epoxy molding compound prices

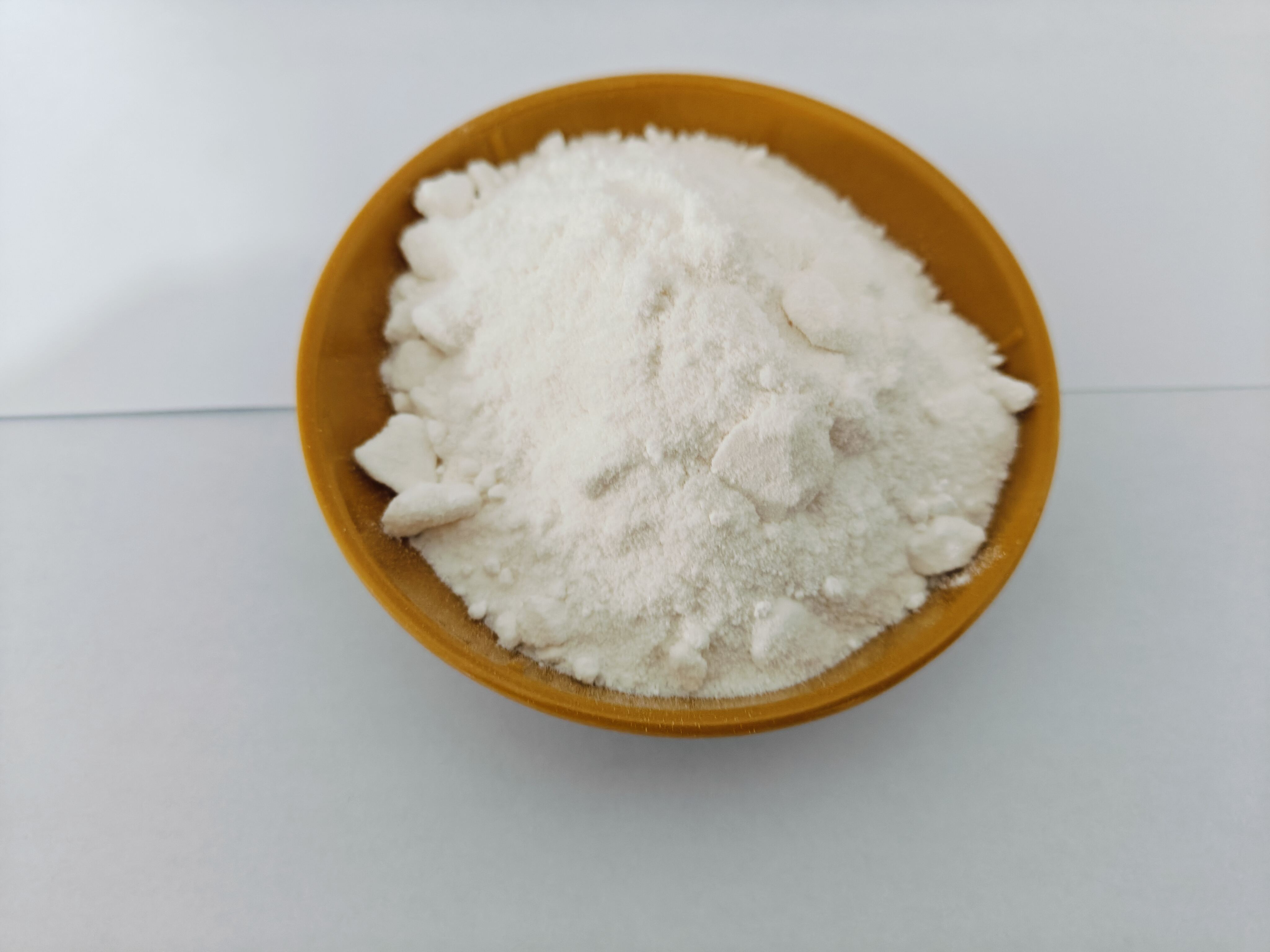

Epoxy molding compound prices represent a crucial factor in the semiconductor and electronic components manufacturing industry. These compounds serve as protective encapsulation materials, safeguarding sensitive electronic components from environmental factors, mechanical stress, and thermal variations. The pricing structure typically varies based on several factors, including material grade, thermal conductivity, flame retardancy, and bulk quantity orders. High-performance grades designed for automotive and aerospace applications command premium prices due to their enhanced thermal and mechanical properties. Standard grades used in consumer electronics generally fall into more moderate price ranges. The market demonstrates price fluctuations influenced by raw material availability, manufacturing capacity, and global demand trends. Recent technological advancements have led to the development of specialized formulations with improved characteristics, such as lower cure temperatures and better flow properties, which may impact pricing structures. Manufacturers often offer different pricing tiers based on volume commitments and long-term supply agreements, allowing customers to optimize their procurement costs while ensuring consistent material quality.