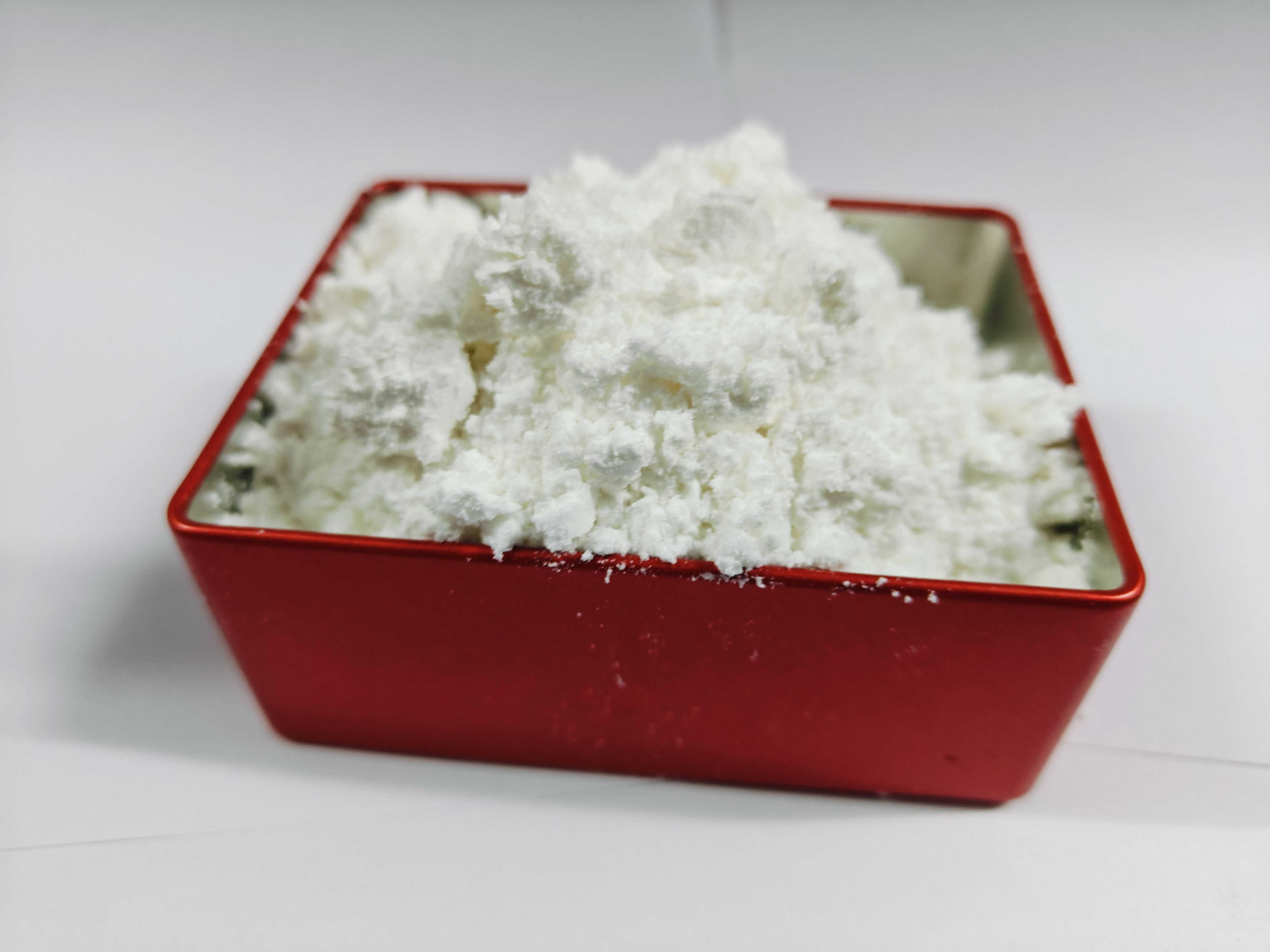

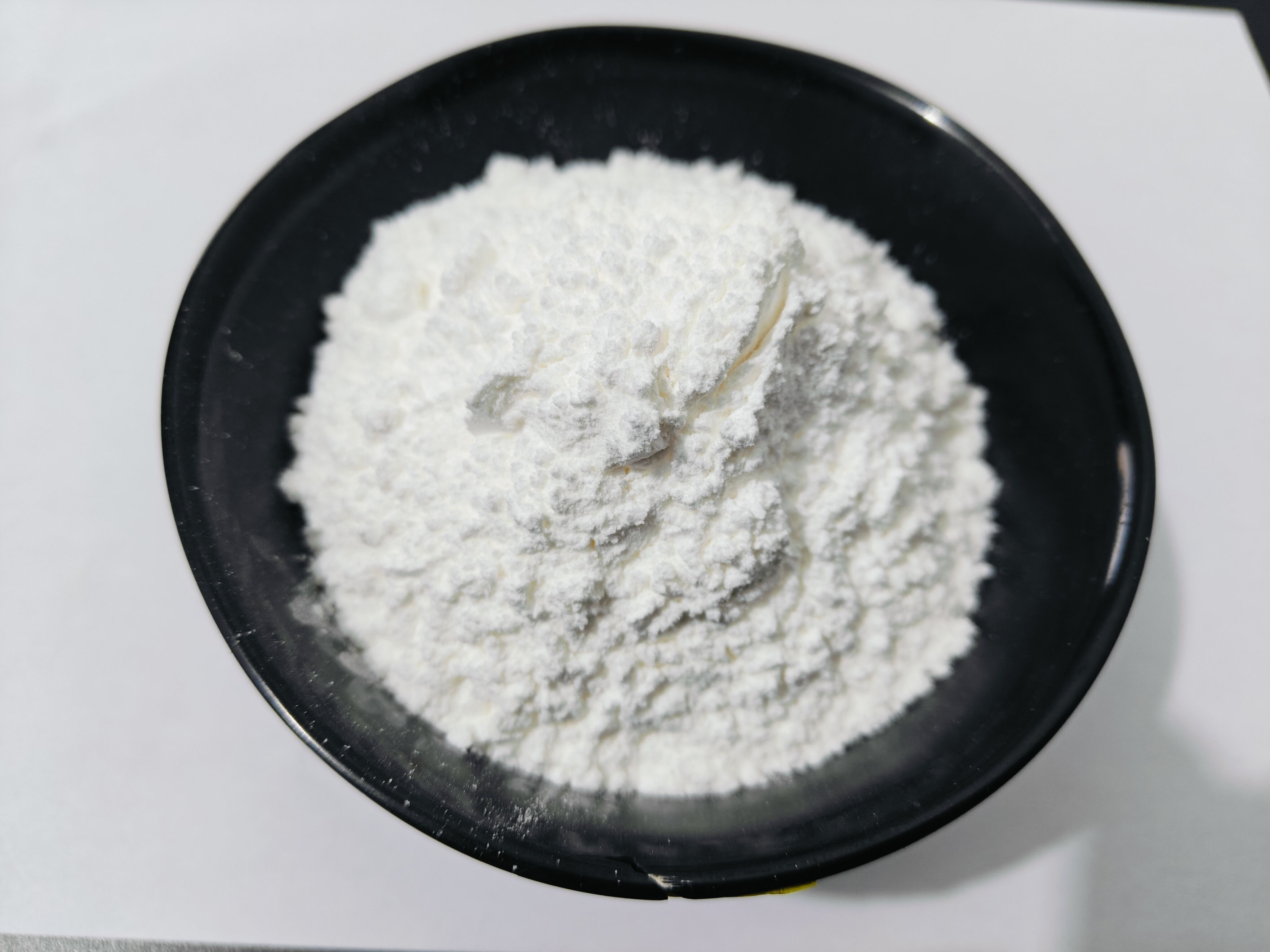

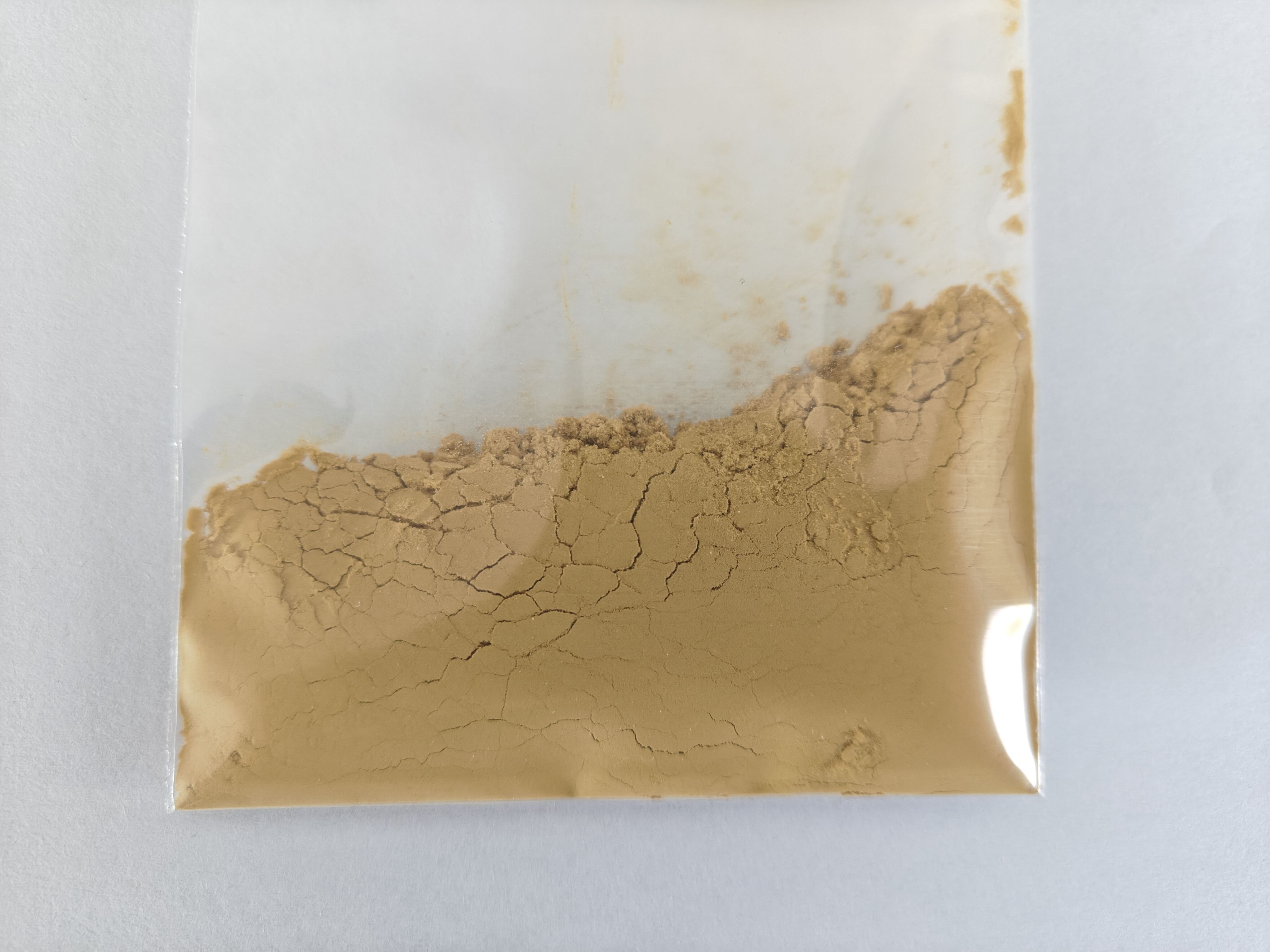

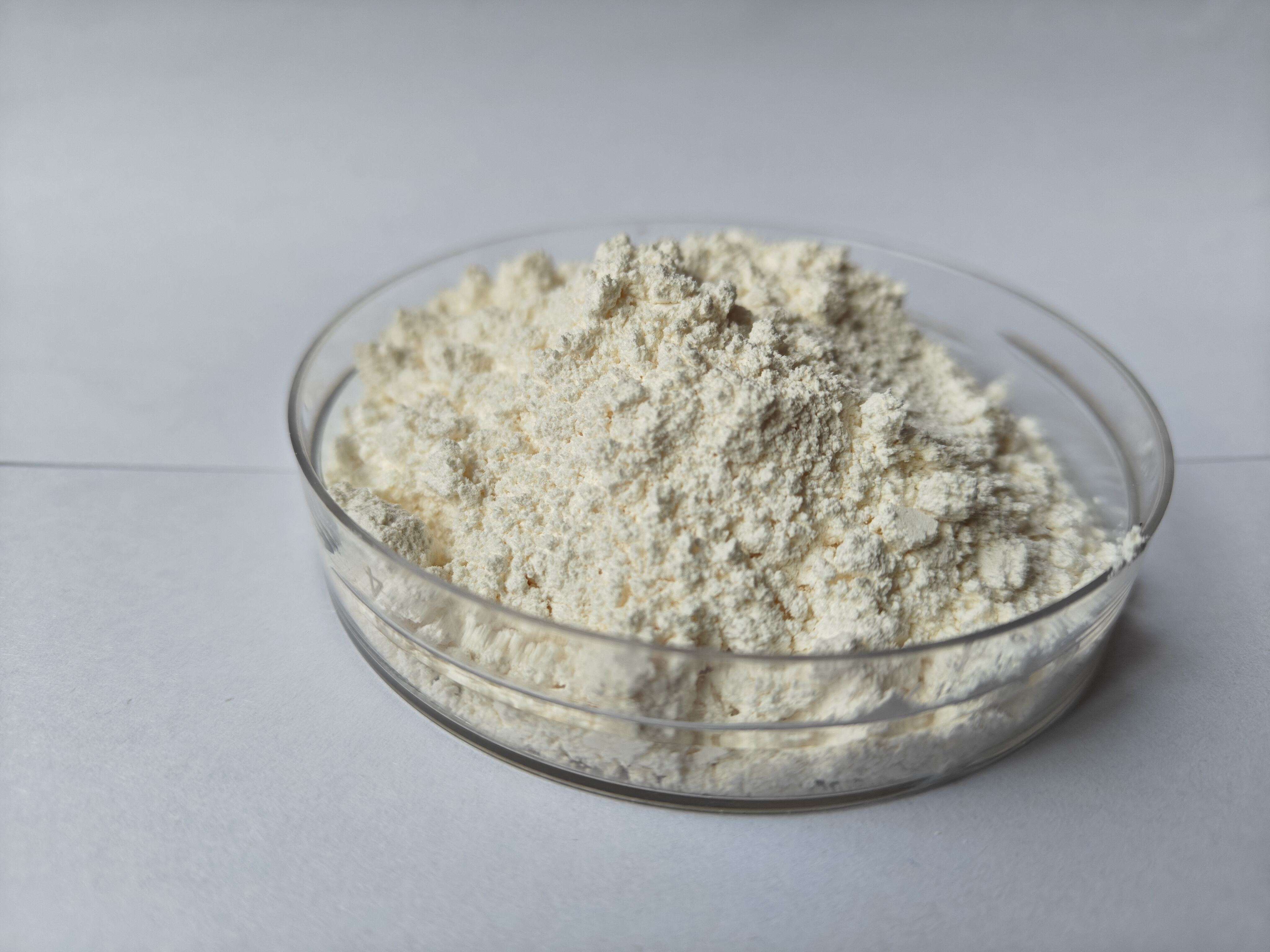

excellent epoxy molding compound

Excellent epoxy molding compound represents a cutting-edge solution in electronic packaging and protection technology. This advanced material combines superior mechanical strength, excellent thermal properties, and exceptional moisture resistance to provide comprehensive protection for electronic components. The compound is formulated using high-grade epoxy resins and specialized fillers, creating a versatile material that effectively encapsulates various electronic devices. Its primary functions include protecting sensitive electronic components from environmental factors, mechanical stress, and thermal variations. The compound's unique molecular structure ensures optimal adhesion to different substrate materials while maintaining dimensional stability across diverse operating conditions. In semiconductor packaging applications, it demonstrates remarkable flow characteristics during the molding process, enabling complete and void-free encapsulation of components. The material's advanced formulation also incorporates flame-retardant properties, meeting strict industry safety standards. With its excellent electrical insulation properties and enhanced thermal conductivity, the compound efficiently dissipates heat while maintaining reliable electrical performance. This versatile material finds extensive applications in automotive electronics, consumer devices, industrial controls, and advanced semiconductor packaging, where reliability and longevity are paramount.