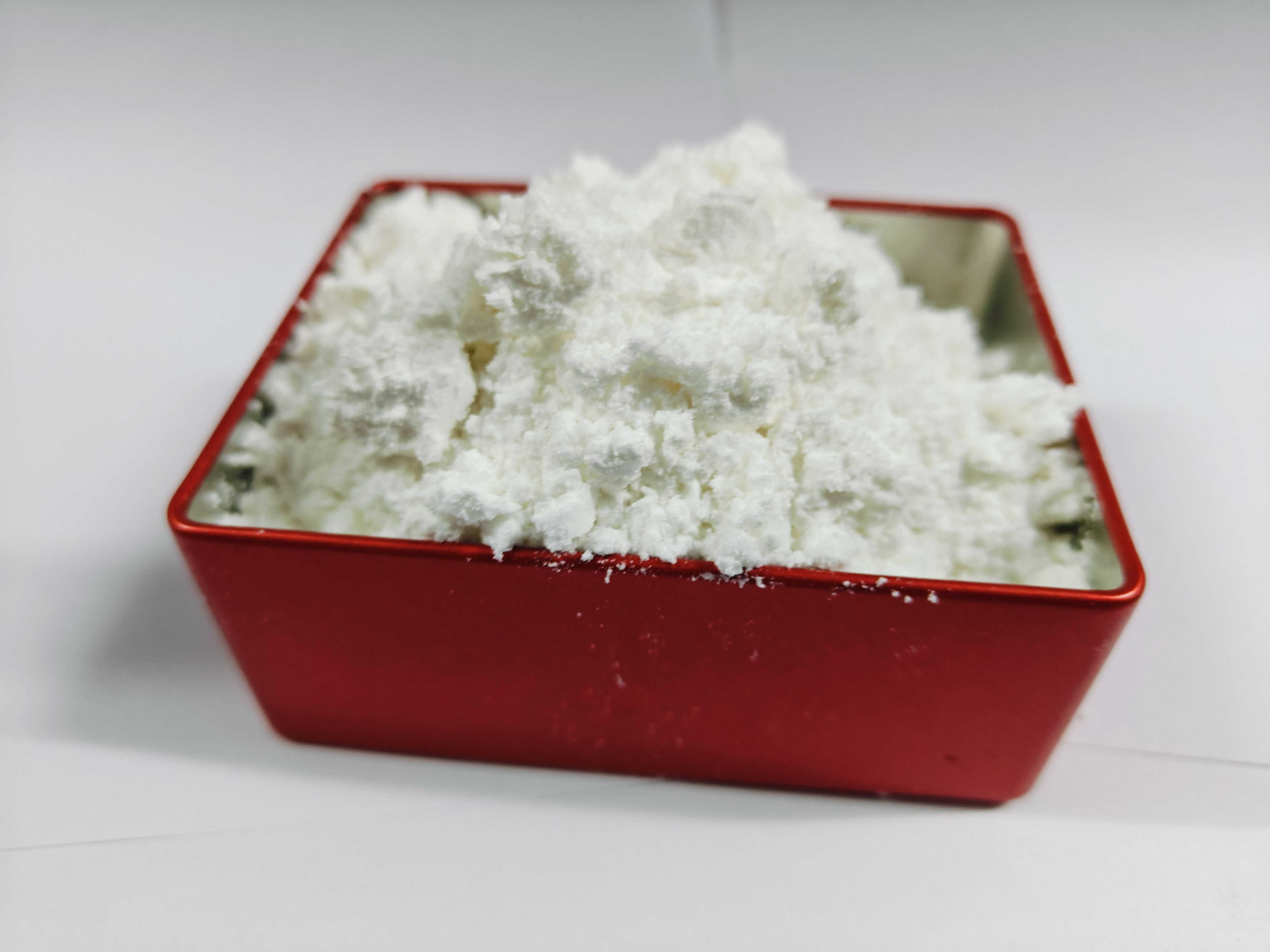

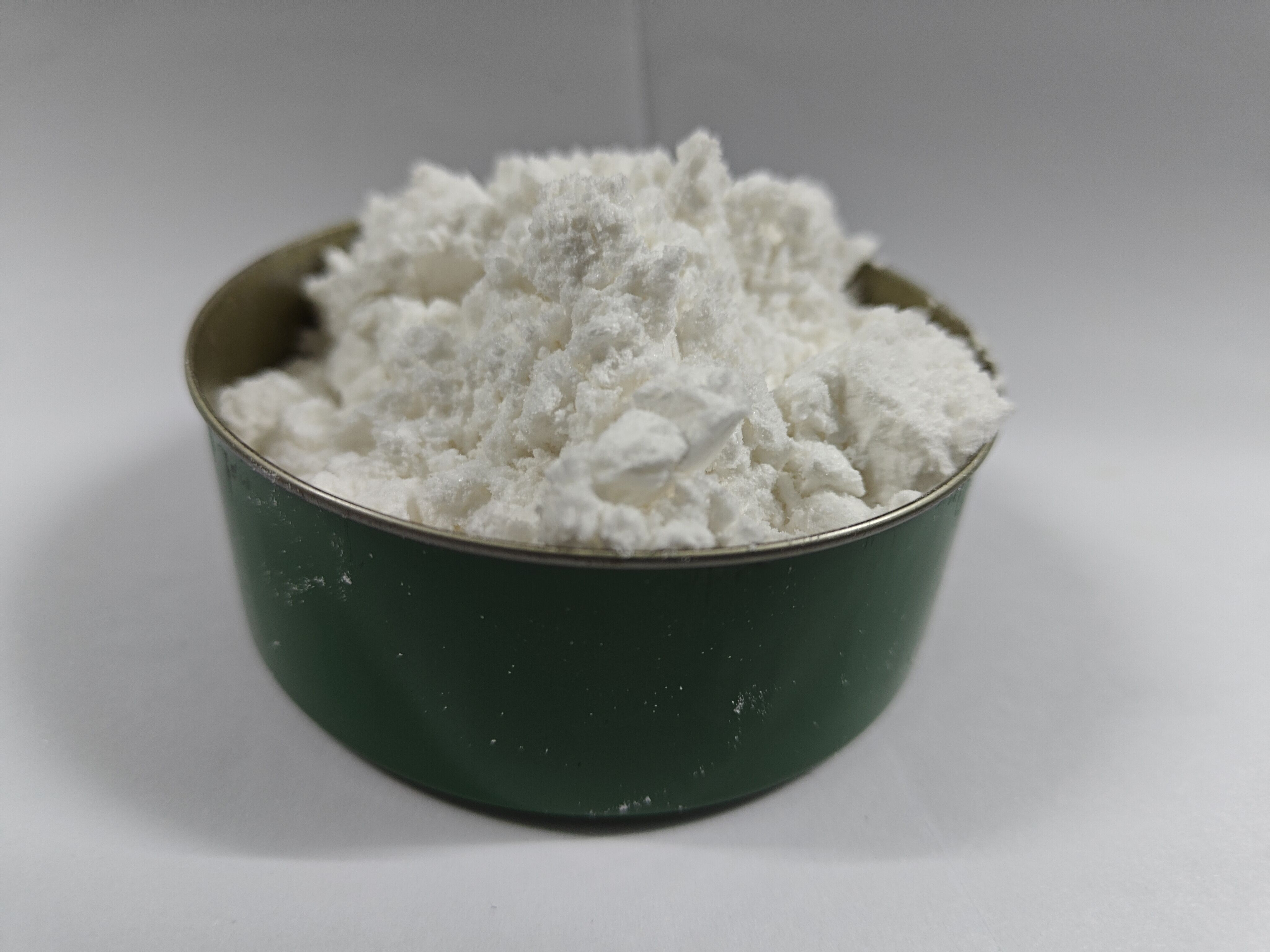

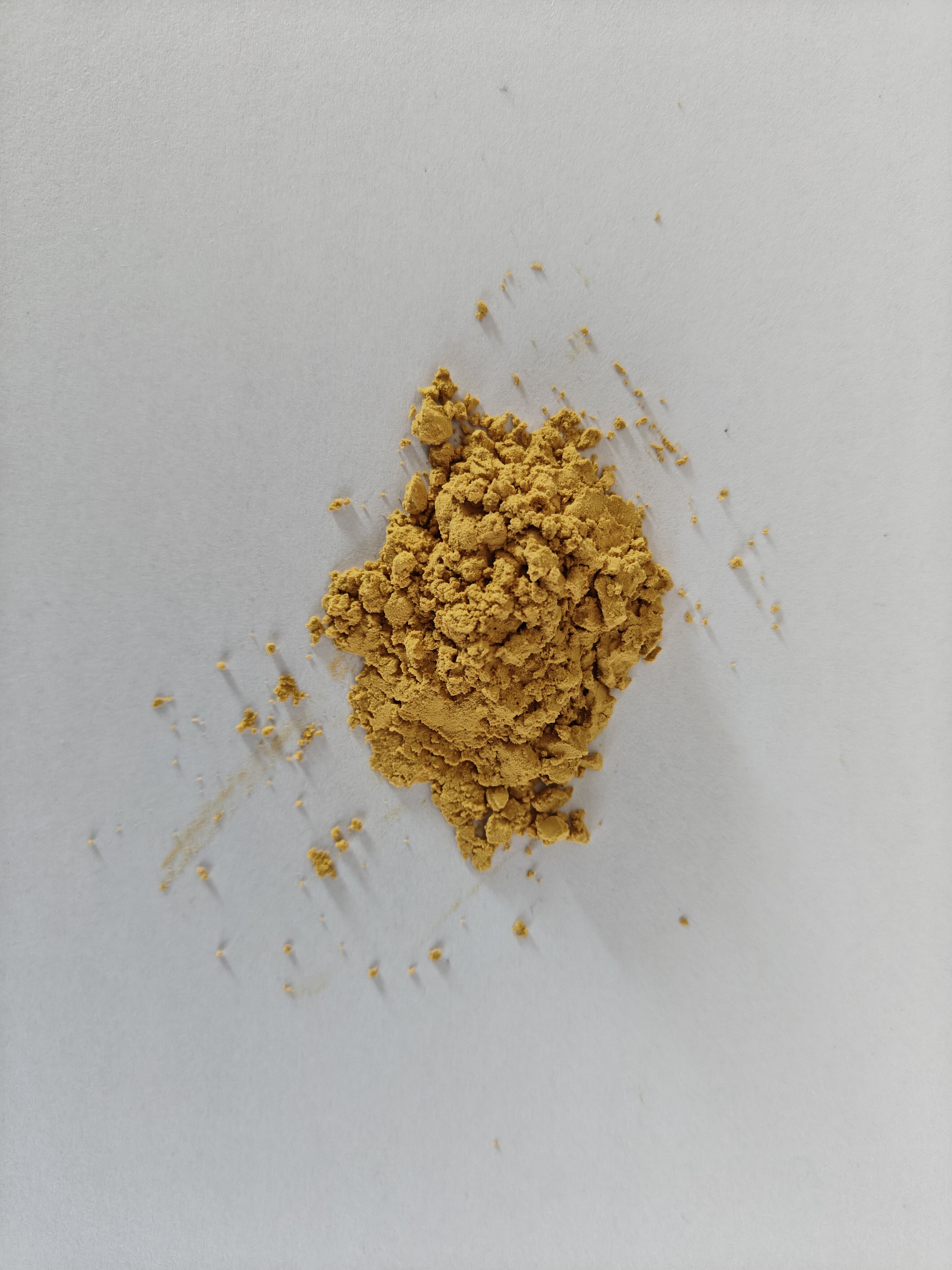

epoxy amine resin

Epoxy amine resin represents a crucial advancement in polymer technology, combining exceptional strength with versatile application potential. This two-component system consists of epoxy resins and amine hardeners that, when mixed, undergo a chemical reaction forming a highly durable cross-linked structure. The resulting material exhibits outstanding adhesion properties, excellent chemical resistance, and remarkable mechanical strength. In industrial applications, epoxy amine resins serve as protective coatings, structural adhesives, and composite matrix materials. Their superior moisture resistance and thermal stability make them ideal for marine environments and high-temperature applications. The curing process can be tailored to specific requirements through careful selection of amine hardeners, offering flexibility in working time and final properties. These resins demonstrate exceptional durability in harsh environments, providing long-term protection against corrosion, chemical exposure, and mechanical stress. Their ability to bond with various substrates, including metals, concrete, and composites, has made them indispensable in construction, automotive manufacturing, and aerospace industries. Furthermore, recent developments in epoxy amine technology have led to enhanced environmental compatibility and improved processing characteristics.