nýr hlutdrægur hiti-latentur vinnslumaður

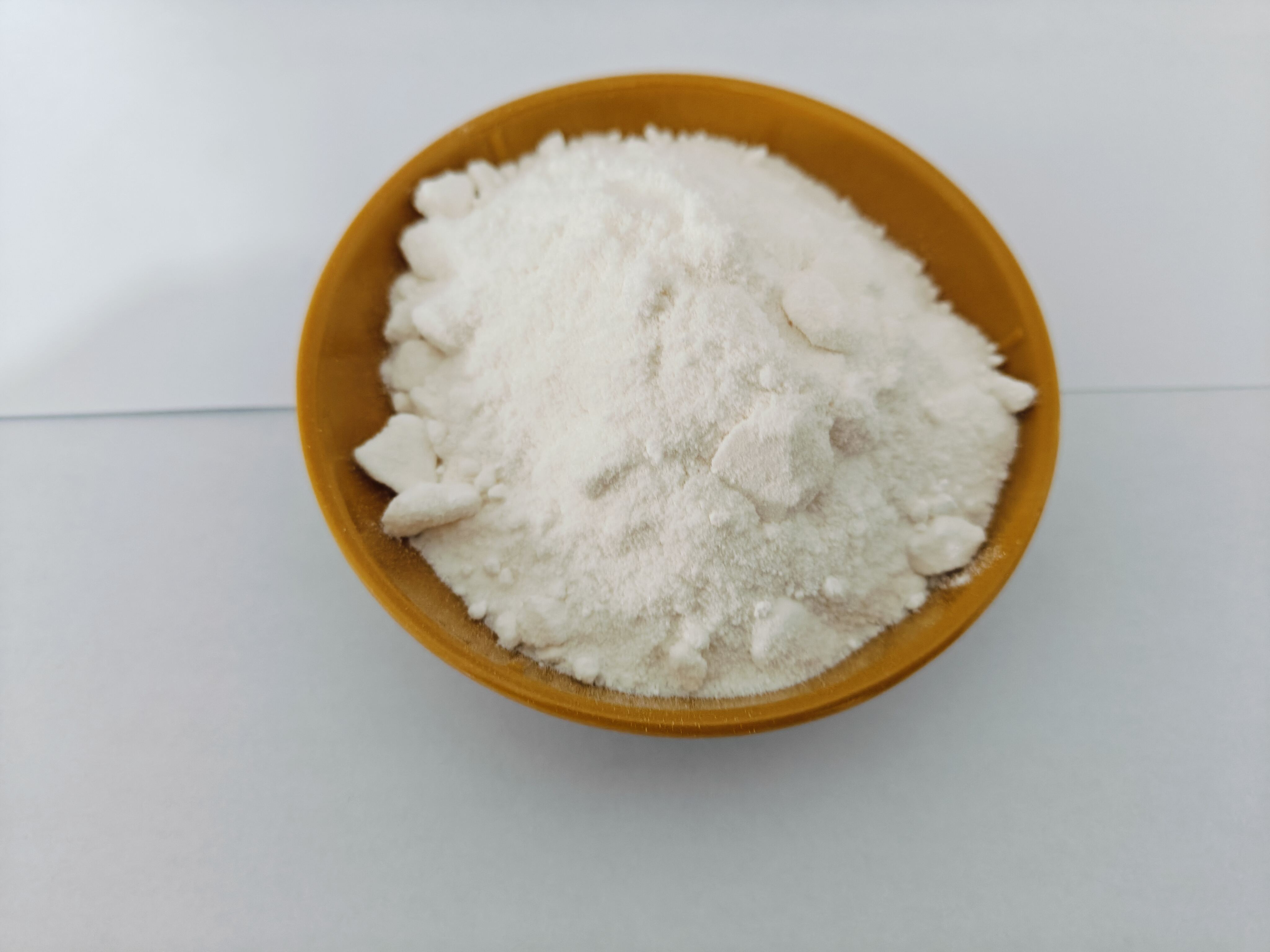

Nýtt og erfitt hlutverk sem virkar að latna er frábær nýsköpun í teknologi epoxyresánar, með möguleika á stjórnun afgangsferlið við ákveðin hitastig. Þessi nýsköpuð sameind hefur gagnrýni á hermælisstigi en virkar hratt þegar hún er komin í hárara hitu, gerandi mögulegt að stjórna afgangsferlinu nákvæmlega. Sameindin inniheldur frumvarplegt molekúlalíkan sem byggir á hitubrotum tengjum, sem brotna við ákveðin hitustig til að ræsa krísuhringssamskeytinguna. Þessi tegund gefur ósamanbærilega gagnrýni við vörumerki meðan hún heldur áfram hratt afgang þegar það er nauðsynlegt. Samskeypanarréttindi sameindarinnar leyfir lengra tíma í notkun við venjuleg gagnrýni, gerandi hana vel færð fyrir margföld af hverfisnotkun, þar á meðal skjaldeyri á bílum, elektronískar hluti og flugvélamaterial. Hennar fjölbreytileiki streitar aukinn við einn-og tvohlutakerfi, gefandi framleitendum fleksibilitu í samsetningu og notkunarmöguleikum. Nákvæmi hlutverksins sem virkar að latna með því að vera óvirkt þar til hiti virkar á það gerir það sérstaklega gagnlegt í notkunum sem krefja nákvæmrar tímariti og stjórnunar yfir afgangsferlið, eins og við samsetningu og límsamskeytingu þar sem fyrrverandi afgang verður að verða forðast.