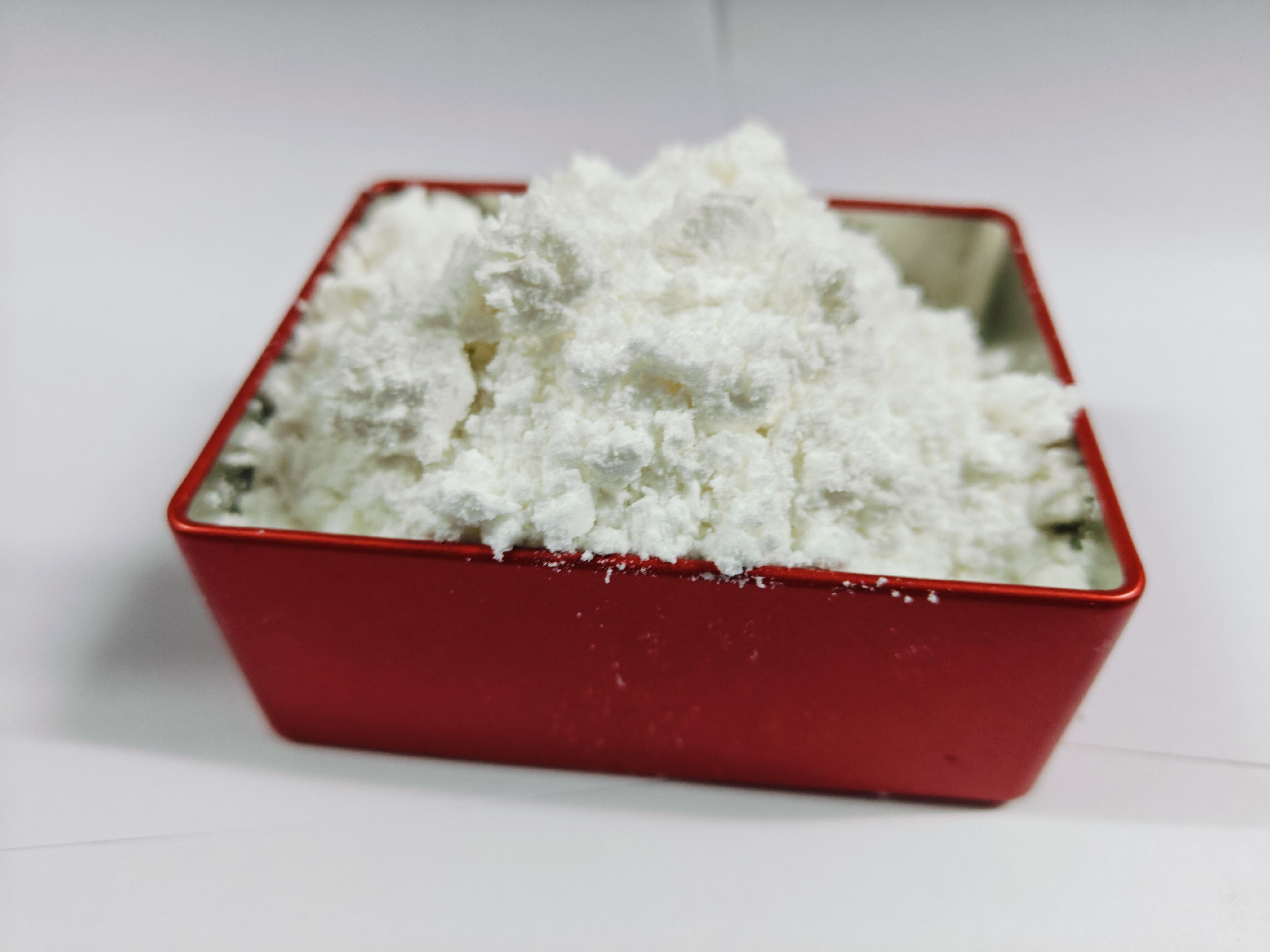

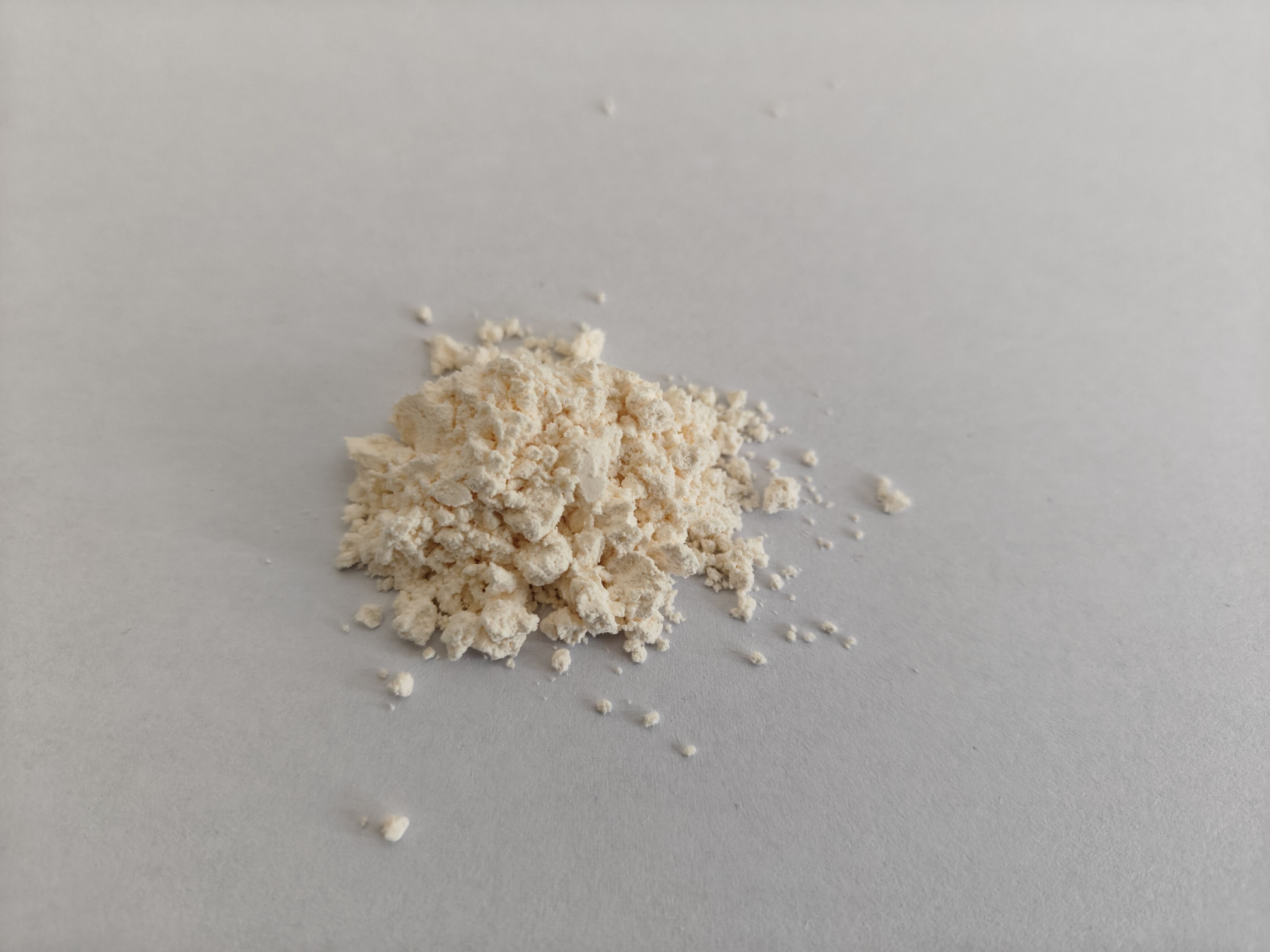

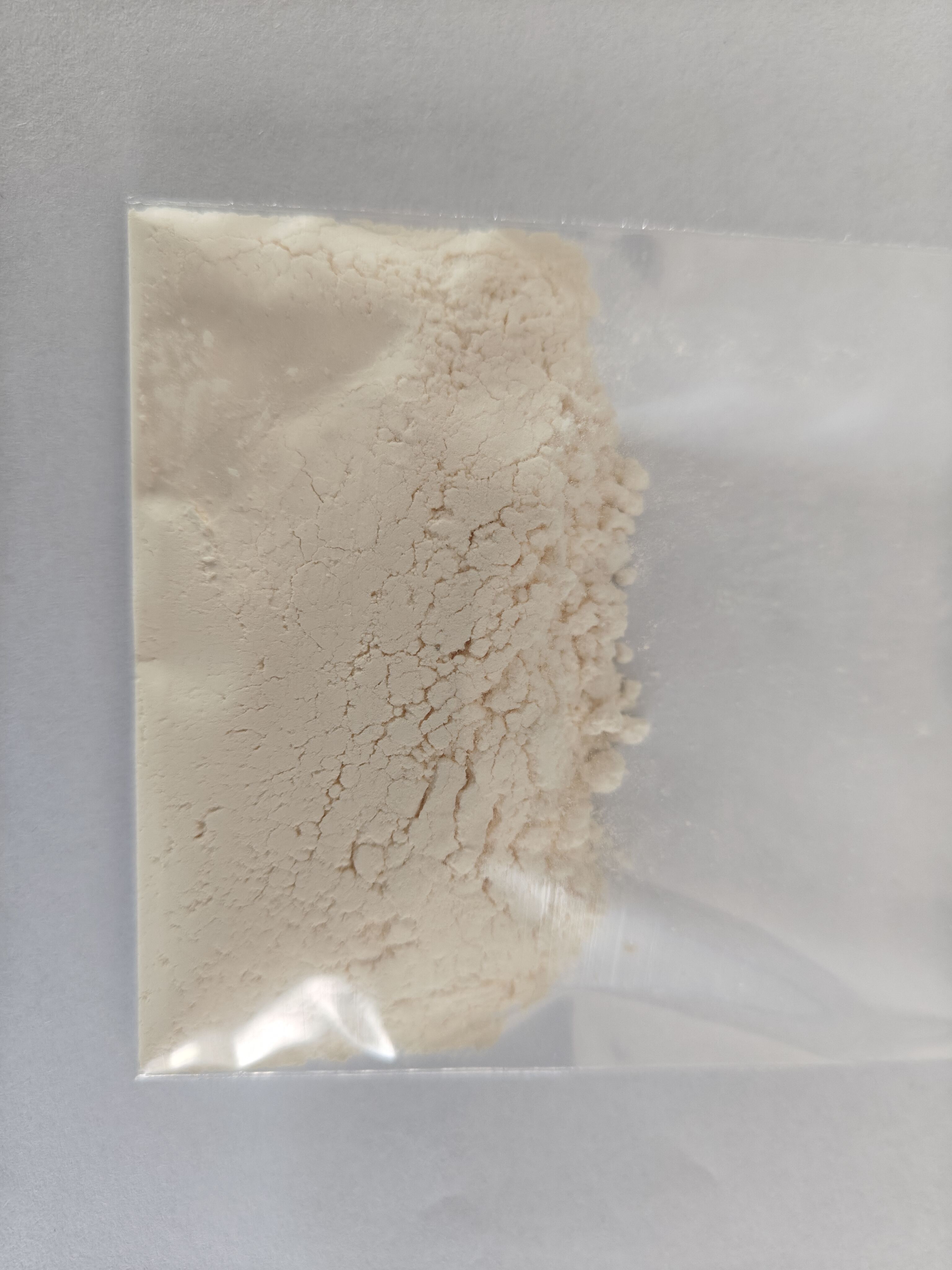

diversos aceleradores de cura

Os aceleradores de curagem são compostos químicos essenciais que melhoram e aceleram o processo de curagem de vários materiais, particularmente nas indústrias de polímeros e borracha. Estes aditivos especializados funcionam aumentando a taxa de reações de ligação cruzada, reduzindo significativamente o tempo e a energia necessários para a cura completa. Os aceleradores de cura modernos vêm em várias classificações, incluindo sulfenamidas, tiazoles, guanidinas e ditiocarbamato, cada um projetado para aplicações específicas e condições de cura. A tecnologia por trás desses aceleradores evoluiu para oferecer controle preciso sobre a cinética da cura, permitindo que os fabricantes otimizem a eficiência da produção mantendo a qualidade do produto. Em aplicações industriais, os aceleradores de curagem desempenham um papel crucial na fabricação de pneus, produtos de borracha, adesivos e selantes. Não só aceleram o processo de vulcanização, mas também contribuem para melhorar as propriedades físicas do produto final, tais como resistência à tração, resistência ao rasgo e características de envelhecimento. As formulações avançadas incorporam agora opções ecológicas que cumprem regulamentos ambientais rigorosos, proporcionando ao mesmo tempo um desempenho superior. Estes aceleradores são cuidadosamente concebidos para fornecer resultados consistentes em diferentes faixas de temperatura e condições de processamento, tornando-os inestimáveis nos processos de fabricação modernos.