ускорители за отвердване на емс

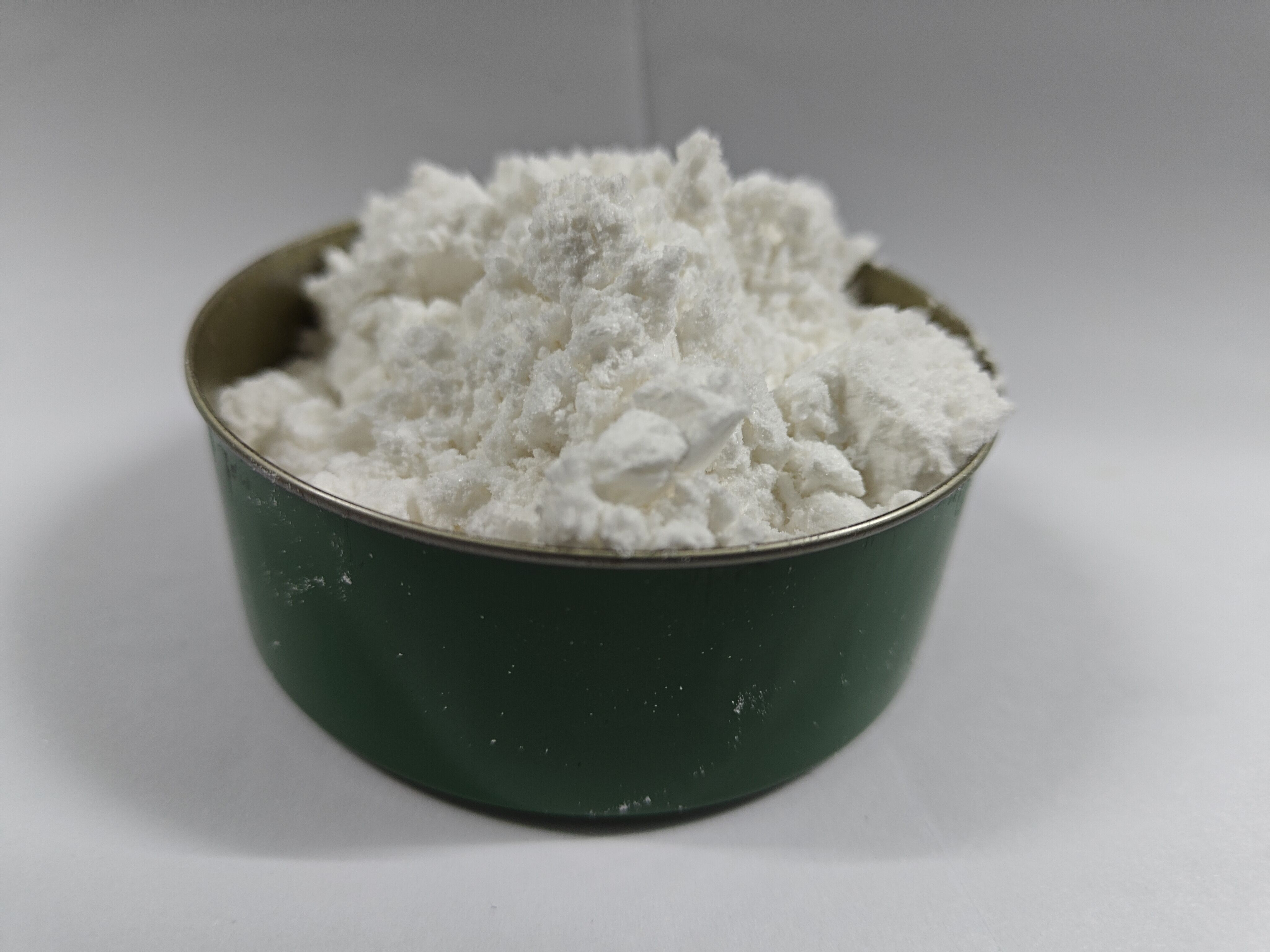

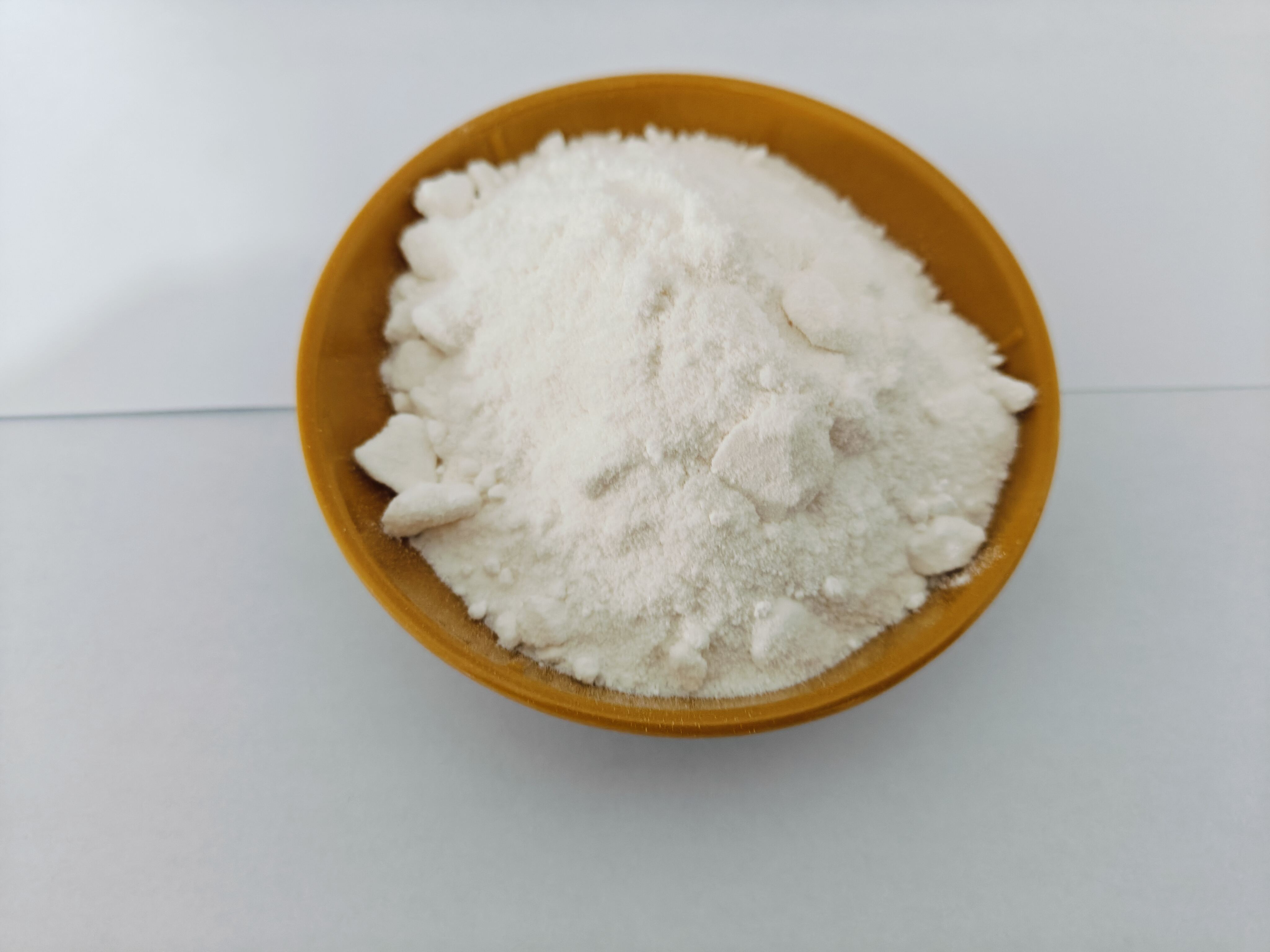

Ускорители за отвердаване на Епоксидни Молдингови Смеси (EMC) са основни добавки, които играят ключова роля в упаковката на полупроводници и производството на електронни компоненти. Тези специализирани химични състави са проектирани да подобряват процеса на отвердаване на епоксидните смоли, значително намалявайки времето за производство, като същевременно гарантират оптимални характеристики на производителността. Ускорителите работят чрез иницииране и контролиране на реакциите на кръстосване в епоксидната система, което води до по-бързи темпи на отвердаване при по-ниски температури. Прогресивните формули на ускорители за EMC предлагат точен контрол върху времето за загъстяване, скоростта на отвердаване и крайните свойства на измoldуваните компоненти. Те са специално разработени да поддържат стабилност по време на съхранение и обработка, докато осигуряват отлични характеристики на течност при процеса на moldуване. Тези ускорители са съвместими с различни пламеннозащитни агенти и други добавки, които често се използват в приложенията за електронна упаковка. Нивното прилагане води до подобрена производствена ефективност, намалено потребление на енергия и подобрено качество на крайните инкапсулирани електронни компоненти. Технологията зад тези ускорители продължава да се развива, отговаряйки на все повече изискванията на съвременните процеси за производство на електроника, включително нуждата за по-висока термична стабилност и по-добро съпротивляване на влажността.