőmérsékleti gradiens és az egyenletes melegedés változékonyságának kezelését. Ez a rugalmasság különösen értékes nagy léptékű formázási műveletek esetén, ahol hőmérsékletkülönbségek fordulhatnak elő az öntőformán belül. A robusztus aktiválódási mechanizmus biztosítja az egész öntött alkatrész egységes tulajdonságait.

Ipari alkalmazások és piaci hatás

Elektronika és félvezető becsomagolás

Az elektronikai ipar jelenti a termikusan latens katalizátorokat tartalmazó epoxigyanta-formázó anyagok legnagyobb piacát. A félvezető-csomagolási alkalmazások olyan anyagokat igényelnek, amelyek rendkívül jó tárolási stabilitással és megbízható feldolgozási jellemzőkkel rendelkeznek. A 2-fenil-4-metil-1H-imidazol használata lehetővé teszi a gyártók számára, hogy nagy készleteket tartsanak fenn anyagromlás veszélye nélkül.

A fejlett csomagolási technológiák, mint például a rendszer-csomagban (system-in-package) és a 3D integráció, jelentősen profitálnak a hőre rejtett katalizátorok által nyújtott pontos szabályozásból. Ezek az alkalmazások gyakran összetett hőprofilokat és hosszabb feldolgozási időket igényelnek, ami miatt a katalizátor stabilitása döntő fontosságú a sikerhez. Az előrejelezhető aktiválási viselkedés biztosítja az egységes bevonási minőséget különböző csomagolási típusok esetén.

Autóipari és ipari alkalmazások

Az autóipari elektronika egyre inkább az epoxi öntővegyületekre támaszkodik a környezeti védelem és mechanikai stabilitás érdekében. Az autóipari alkalmazásokban uralkodó kemény működési körülmények olyan anyagokat igényelnek, amelyek kiváló hosszú távú stabilitással és megbízhatósággal rendelkeznek. A hőre rejtett katalizátorok hozzájárulnak a jobb anyagteljesítményhez, mivel teljes térhálósodást és optimális keresztkötési sűrűséget biztosítanak.

Az ipari alkalmazások, a teljesítményelektronikától kezdve a szenzorcsomagolásig, hasznot húznak ezen fejlett katalizátorrendszerek hosszabb tárolási élettartamából és feldolgozási rugalmasságából. Az anyagok szobahőmérsékleten történő tárolásának képessége csökkenti a logisztikai költségeket, és leegyszerűsíti az alapanyag-ellátási láncok globális készletgazdálkodását.

Összetétel szempontjai és optimalizálás

Katalizátor mennyisége és eloszlása

Az optimális katalizátor mennyiség a kívánt polimerizációs sebességtől, tárolási igényektől és feldolgozási feltételektől függ. A 2-fenil-4-metil-1H-imidazol tipikus mennyisége általában 1–5 rész száz gyantaegységenként, ahol a magasabb koncentráció gyorsabb térhálósodást eredményez, de potenciálisan rövidebb tárolási élettartammal jár. A kívánt teljesítményjellemzők eléréséhez gondos egyensúlyt kell találni.

Az egységes katalizátor-eloszlás az összetevőn belül elengedhetetlen a konzisztens térhálósodási viselkedéshez. A fejlett keverési technikák homogén eloszlást biztosítanak, miközben minimalizálják a hőterhelést a feldolgozás során. A katalizátor részecskemérete és felületkezelése befolyásolhatja az eloszlást és az aktiválási jellemzőket.

Szinergikus hatások más adalékanyagokkal

A termikusan latens katalizátorok teljesítménye javítható a ko-katalizátorok és gyorsítók gondos kiválasztásával. Bizonyos szerves vegyületek módosíthatják az aktiválási hőmérsékletet vagy a térhálósodási sebességet, így jobban illeszkedve a konkrét feldolgozási igényekhez. Ezek a szinergikus hatások lehetővé teszik az egész rendszer teljesítményének finomhangolását.

Az égésállóságot javító anyagokkal, töltőanyagokkal és egyéb adalékokkal való kompatibilitást a formuláció kifejlesztése során figyelembe kell venni. Egyes adalékok hatással lehetnek a katalizátorrendszerre, így befolyásolhatják a tárolási stabilitást vagy az aktiválódási viselkedést. A teljes körű tesztelés biztosítja, hogy minden komponens hatékonyan együttműködjön a kívánt tulajdonságok elérése érdekében.

Minőségellenőrzés és vizsgálati módszerek

Tárolási stabilitás értékelése

A gyorsított öregítési vizsgálatok fontos betekintést nyújtanak a hőre rejtett katalizátorokat tartalmazó epoxi vegyületek hosszú távú tárolási stabilitásába. Ezek a vizsgálatok általában emelt hőmérsékleten történő kitettséget jelentenek, miközben a viszkozitás-változásokat és a zselési idő alakulását figyelik meg. Az eredmények segítenek előrejelezni az eltarthatóságot normál tárolási körülmények között.

A hosszú távú stabilitási vizsgálatok kiegészítik a gyorsított teszteket, mivel tényleges teljesítményadatokat szolgáltatnak meghosszabbított időszakok alatt. Ezek a vizsgálatok nyomon követik a kulcsfontosságú tulajdonságokat, mint például az áramlási jellemzők, a polimerizációs viselkedés és a végső mechanikai tulajdonságok. Az adatok alátámasztják a felhasználhatósági időtartamra vonatkozó állításokat, és segítenek az optimális tárolási javaslatok meghatározásában.

Folyamatfigyelés és -szabályozás

Az hatékony folyamatirányítás olyan figyelőrendszereket igényel, amelyek képesek a katalizátor aktiválódásának és a polimerizáció előrehaladásának nyomon követésére. A termikus analízis módszerek, mint például a differenciális pásztázó kalorimetria részletes információkat szolgáltatnak az aktiválódási hőmérsékletekről és a polimerizációs kinetikáról. Ezek az adatok lehetővé teszik a feldolgozási paraméterek optimalizálását és a minőségbiztosítást.

Az inline monitorozó rendszerek nyomon követhetik a hőmérsékleti profilokat és a polimerizációs állapotot a gyártás során, így biztosítva az egységes termékminőséget. A fejlett érzékelők és szabályozó algoritmusok segítenek fenntartani az optimális feldolgozási körülményeket, miközben kompenzálják a normál folyamateltéréseket. Ez a szintű irányítás elengedhetetlen a nagyüzemi gyártási műveletekhez.

Jövőbeli fejlesztések és trendek

Korszerű katalizátor tervezések

A kutatások folytatódnak az új, termikusan latens katalizátorstruktúrák terén, amelyek javított teljesítményjellemzőket kínálnak. Az új típusú imidazol származékok módosított helyettesítő csoportokkal ígéretesek olyan alkalmazásokhoz, amelyek specifikus aktiválási hőmérsékletet vagy javított tárolási stabilitást igényelnek. Ezek a fejlesztések új alkalmazásokat és feldolgozási módszereket tehetnek lehetővé.

Az inkapszulálási technikák egy másik irányt jelentenek a katalizátorok fejlesztésében, potenciálisan még nagyobb kontrollt engedve az aktiválási viselkedés felett. A mikroinkapszulált katalizátorok pontos időzítést biztosíthatnak az aktiválási eseményekhez, és többfokozatú térhálósodási folyamatokat tehetnek lehetővé. Ilyen innovációk kiterjesztenék a termikusan latens rendszerek sokoldalúságát.

Fenntarthatóság és környezetvédelmi szempontok

A környezetvédelmi szabályozások és a fenntarthatóság miatt kialakuló aggodalmak ösztönzik a környezetbarátabb katalizátorrendszerek kifejlesztését. A jövőbeni készítmények biobázisú összetevőket is tartalmazhatnak, vagy potenciálisan problémás anyagokat is kizárhatnak, miközben a teljesítmény előnyeit megőrzik. A hő-latens rendszerek hosszú tárolási ideje már hozzájárul a hulladékcsökkentéshez és a fenntarthatóság javításához.

A katalizátorrendszerek életciklusának értékelése a nyersanyag-termeléstől a lejárt hulladékok ártalmatlanításáig terjedő tényezőket veszi figyelembe. A hő-latens katalizátorok hatékonyságuk és csökkentett feldolgozási energiaigényeik miatt gyakran kedvező pontszámot szereznek. Ezek az előnyök támogatják a környezettudatos alkalmazások alkalmazását.

GYIK

Mi különbözteti meg a hagyományos katalizátorokat a hő-latens katalizátoroktól?

A hő-latens katalizátorok a szobahőmérsékleten lényegében inaktívak maradnak, kiváló tárolási stabilitást biztosítva, míg a hagyományos katalizátorok gyakran bizonyos aktivitást mutatnak még környezeti körülmények között is. Ez a különbség lehetővé teszi, hogy az epoxidvegyületeket hosszabb ideig tárolhassák, anélkül, hogy előzetes keményezésre vagy viszkozitásnövekedésre kerülne sor. A latens katalizátorok csak akkor válnak aktívvá, ha a feldolgozás során a specifikus aktivációs hőmérsékletükre melegítik őket.

Mennyi ideig tárolhatók a hő-latens katalizátorokkal ellátott epoxidformáló vegyületek?

A tárolási idő a specifikus készítmény és tárolási feltételektől függ, de a 2- fenil-4- metil-1H- imidazolot tartalmazó vegyületek jellemzően 6-12 hónapig tartják meg tulajdonságaikat szobahőmérsékleten. Egyes készítmények megfelelő csomagolási és tárolási feltételek mellett még hosszabb tárolási időtartamokat is elérhetnek. A meghosszabbított eltarthatósági idő jelentősen csökkenti a hulladékot, és javítja a készletkezelést a hagyományos rendszerekkel összehasonlítva.

Van-e bármilyen feldolgozási korlátozás a hő-latens katalizátorokkal?

A fő szempont a katalizátorrendszer aktiválásához szükséges megfelelő hőmérséklet biztosítása. A feldolgozási hőmérsékleteknek el kell érniük az aktiválódáshoz szükséges küszöbértéket, amely magasabb lehet, mint néhány hagyományos rendszer esetében. Azonban egyszer aktiválódás után ezek a katalizátorok gyakran gyorsabb térhálósodási sebességet és jobb szabályozhatóságot biztosítanak. A feldolgozási ablak általában tágabb, így nagyobb rugalmasságot kínál a gyártási műveletek során.

Használhatók-e termikusan latens katalizátorok minden epoxi alkalmazásban?

Bár a termikusan latens katalizátorok kiválóan alkalmasak öntőmassza-alkalmazásokra, előfordulhat, hogy nem megfelelők szobahőmérsékleten történő térhálósítású rendszerekhez vagy alacsony feldolgozási hőmérsékletet igénylő alkalmazásokhoz. A választás a térhálósítási hőmérséklettől, tárolási igényektől és feldolgozási körülményektől függő konkrét teljesítménnyel kapcsolatos követelményektől függ. A legtöbb magas hőmérsékletű öntési alkalmazás jelentősen profitál ezektől a fejlett katalizátorrendszerektől.

Tartalomjegyzék

- Termikusan látens katalizátorok megértése epoxi rendszerekben

- A tárolási állapot stabilitásának mechanizmusai és előnyei

- Feldolgozási előnyök és teljesítményjellemzők

- Ipari alkalmazások és piaci hatás

- Összetétel szempontjai és optimalizálás

- Minőségellenőrzés és vizsgálati módszerek

- Jövőbeli fejlesztések és trendek

-

GYIK

- Mi különbözteti meg a hagyományos katalizátorokat a hő-latens katalizátoroktól?

- Mennyi ideig tárolhatók a hő-latens katalizátorokkal ellátott epoxidformáló vegyületek?

- Van-e bármilyen feldolgozási korlátozás a hő-latens katalizátorokkal?

- Használhatók-e termikusan latens katalizátorok minden epoxi alkalmazásban?