viscosité de fusion pour le moulage emc

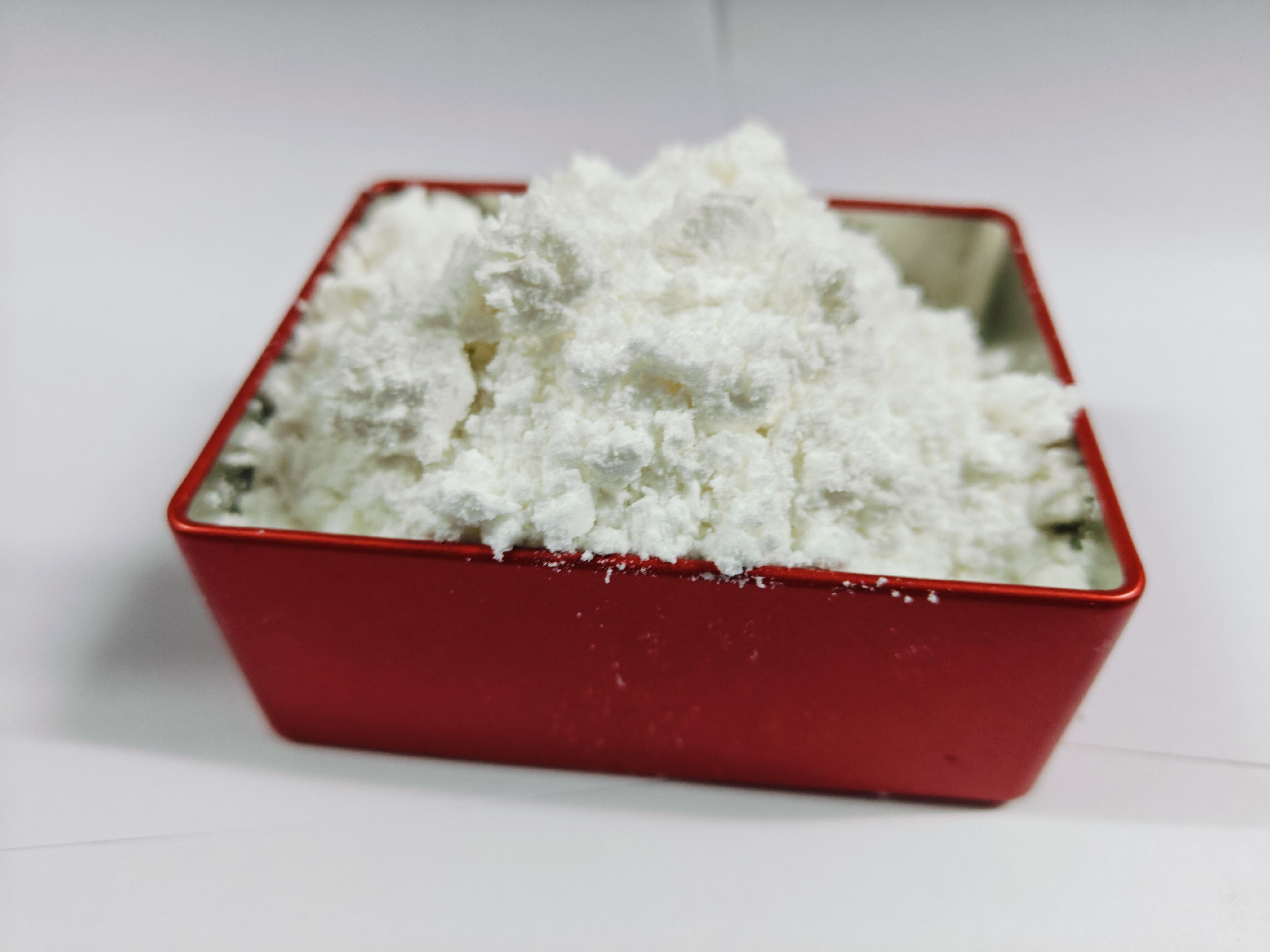

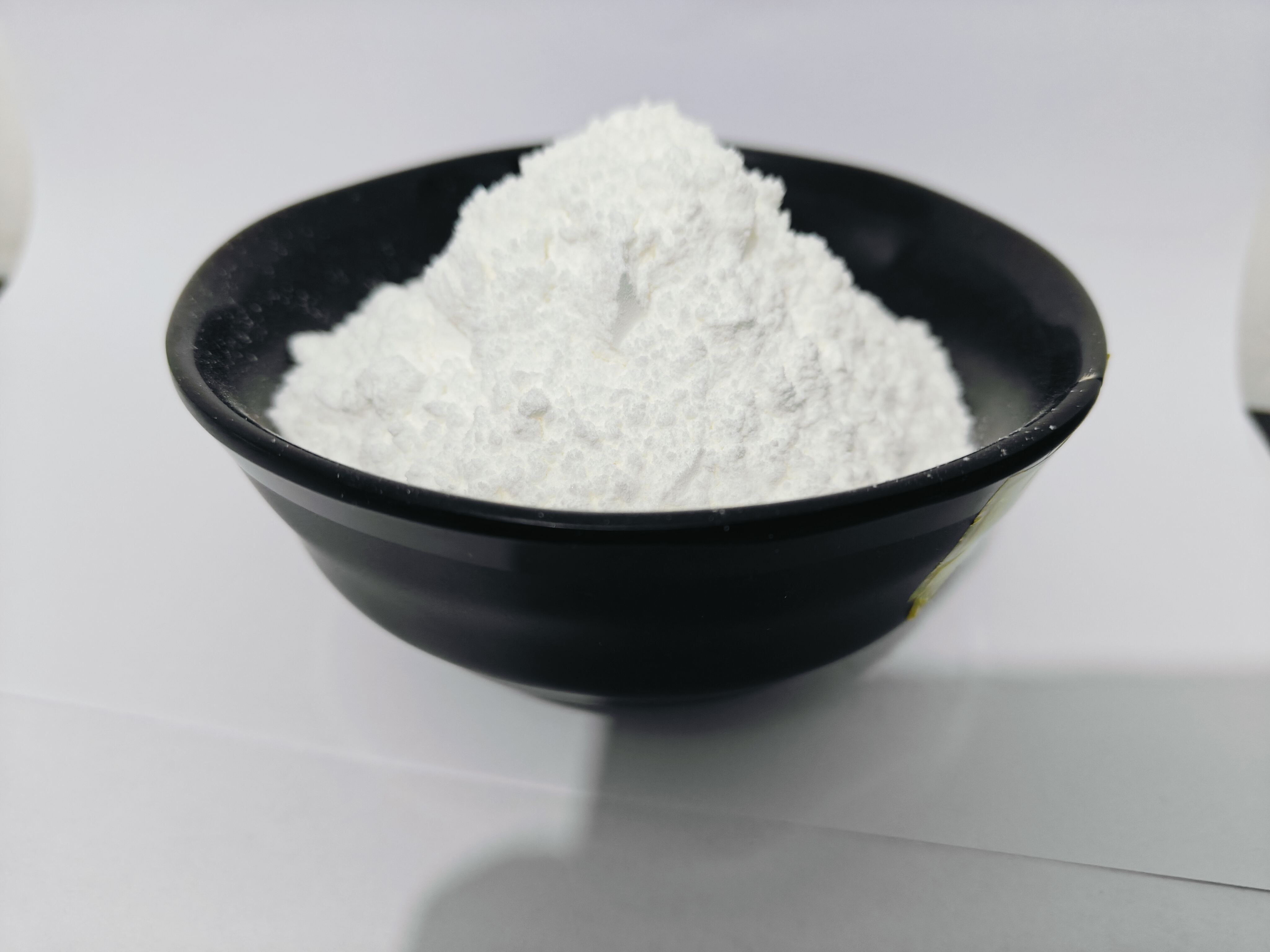

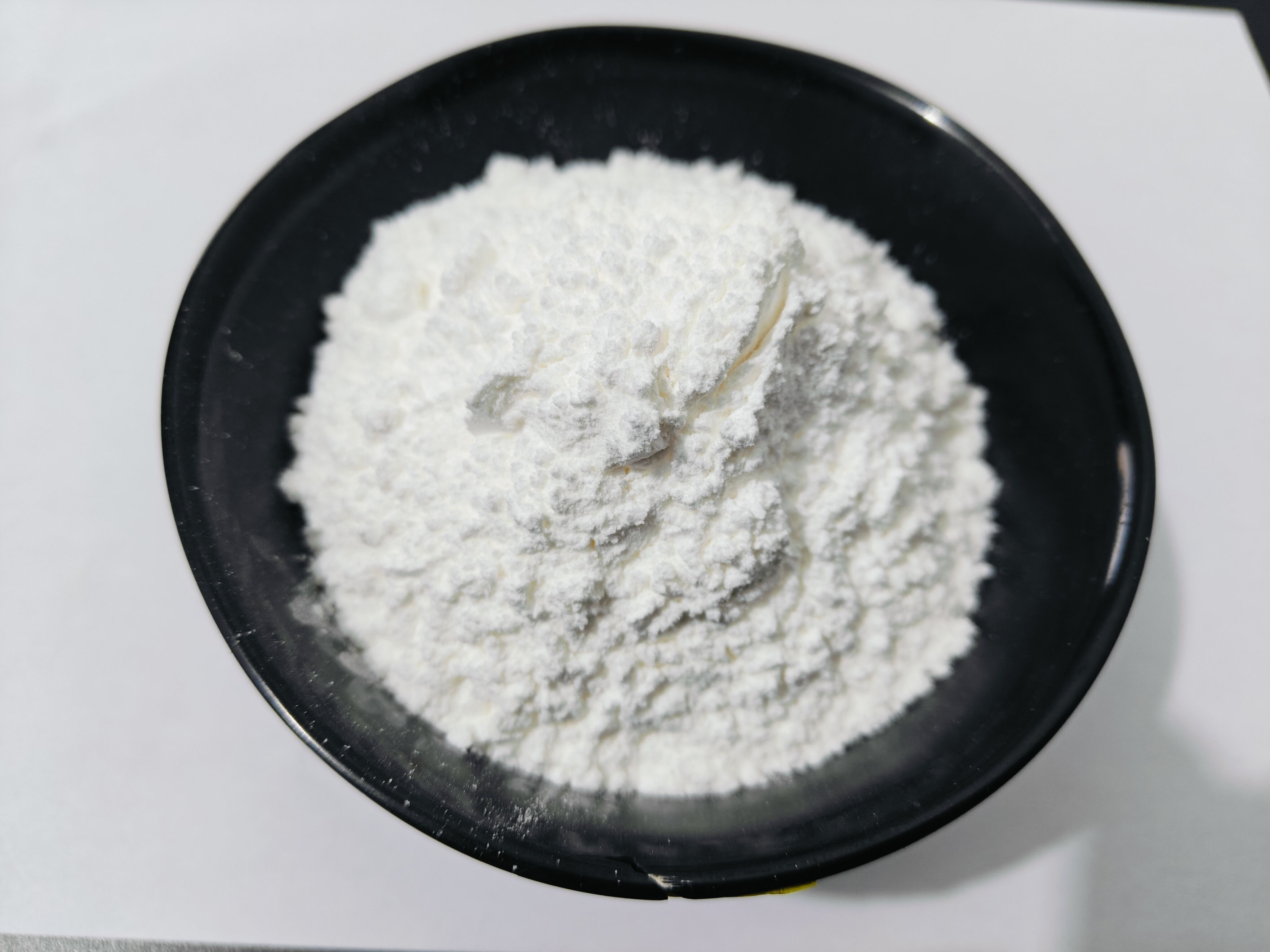

La viscosité de fusion pour le moulage par composés de moulage par époxy (EMC) est un paramètre essentiel qui détermine la qualité et l'efficacité des processus d'emballage électronique. Cette propriété mesure la résistance du composé de moulage à la coulée lorsqu'il est chauffé à sa température de moulage. La viscosité optimale de la fonte assure un bon remplissage de la cavité du moule, une encapsulation complète des composants électroniques et un emballage sans vide. Dans le moulage par électromagnétique, le matériau présente généralement un comportement rhéologique complexe, passant d'un état solide à un état fluide à des températures élevées. La viscosité de fusion doit être soigneusement contrôlée dans une plage spécifique, généralement comprise entre 20 et 200 Pascal-secondes, pour obtenir des conditions de moulage optimales. Les formulations EMC modernes intègrent des modificateurs de débit et des catalyseurs avancés pour maintenir une viscosité constante tout au long du processus de moulage, évitant ainsi des problèmes tels que le remplissage incomplet, le balayage des fils ou le déplacement des pagailles. La mesure et le contrôle de la viscosité de fusion sont essentiels pour assurer une production fiable de paquets électroniques, en particulier dans les applications nécessitant une grande précision et une grande durabilité, telles que l'électronique automobile, les semi-conducteurs de puissance et les circuits intégrés.