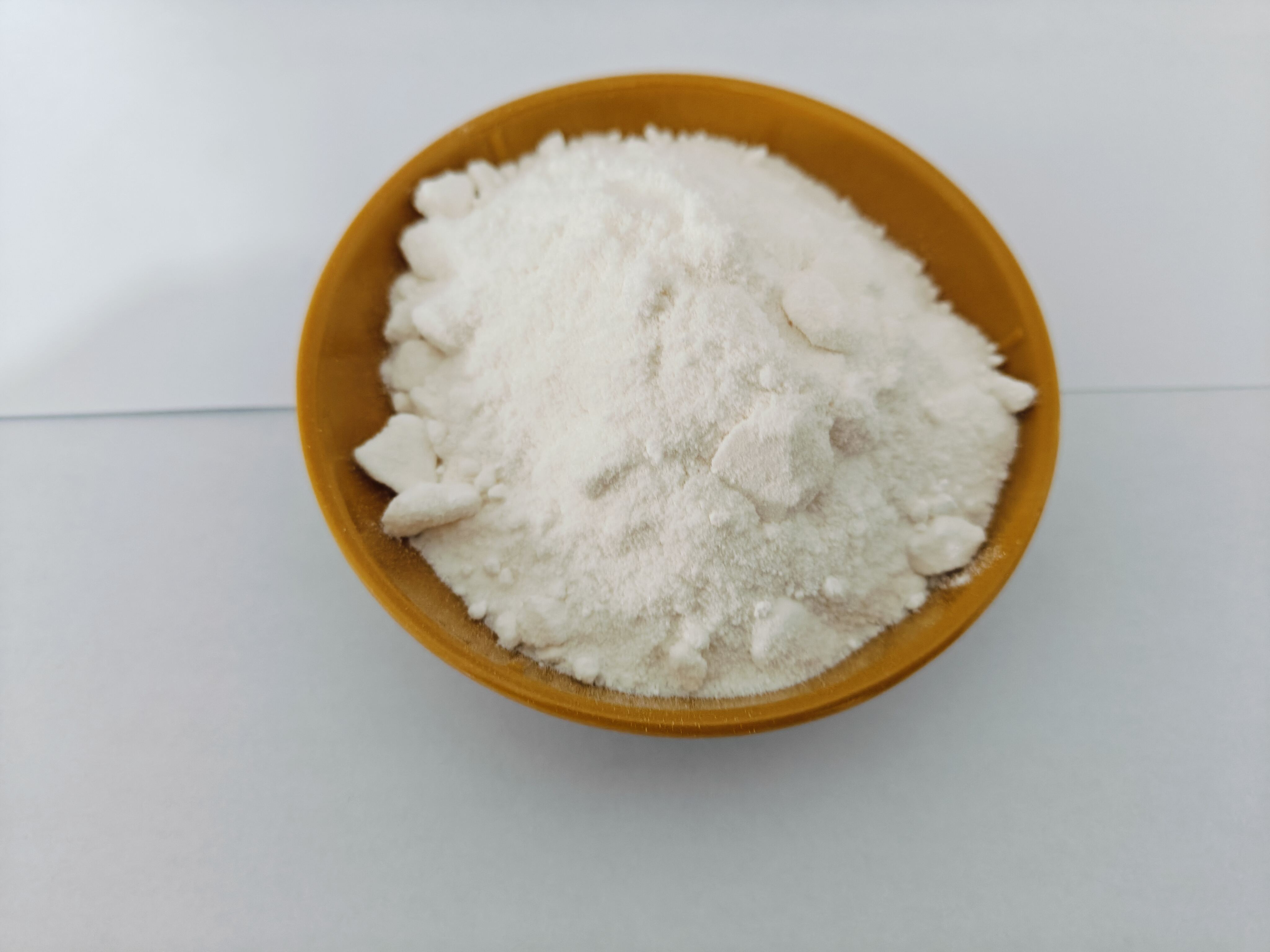

epoxy resin and curing agent

Epoxy resin and curing agent systems represent a cornerstone in modern industrial applications, offering exceptional bonding strength and versatility. These two-component systems work through a chemical reaction where the epoxy resin combines with the curing agent to form a robust, cross-linked polymer network. The resulting material exhibits outstanding mechanical properties, chemical resistance, and durability. When properly mixed, these systems provide excellent adhesion to various substrates, including metals, plastics, wood, and composites. The technology behind epoxy systems has evolved significantly, now offering customizable cure times, temperature resistance ranges, and specific performance characteristics. Applications span across industries, from aerospace and automotive manufacturing to construction and electronics. Modern formulations can be engineered for specific requirements, such as fast curing times, flexibility, or enhanced thermal stability. The system's ability to cure at room temperature or under elevated conditions makes it highly practical for both industrial and DIY applications. Additionally, these systems often feature low shrinkage during cure, excellent electrical insulation properties, and remarkable resistance to environmental factors.