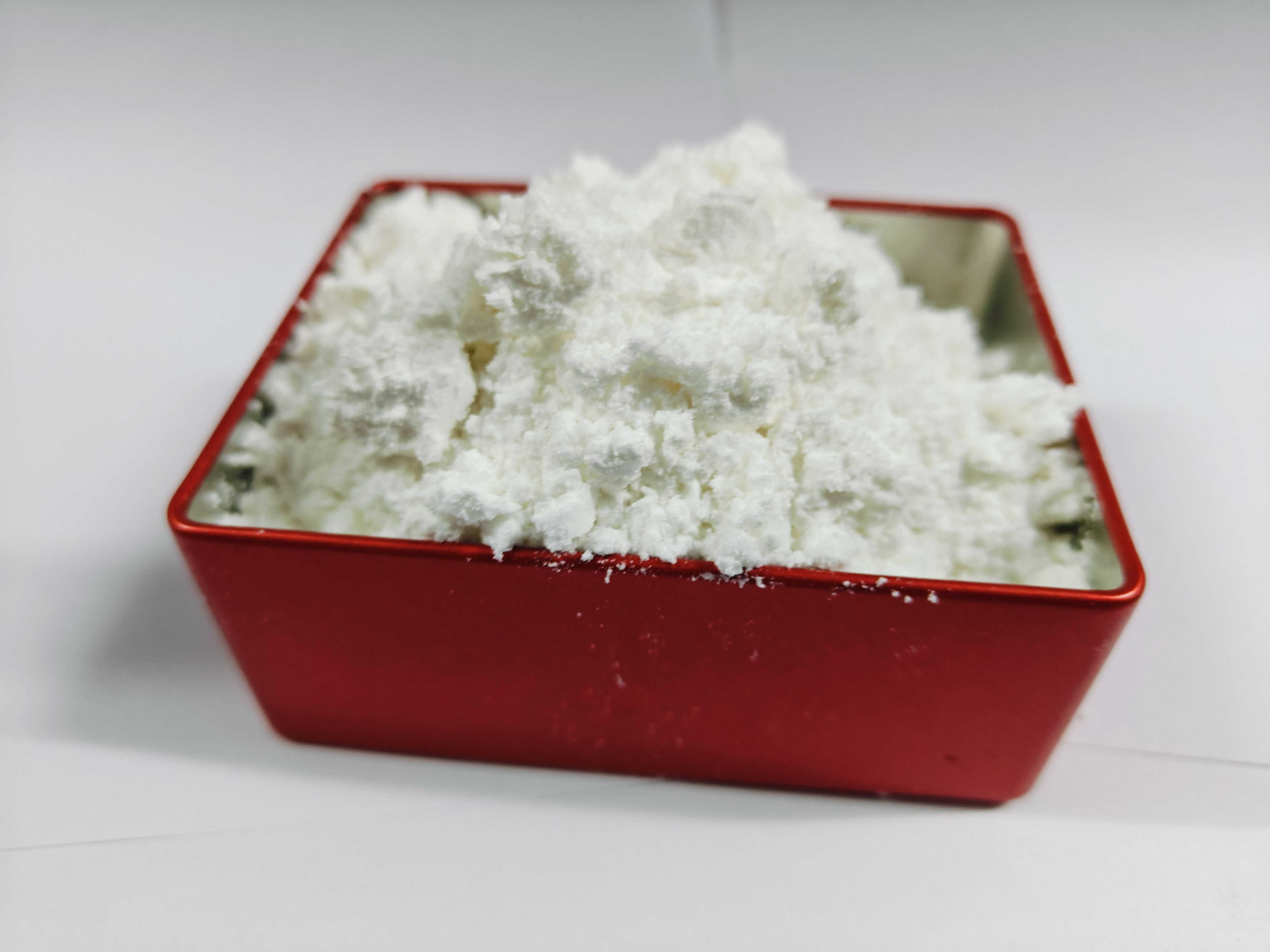

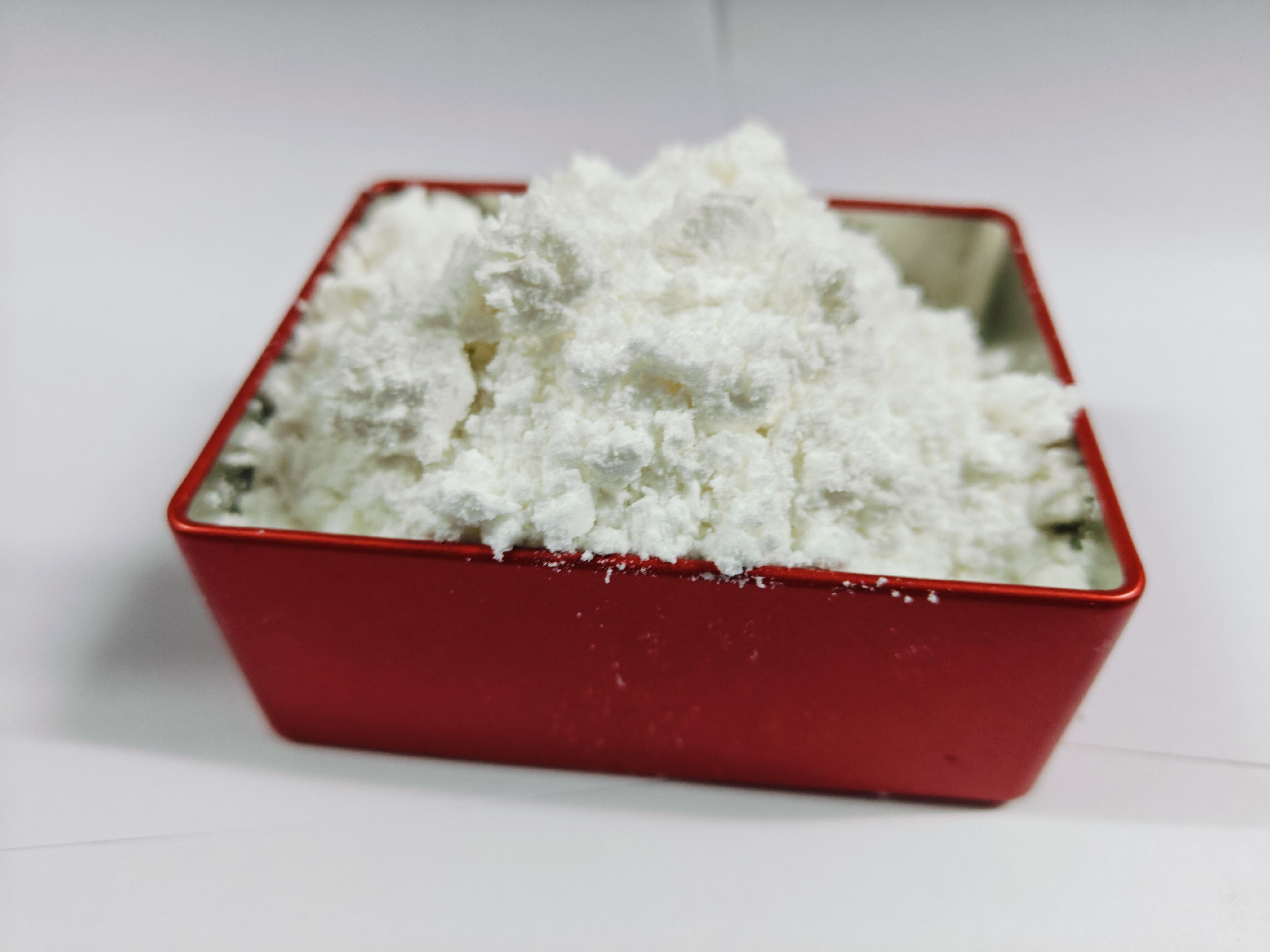

emc curing accelerators for electronics

EMC (Epoxy Molding Compound) curing accelerators for electronics are essential components in modern electronic manufacturing, playing a crucial role in optimizing the encapsulation process of semiconductor devices. These specialized chemical agents are designed to enhance the curing speed and efficiency of epoxy molding compounds, which are widely used to protect electronic components from environmental factors and mechanical stress. The accelerators function by catalyzing the cross-linking reactions in the epoxy resin system, significantly reducing the required curing time and temperature. This advanced technology enables manufacturers to achieve faster production cycles while maintaining the high quality and reliability of electronic components. The accelerators are carefully formulated to ensure compatibility with various epoxy resin systems and to provide optimal curing characteristics without compromising the final properties of the molded package. In the electronics industry, these accelerators are particularly valuable in applications such as integrated circuit packaging, semiconductor encapsulation, and electronic component protection. They contribute to improved production efficiency, reduced energy consumption, and enhanced product performance. The technology behind EMC curing accelerators continues to evolve, with newer formulations offering better control over curing profiles, reduced volatile organic compound emissions, and improved compatibility with increasingly complex electronic designs.