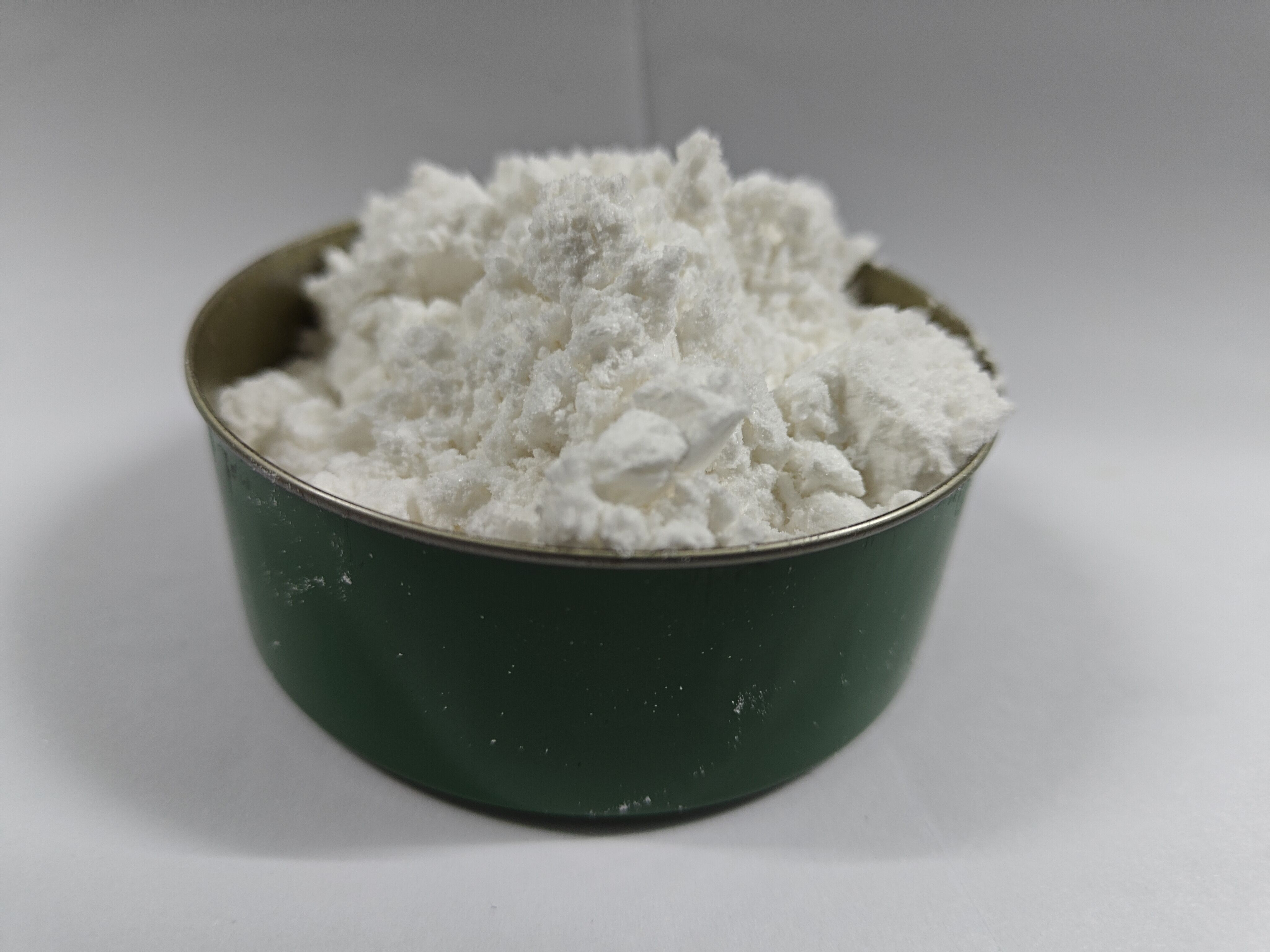

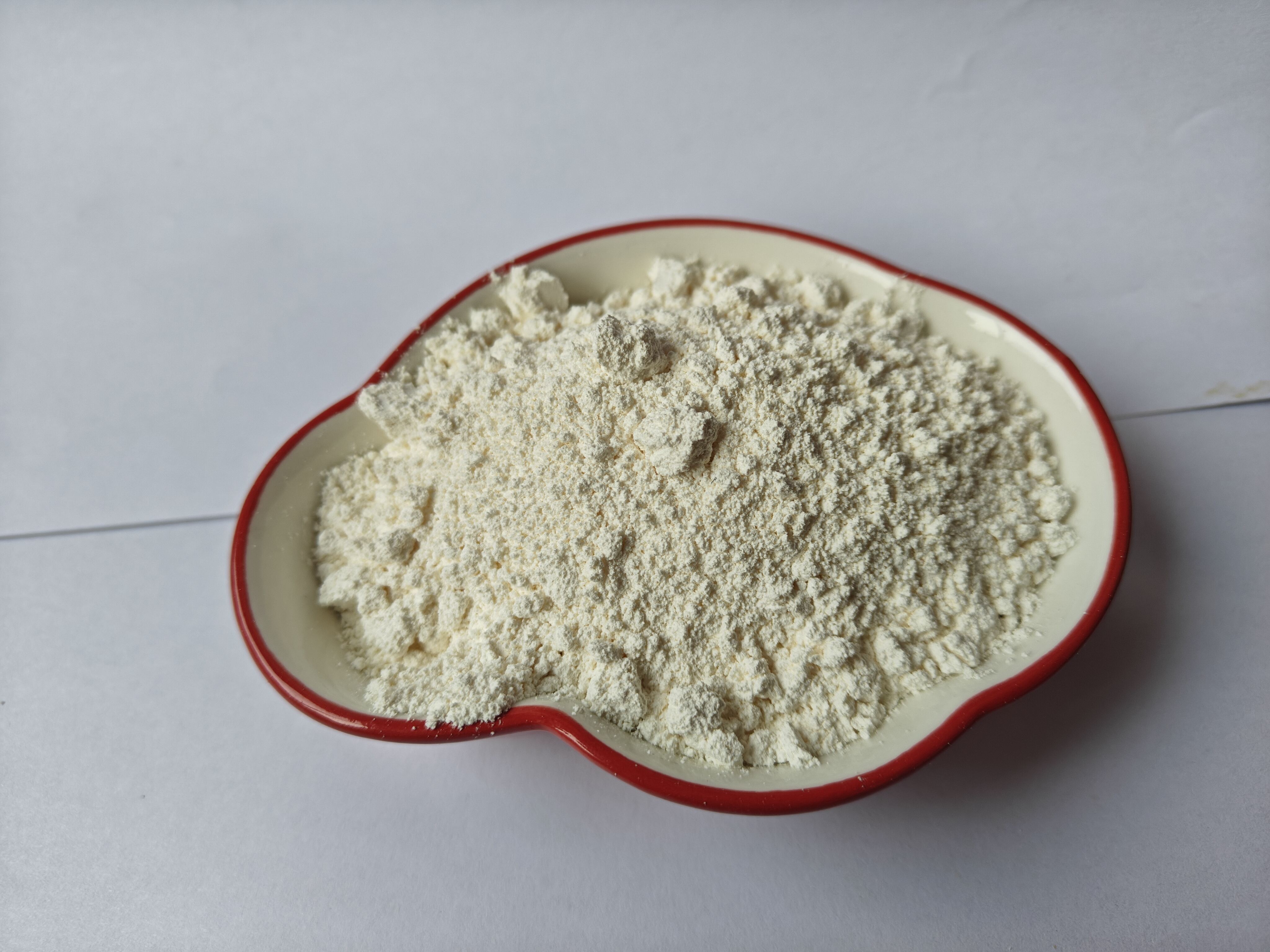

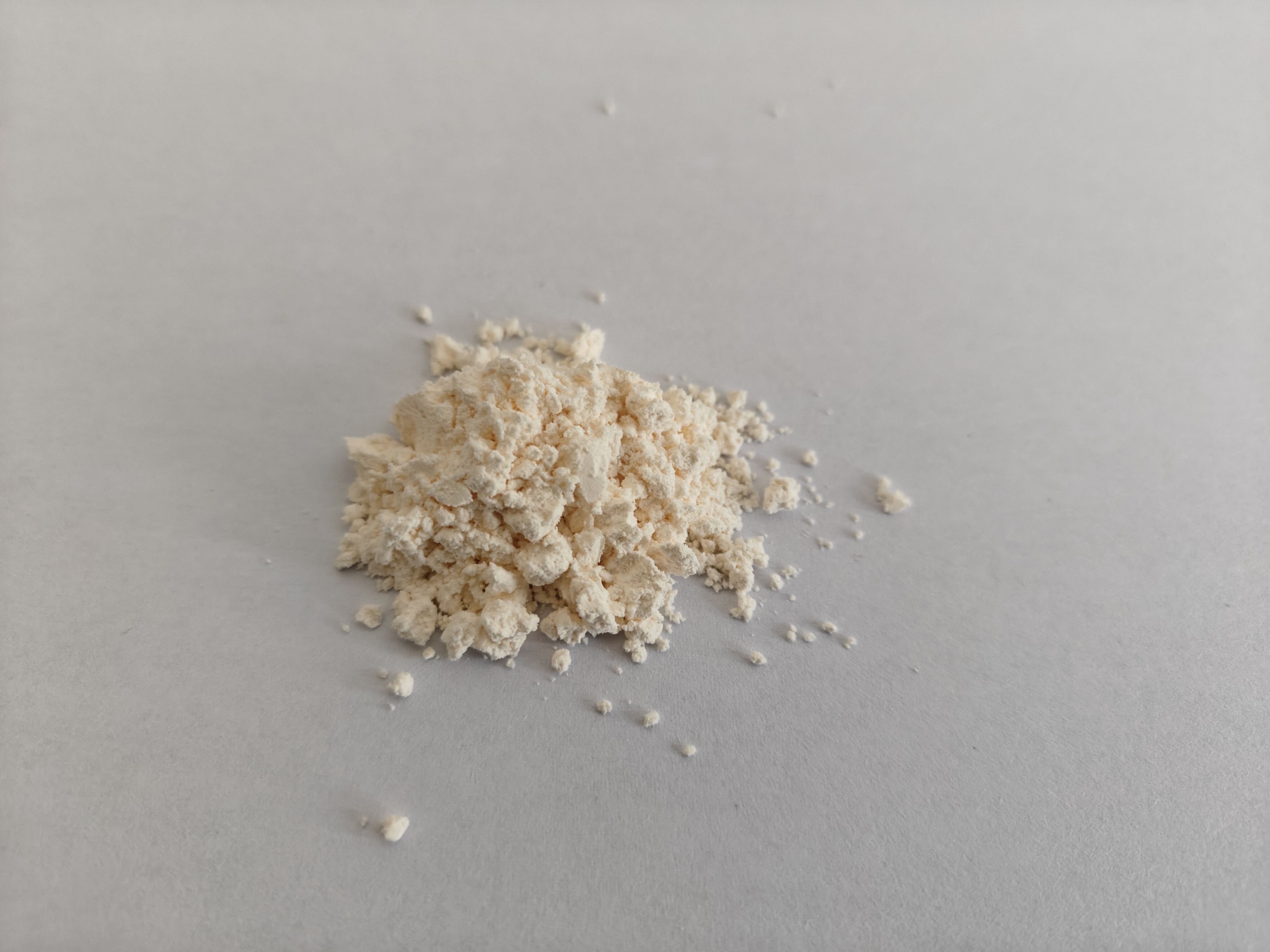

epoxyimidazole catalyst

The epoxyimidazole catalyst represents a groundbreaking advancement in epoxy curing technology, serving as a powerful accelerator for epoxy resin systems. This innovative catalyst operates through a unique mechanism that promotes the ring-opening polymerization of epoxy groups while maintaining excellent control over the curing process. At its core, the catalyst combines the reactivity of imidazole compounds with specialized structural modifications that enhance its performance characteristics. The catalyst demonstrates remarkable efficiency at relatively low loading levels, typically requiring only 0.5-3% by weight to achieve optimal results. Its molecular design allows for superior compatibility with various epoxy resin systems, making it particularly valuable in applications requiring precise cure control and exceptional final properties. The epoxyimidazole catalyst excels in both thermal and latent curing applications, providing users with flexibility in processing conditions while ensuring consistent results. In industrial applications, it has proven especially effective in electronic packaging, composite materials, and high-performance coatings where precise cure control and excellent end properties are essential.