nncarbonyldiimidazole factory

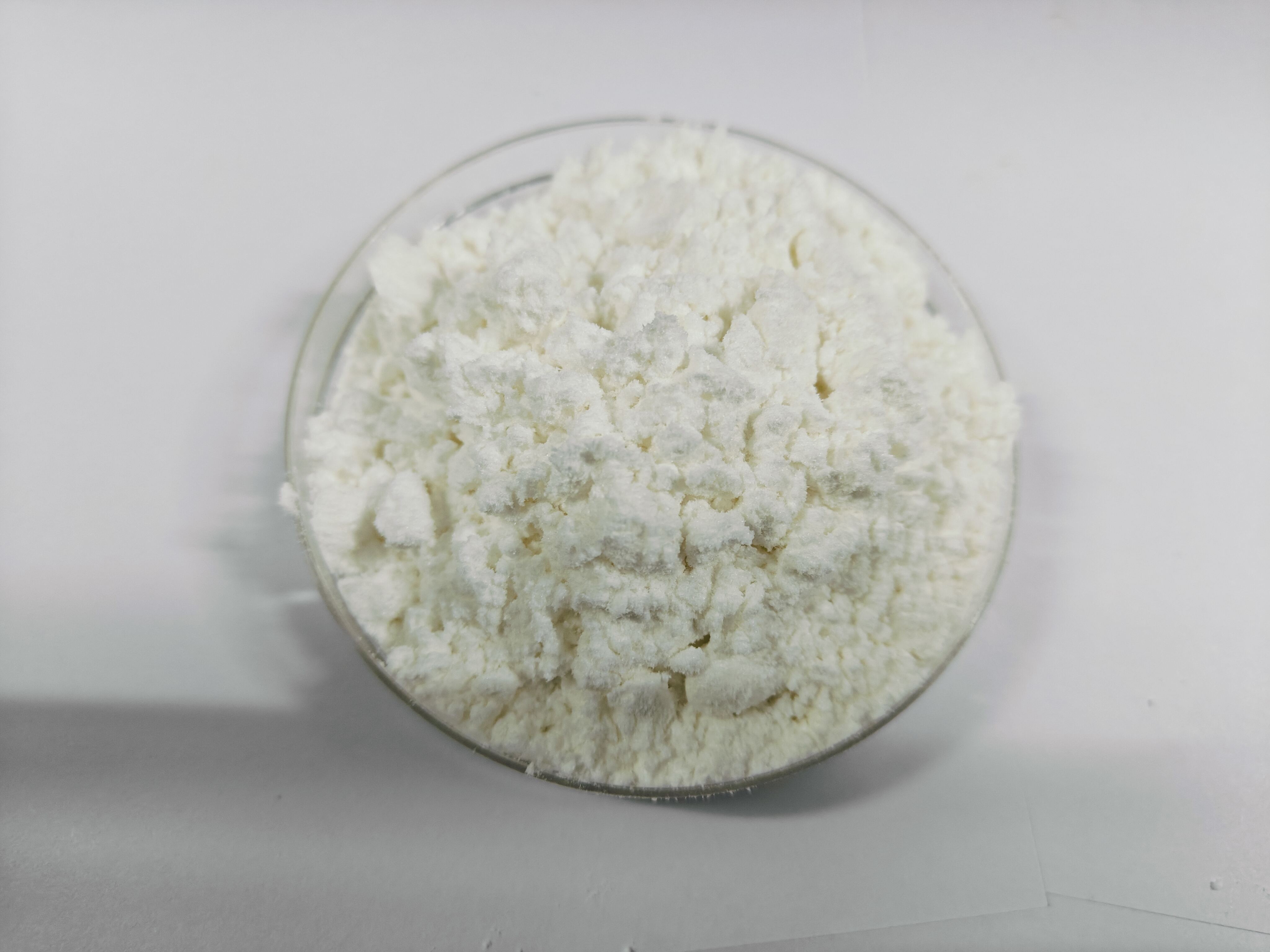

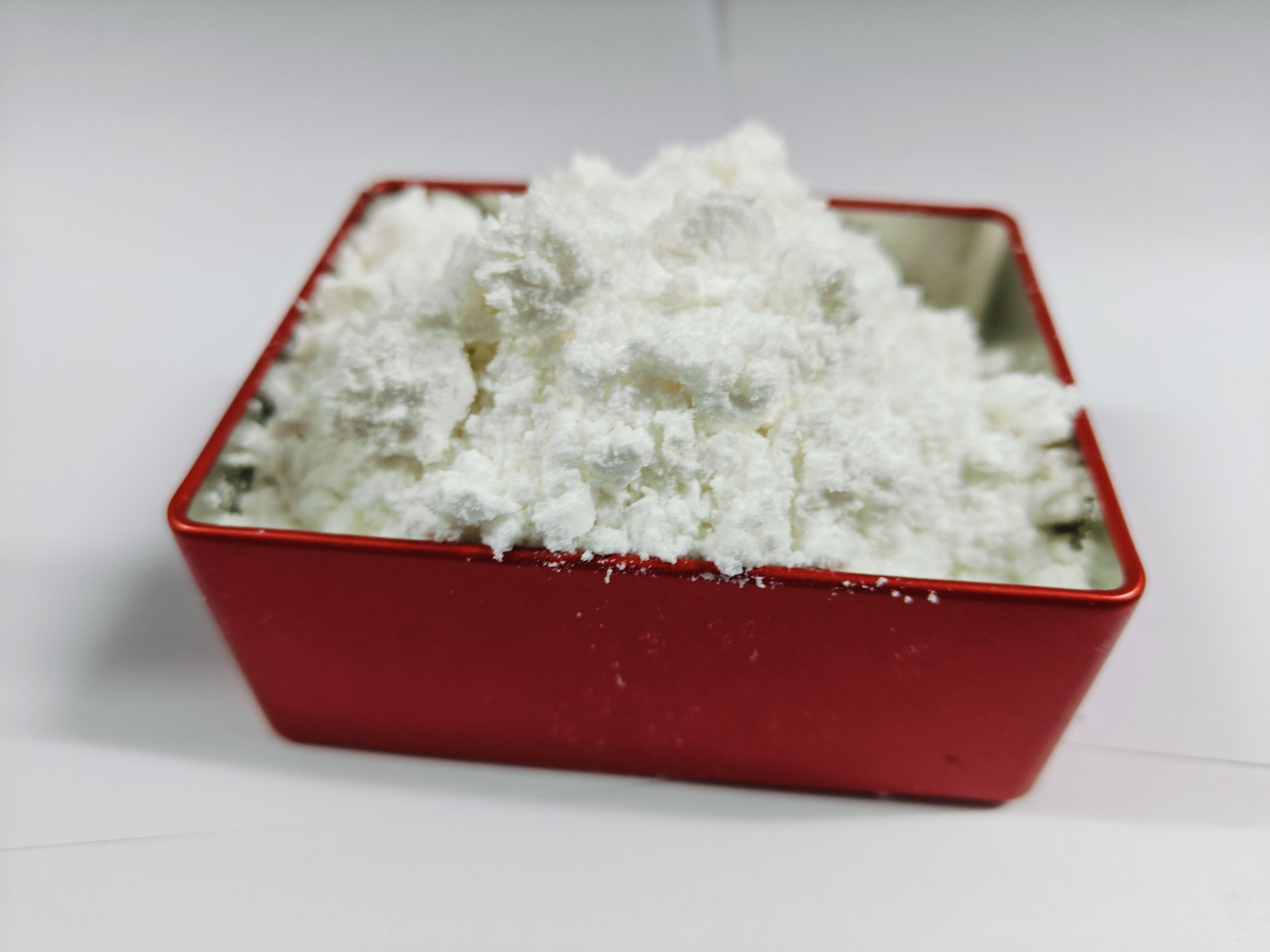

The N,N'-Carbonyldiimidazole (CDI) factory stands as a state-of-the-art manufacturing facility dedicated to producing high-quality CDI compounds essential for pharmaceutical and chemical industries. The facility incorporates advanced automation systems and precision control mechanisms to ensure consistent product quality and optimal production efficiency. Operating under strict GMP guidelines, the factory features multiple production lines equipped with cutting-edge reactors, crystallization units, and purification systems. The facility's design emphasizes environmental sustainability through closed-loop production processes and advanced waste treatment systems. With a production capacity of several hundred metric tons annually, the factory maintains dedicated quality control laboratories, automated packaging lines, and climate-controlled storage areas. The facility's infrastructure includes sophisticated analytical instruments for real-time monitoring and comprehensive product testing, ensuring each batch meets rigorous quality standards. Additionally, the factory implements smart manufacturing principles, utilizing IoT sensors and data analytics for predictive maintenance and process optimization.