Revolutionizing Electronic Manufacturing Through Advanced Curing Solutions

The landscape of electronic manufacturing has witnessed remarkable transformations, particularly in the realm of EMC curing accelerator technology. As electronic devices become increasingly complex and miniaturized, the demand for more efficient and reliable curing processes has never been greater. Modern EMC curing accelerator technology represents a quantum leap forward in how we approach electronic packaging and protection, offering unprecedented control over curing processes while significantly reducing production time and energy consumption.

The evolution of EMC curing accelerator technology has been driven by the need to meet stringent performance requirements in the electronics industry. From automotive electronics to consumer devices, manufacturers are constantly seeking ways to enhance production efficiency without compromising quality. This technological advancement has become a cornerstone of modern electronic manufacturing, enabling faster production cycles while ensuring superior protection for sensitive electronic components.

Core Innovations in Modern EMC Curing Systems

Advanced Chemical Formulations

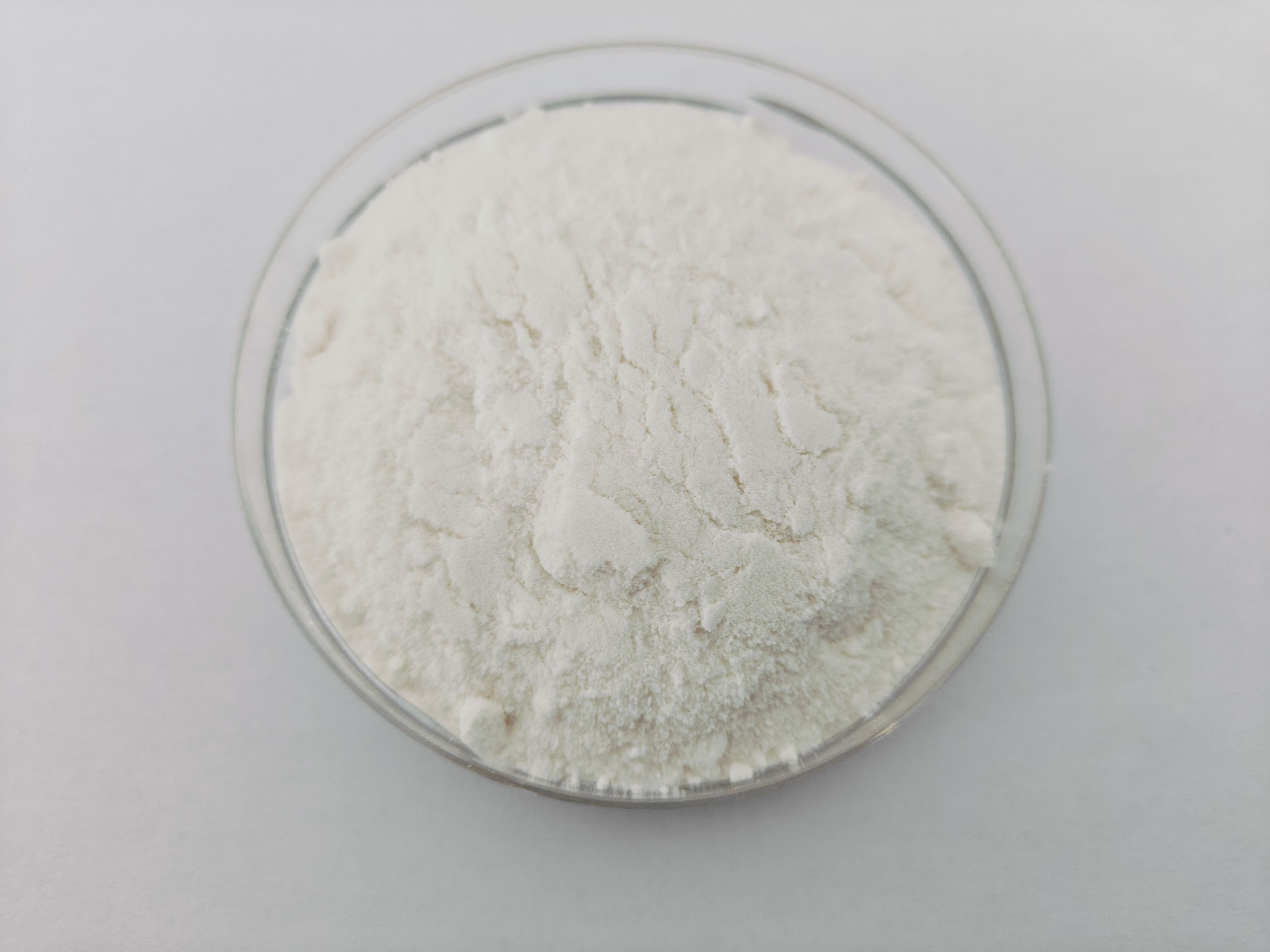

The latest EMC curing accelerator technology incorporates sophisticated chemical formulations that have revolutionized the curing process. These new formulations feature enhanced catalysts that activate at lower temperatures, allowing for more precise control over the curing reaction. The result is a more uniform curing process that ensures consistent quality across large production batches.

Moreover, these advanced formulations have been engineered to provide improved adhesion properties and reduced stress on electronic components during the curing process. This development has significantly decreased the likelihood of component failure and extended the overall lifespan of electronic devices.

Smart Temperature Control Systems

Modern EMC curing accelerator technology utilizes intelligent temperature control systems that optimize the curing process in real-time. These systems employ advanced sensors and algorithms to maintain precise temperature profiles throughout the curing cycle. This level of control ensures uniform heat distribution and prevents hot spots that could potentially damage sensitive components.

The integration of artificial intelligence and machine learning capabilities has further enhanced these systems, enabling them to adapt to varying environmental conditions and material properties automatically. This smart approach to temperature management has resulted in significant improvements in both product quality and energy efficiency.

Environmental and Efficiency Benefits

Sustainable Production Practices

Recent advances in EMC curing accelerator technology have placed a strong emphasis on environmental sustainability. New systems are designed to minimize energy consumption while maximizing throughput, resulting in a significantly reduced carbon footprint. The implementation of more efficient heating methods and improved insulation technologies has led to substantial energy savings across manufacturing facilities.

Additionally, modern curing accelerators incorporate eco-friendly materials and processes that comply with global environmental regulations. This focus on sustainability has not only benefited the environment but has also resulted in cost savings for manufacturers through reduced energy consumption and waste management.

Production Efficiency Optimization

The latest EMC curing accelerator technology has dramatically improved production efficiency through reduced cycle times and increased throughput. Advanced systems now feature multi-zone curing capabilities that allow for simultaneous processing of multiple components, significantly boosting production capacity.

Furthermore, automated quality control systems integrated into modern curing accelerators ensure consistent results while minimizing human intervention. This automation has led to reduced labor costs and improved product quality, making it easier for manufacturers to meet demanding production schedules.

Integration with Industry 4.0

Digital Connectivity and Control

Modern EMC curing accelerator technology seamlessly integrates with Industry 4.0 principles through advanced digital interfaces and connectivity options. These systems can now communicate with other production equipment and management systems, enabling real-time monitoring and control of the entire manufacturing process.

The implementation of IoT sensors and cloud-based monitoring systems allows manufacturers to collect and analyze vast amounts of data, leading to continuous process improvement and predictive maintenance capabilities. This level of connectivity ensures optimal performance and minimizes unexpected downtime.

Remote Monitoring and Management

The latest advances in EMC curing accelerator technology include sophisticated remote monitoring and management capabilities. Engineers can now monitor curing processes from anywhere in the world, making real-time adjustments as needed to maintain optimal performance. This capability has proven particularly valuable during recent global challenges that have limited on-site access to manufacturing facilities.

Remote diagnostics and troubleshooting features have also been enhanced, allowing technical support teams to quickly identify and resolve issues without the need for physical presence. This has resulted in improved uptime and reduced maintenance costs for manufacturing operations.

Future Trends and Developments

Emerging Technologies

The future of EMC curing accelerator technology shows promising developments in several key areas. Research is currently underway to develop even more energy-efficient systems that utilize alternative energy sources and novel heating methods. Additionally, work is being done to create more compact and flexible curing systems that can accommodate a wider range of component sizes and configurations.

Advancements in materials science are also driving innovation in EMC curing technology, with new compounds being developed that offer improved thermal conductivity and faster curing times. These developments are expected to further enhance the efficiency and effectiveness of curing processes in electronic manufacturing.

Industry Applications and Adaptations

As the electronics industry continues to evolve, EMC curing accelerator technology is being adapted to meet new challenges and requirements. The development of specialized curing solutions for emerging technologies such as flexible electronics and 3D-printed components is already underway. These adaptations will enable manufacturers to maintain high quality standards while working with increasingly complex and diverse electronic components.

The integration of EMC curing accelerator technology with advanced manufacturing processes is expected to continue, leading to even greater improvements in production efficiency and product quality. This ongoing evolution will play a crucial role in shaping the future of electronic manufacturing.

Frequently Asked Questions

How does EMC curing accelerator technology impact production costs?

EMC curing accelerator technology significantly reduces production costs through improved energy efficiency, faster curing times, and reduced waste. The initial investment in modern curing systems is typically offset by long-term savings in operational expenses and improved product quality.

What maintenance requirements are associated with modern EMC curing systems?

Modern EMC curing systems require regular calibration, cleaning, and preventive maintenance to ensure optimal performance. However, advanced diagnostic capabilities and predictive maintenance features have significantly reduced the frequency and duration of maintenance activities compared to older systems.

How does EMC curing accelerator technology ensure consistent quality across different batches?

Advanced EMC curing accelerator technology utilizes precise temperature control, automated monitoring systems, and sophisticated algorithms to maintain consistent curing conditions across all production batches. This ensures uniform quality and reliability in the final product, regardless of batch size or production timing.