epoxy molding compound suppliers in china

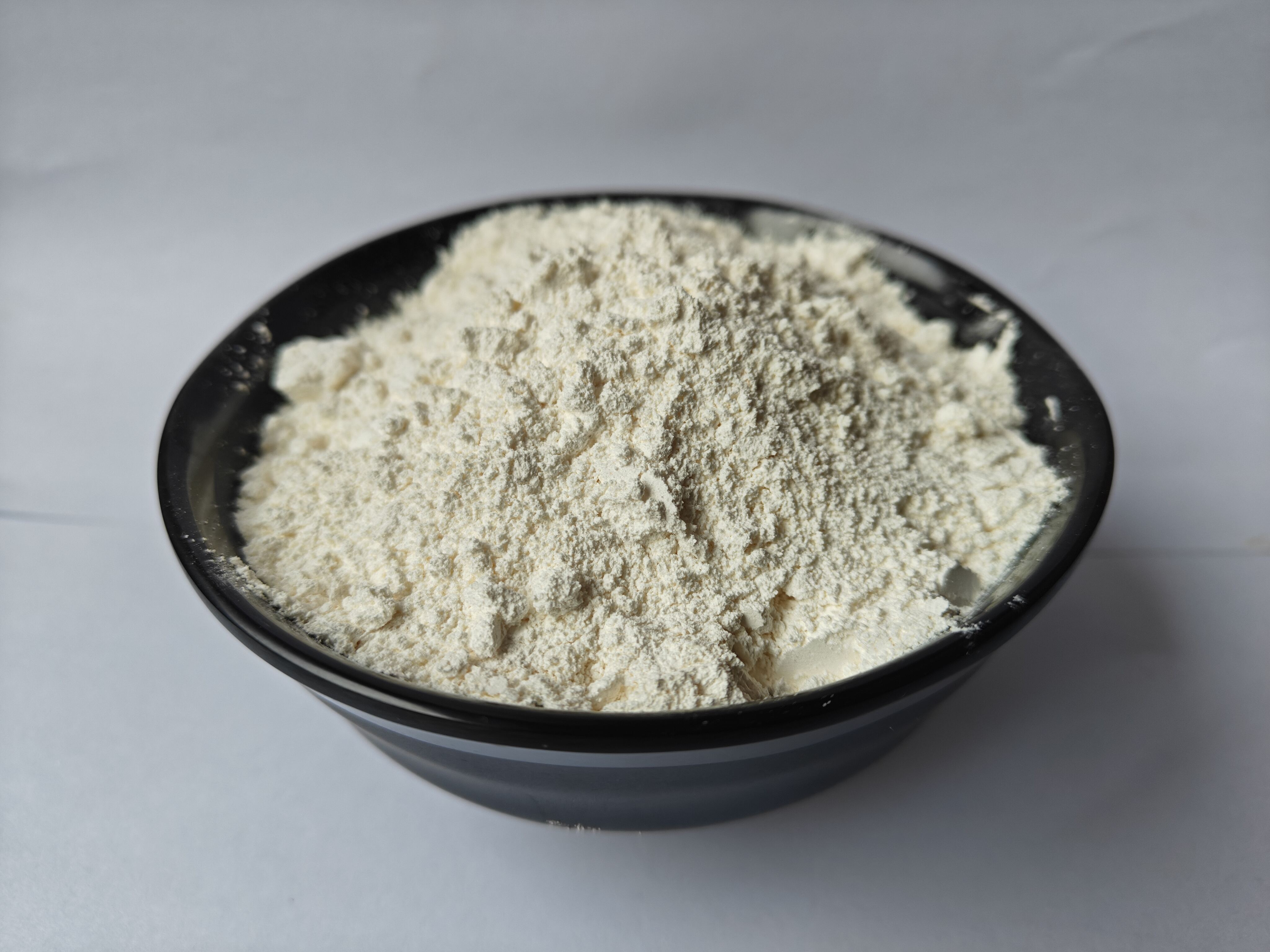

China's epoxy molding compound (EMC) suppliers represent a crucial segment in the global electronics manufacturing industry, offering high-quality encapsulation materials essential for protecting electronic components. These suppliers leverage advanced manufacturing facilities and stringent quality control processes to produce EMC that meets international standards. The compounds they produce feature excellent thermal stability, superior moisture resistance, and exceptional mechanical strength, making them ideal for various electronic applications. Chinese EMC suppliers typically offer a comprehensive range of products, including standard, halogen-free, and low-stress formulations. Their manufacturing capabilities encompass both traditional and cutting-edge molding technologies, enabling them to serve diverse industry needs. These suppliers have invested heavily in research and development, resulting in innovative formulations that address specific challenges in electronic packaging. The compounds they produce are widely used in semiconductor packaging, integrated circuits, automotive electronics, and consumer electronics. Many suppliers also provide customization options to meet specific customer requirements, from adjusting flow characteristics to modifying thermal properties.