emc curing accelerators factory

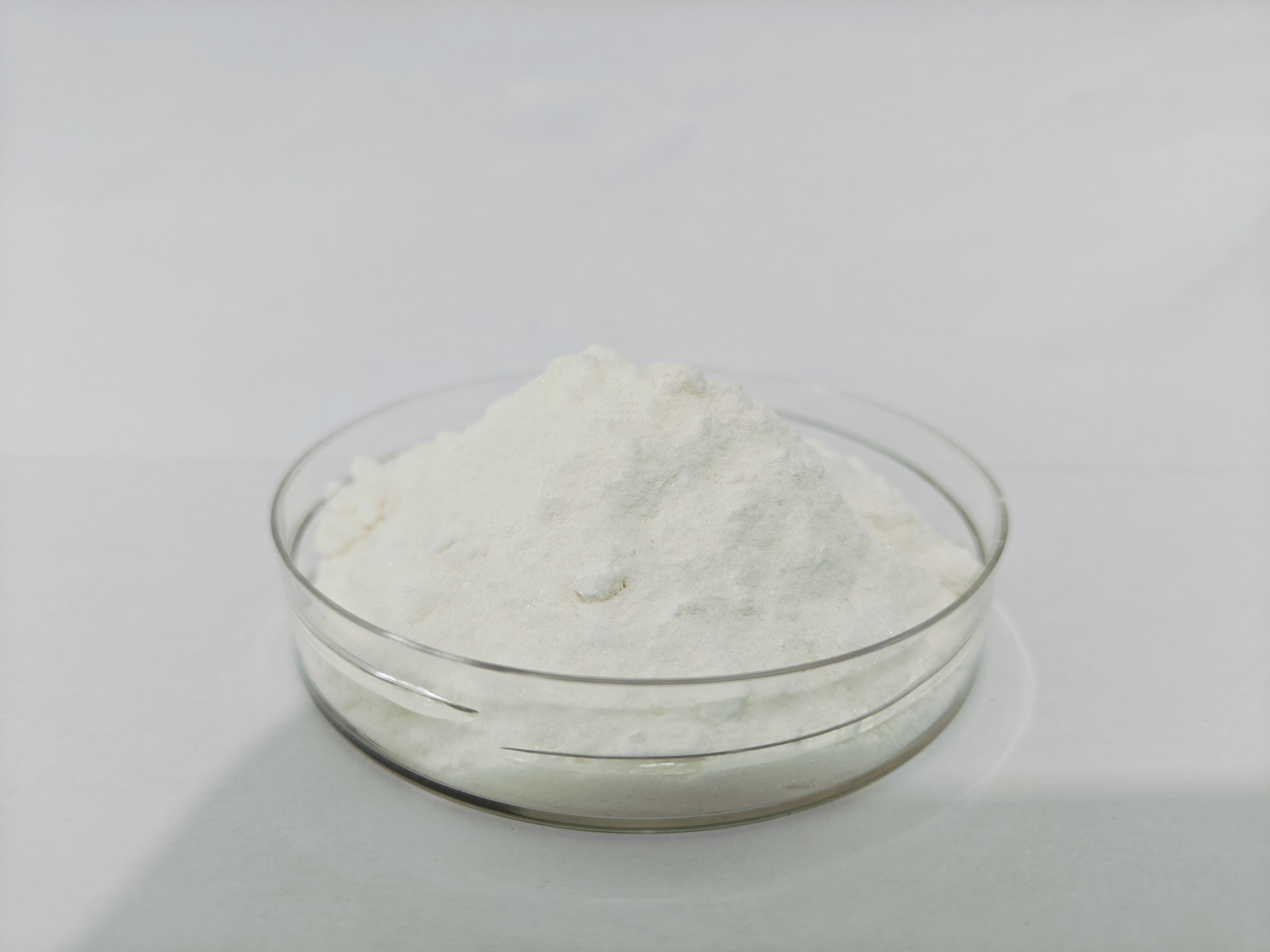

The EMC curing accelerators factory stands as a state-of-the-art manufacturing facility dedicated to producing high-performance curing accelerators for epoxy molding compounds. This advanced facility integrates cutting-edge automation systems and precision control mechanisms to ensure consistent product quality and optimal production efficiency. The factory's core operations involve the synthesis and processing of chemical compounds that enhance the curing process of EMC materials, crucial for semiconductor packaging applications. Equipped with sophisticated quality control laboratories, the facility maintains strict adherence to international manufacturing standards while continuously monitoring product specifications. The production line features advanced mixing technology, temperature-controlled reactors, and automated packaging systems that ensure product stability and reliability. The factory's innovative dust-free environment and contamination control measures guarantee the purity of accelerators, essential for maintaining the integrity of electronic components. With its comprehensive research and development capabilities, the facility constantly develops new formulations to meet evolving industry demands, particularly in the electronics and semiconductor sectors. The factory's commitment to sustainability is evident through its implementation of energy-efficient processes and waste reduction systems, aligning with global environmental standards while maintaining high production outputs.