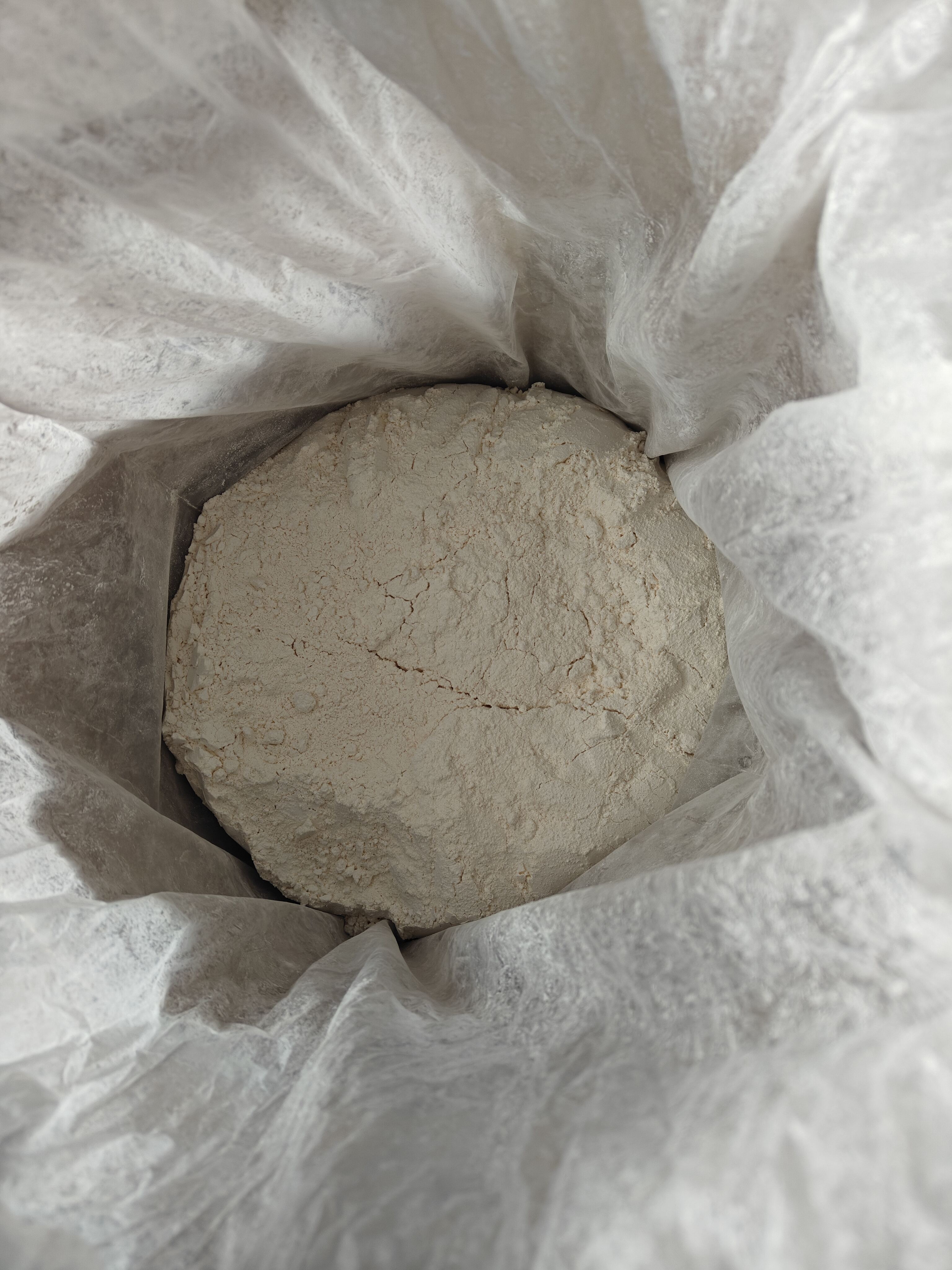

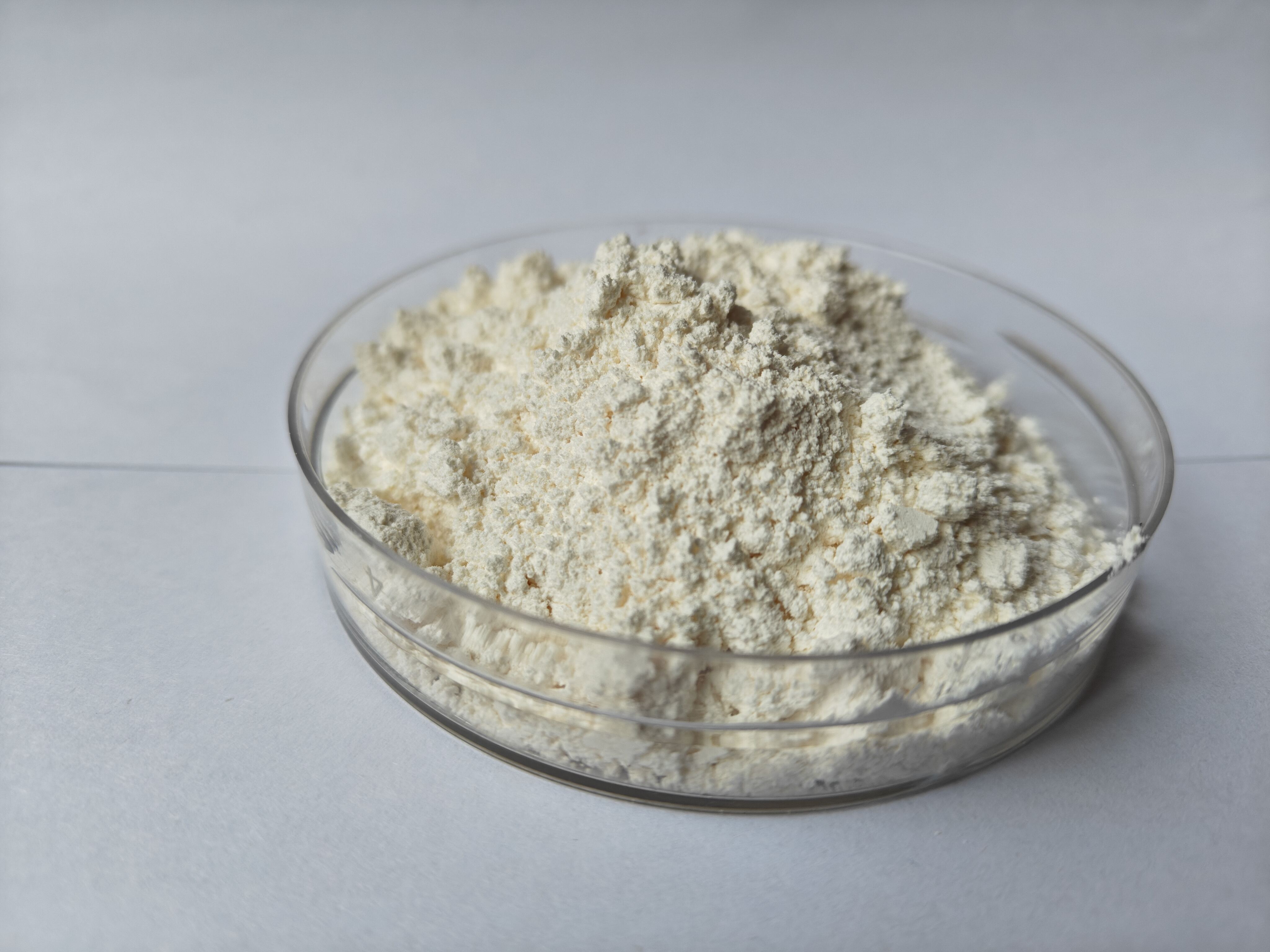

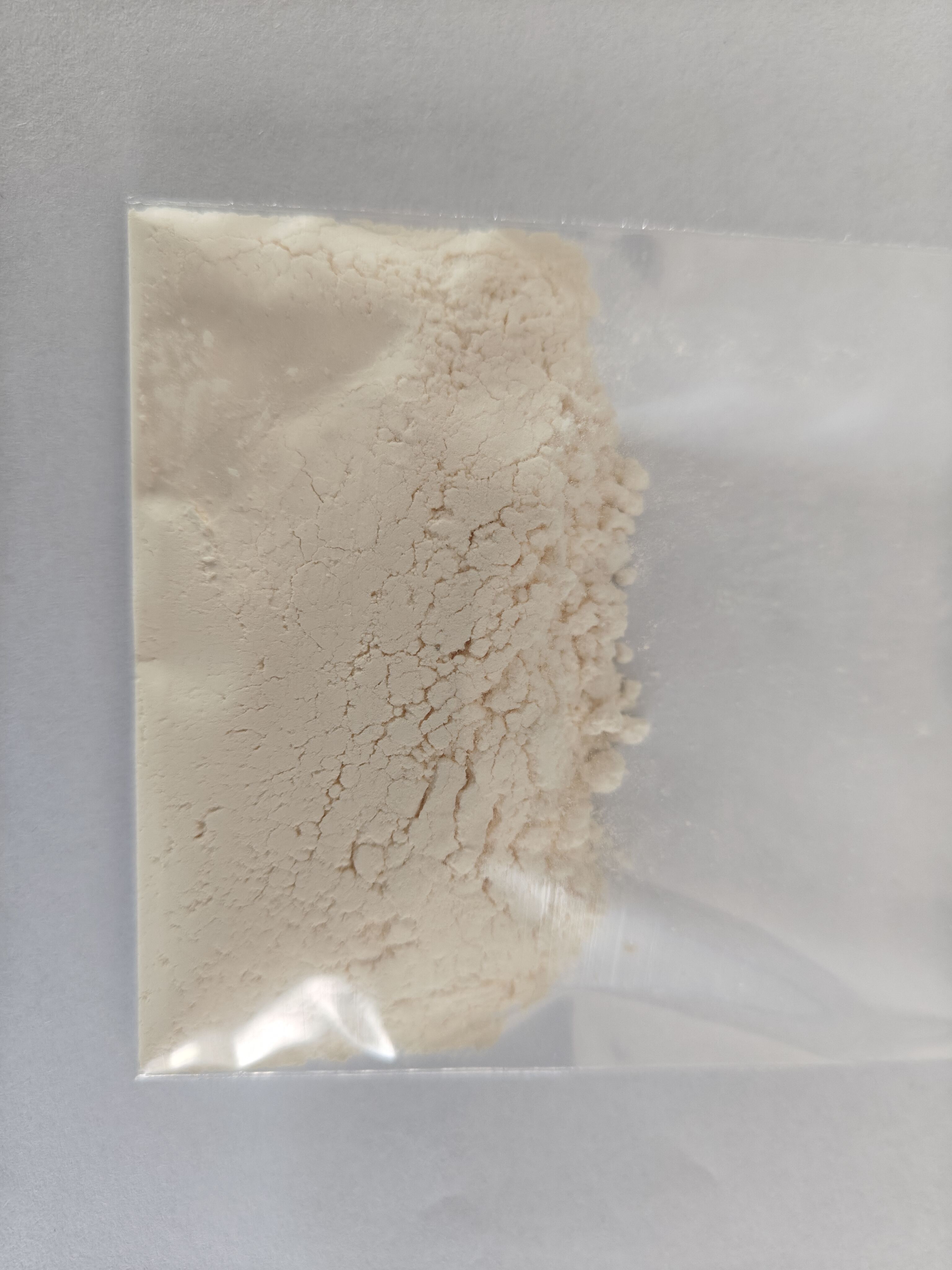

2p4mz catalysis in the curing of epoxy resins

2P4MZ catalysis plays a crucial role in the curing process of epoxy resins, representing a significant advancement in polymer chemistry. This heterocyclic compound, 2 phenyl 4 methylimidazole, functions as an effective catalyst that promotes the cross linking reaction in epoxy systems. The catalyst operates by initiating the polymerization process at relatively low temperatures, typically between 120 and 180 degrees Celsius, while ensuring a uniform and controlled curing rate. In industrial applications, 2P4MZ demonstrates exceptional stability during storage and provides predictable reaction kinetics, making it invaluable for manufacturing processes. The catalyst's molecular structure enables it to form strong coordination bonds with epoxy groups, facilitating the opening of epoxide rings and subsequent cross linking reactions. This mechanism results in enhanced mechanical properties, improved thermal stability, and superior chemical resistance in the final cured product. The technology finds extensive applications in electronic packaging, composite materials, adhesives, and protective coatings, where precise control over the curing process is essential for product performance.