Ensuring Stability and Safety in Reagent Storage

In synthetic organic chemistry, precision and reliability hinge upon the quality and integrity of reagents used. Among the most widely utilized are CDI coupling reagents, known for their versatility and effectiveness in peptide synthesis, esterification, and amide bond formation. These reagents are sensitive and highly reactive, requiring thoughtful storage and careful handling to preserve their activity and reduce potential hazards. For laboratories working with complex reaction pathways or large-scale processes, ensuring the proper treatment of CDI coupling reagents is fundamental to maintaining consistency, safety, and yield quality.

Understanding the Nature of CDI Coupling Reagents

What Are CDI Coupling Reagents and Why Are They Important?

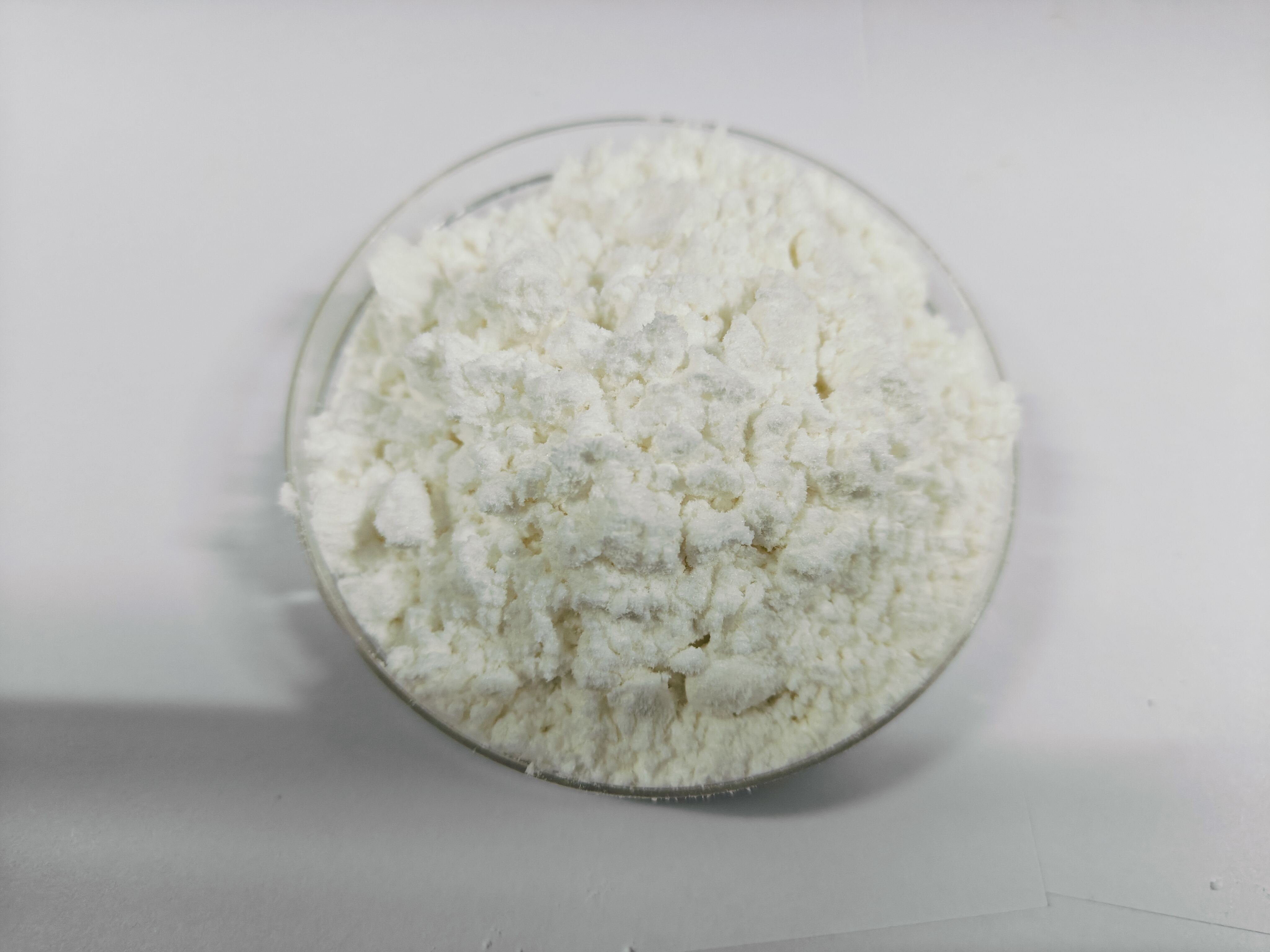

CDI coupling reagents, or carbonyldiimidazole compounds, serve as activating agents that facilitate the formation of amide and ester bonds. They are especially valuable in peptide synthesis, where coupling efficiency and selectivity are critical. Their high reactivity with carboxylic acids and alcohols makes them a preferred choice in many research and industrial settings. In addition to their effectiveness, CDI coupling reagents produce benign by-products, such as carbon dioxide and imidazole, simplifying the purification process. This makes them not only powerful but also practical for workflows requiring high throughput or automation.

Sensitivity and Reactivity Considerations

Due to their reactivity, CDI coupling reagents must be handled with a high degree of caution. These reagents are moisture-sensitive and can decompose rapidly if exposed to humidity or atmospheric water. Moreover, they may react violently with nucleophiles or bases under uncontrolled conditions, leading to side reactions or safety risks. Recognizing the reactive profile of CDI coupling reagents allows chemists to take proactive steps in preventing degradation or hazardous incidents. Special attention must be paid to environmental factors such as temperature, light exposure, and air contact to preserve their structural integrity.

Optimal Storage Guidelines

Temperature Control and Environmental Conditions

Maintaining a stable and appropriate temperature is vital for the longevity of CDI coupling reagents. Most manufacturers recommend storage at temperatures below 4°C or even in a deep freezer, depending on the specific formulation. Consistent refrigeration slows down potential decomposition and protects the reagent from unintentional thermal exposure. It's also crucial to avoid repeated freeze-thaw cycles, which can lead to moisture absorption or crystallization anomalies. In high-throughput labs, using temperature-controlled sample drawers or cold storage desiccators can be especially effective in preventing accidental reagent degradation.

Moisture Exclusion and Container Types

As CDI coupling reagents are hygroscopic, moisture control is a top priority. To mitigate moisture contamination, storage in airtight containers—preferably amber glass bottles with tightly sealing caps—is essential. Desiccants such as silica gel or molecular sieves can be placed inside storage cabinets or containers to further reduce humidity. After each use, bottles should be promptly resealed, and exposure to open air should be minimized. Utilizing gloveboxes or dry nitrogen glove bags is an advanced but highly effective method to handle these reagents without compromising stability. This not only extends shelf life but also ensures consistent reactivity during experiments.

Safe Handling Practices in Laboratory Settings

Personal Protective Equipment and Work Area Setup

When working with CDI coupling reagents, personal protective equipment (PPE) is non-negotiable. This includes chemical-resistant gloves, lab coats, and safety goggles. Some labs may require face shields or respiratory protection if operations involve large-scale quantities or potential aerosol generation. The workspace should be well-ventilated, ideally inside a fume hood. Benchtop surfaces must be clean, dry, and free from reactive residues to prevent unintentional cross-contamination. Moreover, designated tools and containers for CDI reagents should be labeled and not shared with other chemicals, maintaining a clear and safe laboratory protocol.

Weighing and Transferring Without Contamination

To avoid contamination and preserve purity, CDI coupling reagents should be weighed quickly and accurately using sealed balances or weighing boats in dry environments. Transferring the reagent into reaction vessels must also be done carefully. Using powder funnels or anti-static scoops can reduce loss or spillage. It is recommended to immediately cap the reagent container after dispensing and return it to its proper storage location. Pipetting or scooping directly from the primary storage bottle should be avoided; instead, aliquoting smaller working amounts can help reduce the frequency of exposure and degradation.

Managing CDI Coupling Reagents in Production Environments

Large-Scale Operations and Bulk Storage

In industrial and pilot-scale operations, the handling and storage of CDI coupling reagents demand higher levels of control. Bulk storage containers should be fitted with inert gas blankets to eliminate oxygen and moisture intrusion. Automated systems that transfer the reagent under sealed or dry conditions can further minimize risks and improve efficiency. Standard operating procedures (SOPs) must be detailed and include emergency response protocols, storage rotation schedules, and routine inspections to monitor for signs of degradation. For long-term use, regular sampling and analytical testing can confirm reagent potency, ensuring consistent performance in scaled-up reactions.

Waste Disposal and Spill Management

Spills involving CDI coupling reagents must be handled promptly and with full awareness of their reactive potential. Small spills should be contained with dry, inert absorbents like vermiculite or sand. Water should never be used, as it can lead to violent reactions. Disposal should follow local regulatory guidelines and involve proper labeling and containment of both solid and liquid waste forms. Unused or expired CDI reagents should be treated as hazardous chemical waste and disposed of via certified waste management services. Regular training of lab personnel on spill response and disposal procedures is a proactive strategy to minimize environmental impact and safety incidents.

Enhancing Workflow and Productivity with Stability in Mind

Best Practices for Inventory Management

Managing your stock of CDI coupling reagents efficiently helps reduce waste and optimize usage. Implementing a first-in, first-out (FIFO) system ensures older reagents are used before newer ones, preventing unnecessary degradation. All containers should be clearly labeled with the date of receipt and first opening, along with expiration dates if provided. Digital inventory tracking systems can automate this process and alert users when reagents are approaching their recommended shelf life. Maintaining logs of usage patterns also aids in future procurement planning, helping labs maintain just-in-time inventory levels without compromising operational continuity.

Supplier Communication and Quality Verification

Working with reputable suppliers of CDI coupling reagents ensures that you are receiving high-purity, well-packaged, and stable products. Before procurement, reviewing the certificate of analysis (CoA), MSDS sheets, and packaging specifications provides insight into the product’s quality standards. Some suppliers also offer customized packaging sizes and inert gas-filled containers for added stability. Open communication with suppliers regarding shipping conditions—especially for temperature-sensitive batches—can prevent damage during transit. Ensuring your supplier shares your commitment to quality and safety greatly reduces the likelihood of receiving compromised reagents.

Training and Documentation as a Safety Net

Standard Operating Procedures and Protocol Documentation

A well-documented SOP is the backbone of consistent laboratory practices involving CDI coupling reagents. This document should detail storage temperatures, handling steps, required PPE, reaction protocols, and waste disposal instructions. All lab personnel must be trained in these procedures and regularly updated on any revisions. In regulated environments, these SOPs may also serve compliance purposes for audits or inspections. Proper documentation not only ensures safety but also improves reproducibility of experiments and reduces human error across research or manufacturing workflows.

Lab Training and Continuous Improvement

Training is a continuous process. All personnel working with CDI coupling reagents should undergo initial onboarding followed by periodic refresher courses that reinforce safety, handling, and best practices. Simulated emergency drills, real-time troubleshooting scenarios, and hands-on demos can enhance understanding and readiness. Feedback loops should be built into the training programs, allowing users to suggest improvements or report inconsistencies. Encouraging a safety-first culture where best practices are not only followed but actively refined leads to safer and more effective reagent management.

FAQ

How should CDI coupling reagents be stored for long-term stability?

CDI coupling reagents should be stored in airtight containers under refrigeration, ideally below 4°C, and protected from moisture using desiccants or inert gas environments. Avoid repeated freeze-thaw cycles to maintain purity.

What precautions should I take when handling CDI coupling reagents?

Wear proper PPE including gloves, goggles, and lab coats. Handle reagents in a dry, ventilated area, preferably in a fume hood. Minimize exposure to air and moisture during weighing and transfer processes.

Can CDI coupling reagents be used after their expiration date?

While some may retain reactivity, it's best to conduct a small-scale test or verify with analytical methods before using expired reagents. For critical applications, using fresh, verified material is recommended.

What should I do in case of a CDI reagent spill?

Isolate the spill area, avoid using water, and absorb with dry inert material. Dispose of the waste following hazardous chemical guidelines. Always refer to the reagent’s MSDS for specific emergency instructions.

Table of Contents

- Ensuring Stability and Safety in Reagent Storage

- Understanding the Nature of CDI Coupling Reagents

- Optimal Storage Guidelines

- Safe Handling Practices in Laboratory Settings

- Managing CDI Coupling Reagents in Production Environments

- Enhancing Workflow and Productivity with Stability in Mind

- Training and Documentation as a Safety Net

- FAQ