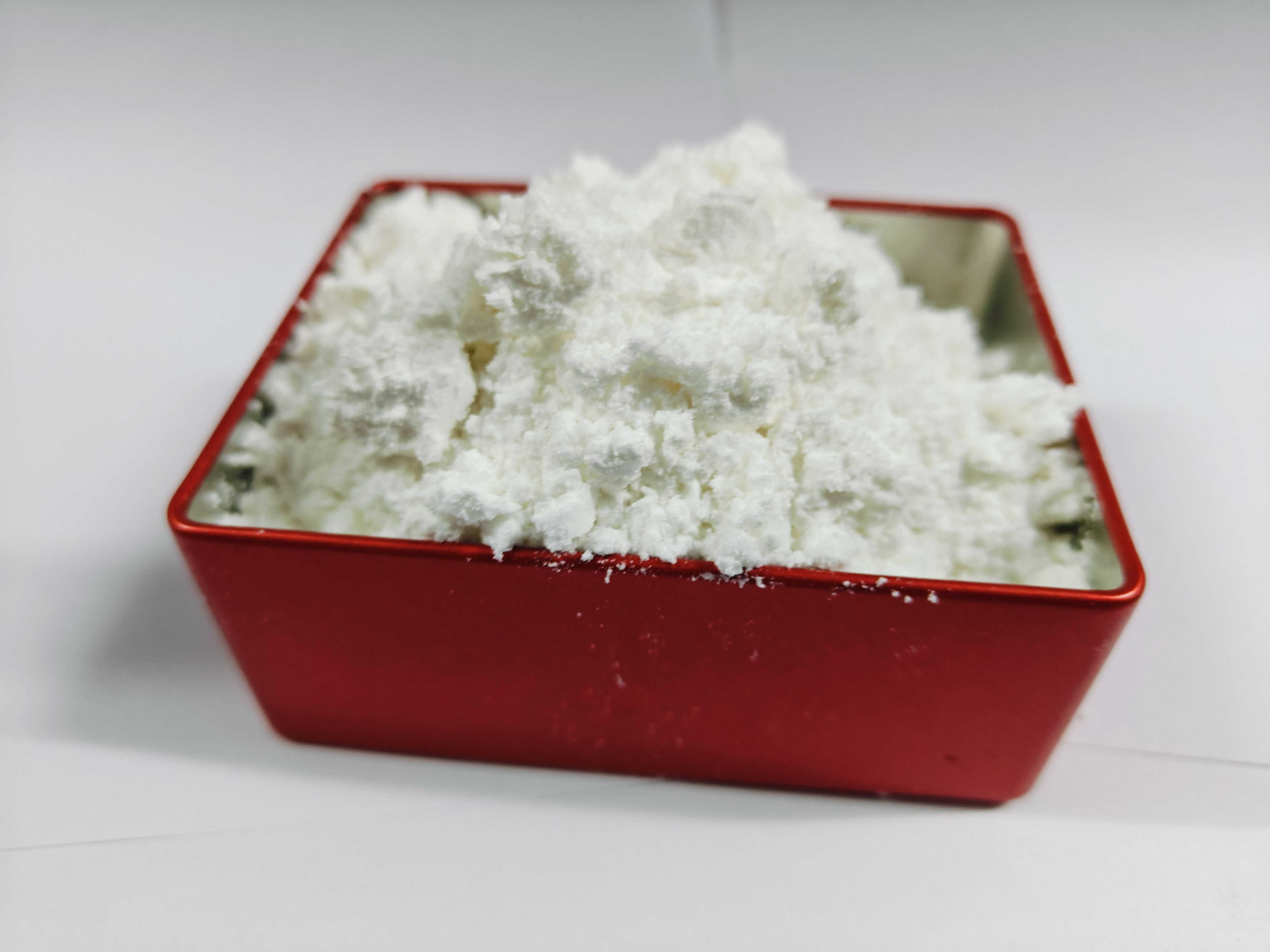

high performance epoxy curing agents

High performance epoxy curing agents are essential components in advanced epoxy systems, playing a crucial role in transforming liquid epoxy resins into durable, cross-linked polymer networks. These specialized chemical compounds initiate and control the curing process, determining the final properties of the epoxy system. They are engineered to provide superior mechanical strength, chemical resistance, and thermal stability compared to conventional curing agents. The technology behind these agents involves carefully designed molecular structures that optimize cross-linking density and reaction kinetics. They typically operate through amine, anhydride, or catalytic curing mechanisms, each offering distinct advantages for specific applications. In industrial applications, these curing agents are vital in aerospace composites, automotive components, protective coatings, and high-performance adhesives. They enable the formation of robust polymer networks that maintain their structural integrity under extreme conditions, including high temperatures, chemical exposure, and mechanical stress. The versatility of high performance epoxy curing agents allows for customization of cure schedules, working life, and final properties to meet specific application requirements.