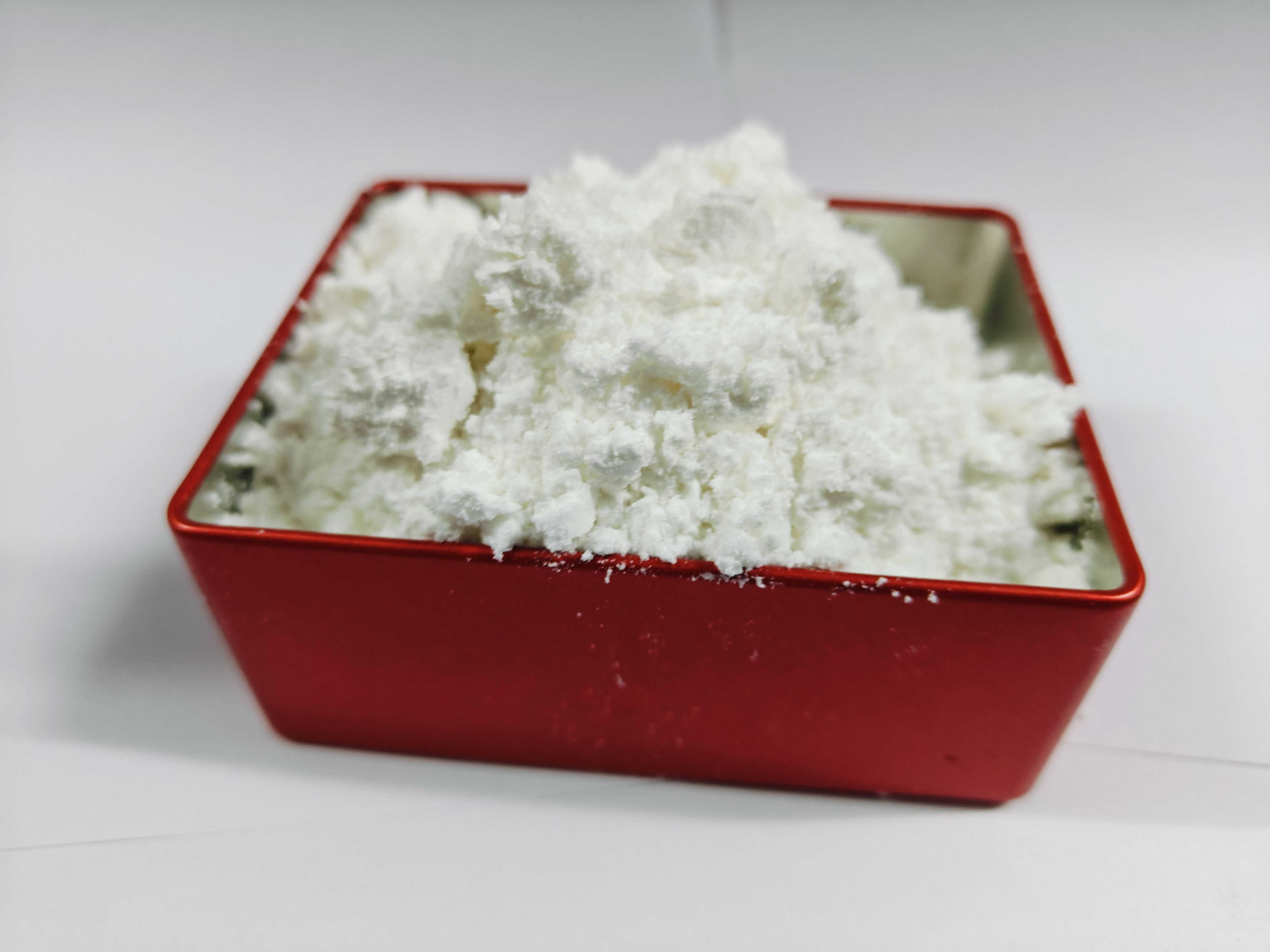

tagapagligaw para sa epoxy resins

Ang isang curing agent para sa mga epoxy resin ay nagsisilbing isang mahalagang katalisador sa pagbabagong-anyo ng likidong epoxy sa matibay, mataas na performance na mga materyales. Ang mga nagpapatibay na ito ay nagsisimula at kumokontrol sa reaksyon ng kemikal na nagbabago ng mga epoxy resin mula sa kanilang paunang likido na estado sa matibay, cross-linked na mga network ng polymer. Ang proseso ng pag-iinit ay nagsasangkot ng tumpak na pag-iitlog ng molekula, kung saan pinapayagan ng ahente ang pagbuo ng malakas na mga tulay ng kemikal sa pagitan ng mga molekula ng epoxy, na nagreresulta sa pambihirang lakas ng mekanikal, paglaban sa kemikal, at katat Ang mga modernong ahente ng pag-aalaga ay idinisenyo upang magbigay ng mga tiyak na katangian ng pagganap, kabilang ang variable na oras ng pag-aalaga, iba't ibang mga kinakailangan sa temperatura, at mga napapasadya na pangwakas na katangian. Makikita nila ang malawak na mga aplikasyon sa buong mga industriya, mula sa konstruksyon at aerospace hanggang sa electronics at paggawa ng kotse. Ang teknolohiya sa likod ng mga ahente ng pag-aalaga ay umunlad upang mag-alok ng pinahusay na kontrol sa mga rate ng pag-aalaga, pinahusay na mga katangian ng paghawak, at mas mahusay na pagkakatugma sa kapaligiran. Karagdagan pa, ang mga advanced na formula ay nagbibigay ngayon ng pinalawak na buhay ng banga habang pinapanatili ang mabilis na kakayahan sa pag-iinit, na ginagawang mainam para sa parehong malalaking mga aplikasyon sa industriya at tumpak na mga espesyal na paggamit. Ang mga ahente na ito ay maaaring mai-tailor sa mga tiyak na kondisyon sa kapaligiran at mga kinakailangan sa aplikasyon, na tinitiyak ang pinakamainam na pagganap sa isang malawak na hanay ng mga antas ng temperatura at kahalumigmigan.