Industri pembungkusan semikonduktor menghadapi cabaran yang semakin kompleks apabila pengecilan peranti menuntut kawalan bahan dan keadaan pemprosesan yang tepat. Antara teknologi utama yang membolehkan penyelesaian pembungkusan lanjutan, katalis termaan laten telah muncul sebagai sebatian revolusioner yang memberikan kawalan belum pernah ada sebelum ini ke atas proses pencuraian. Mangkin khusus ini kekal tidak aktif pada suhu bilik tetapi diaktifkan secara tepat apabila dipanaskan pada tahap suhu tertentu, membolehkan pengilang mengoptimumkan masa, mengurangkan sisa, dan meningkatkan kualiti produk secara keseluruhan dalam operasi perakitan semikonduktor.

Memahami Mekanisme Aktivasi Termal

Kelakuan Mangkin yang Dipicu oleh Suhu

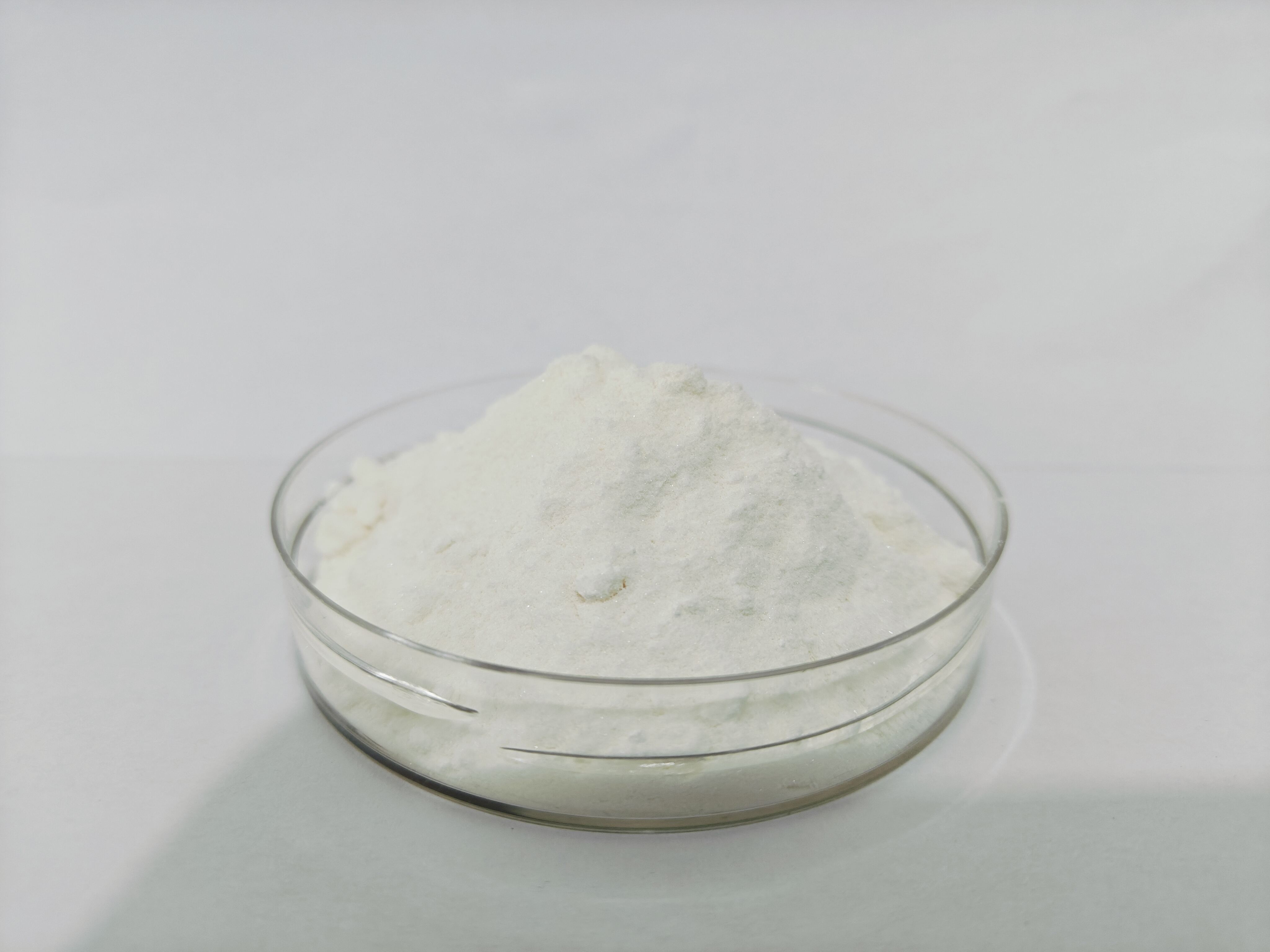

Prinsip asas di sebalik mangkin laten termal terletak pada struktur molekulnya, yang mengalami perubahan konformasi tertentu apabila terdedah kepada julat suhu yang telah ditetapkan. Berbeza dengan mangkin konvensional yang mula bertindak balas serta-merta selepas dicampur, sebatian maju ini mengekalkan kestabilan kimia sehingga aktivasi haba berlaku. Mekanisme aktivasi terkawal ini membolehkan pengilang semikonduktor menyediakan formulasi pelekat, isian bawah dan penyalut jauh lebih awal sebelum proses pemerapan sebenar, meningkatkan ketangkasan dalam penjadualan pengeluaran secara ketara.

Suhu pengaktifan boleh dilaraskan secara tepat melalui kejuruteraan molekul, biasanya berada dalam julat 80°C hingga 200°C bergantung kepada keperluan aplikasi tertentu. Pemilihan suhu ini memastikan pemejalan awal tidak berlaku semasa penyimpanan bahan, pengendalian, atau peringkat pemontaj awal. Molekul pemangkin kekal tidak aktif dalam konfigurasi stabil mereka sehingga tenaga haba yang dikenakan mengatasi halangan pengaktifan, mencetuskan tindak balas pempolimeran atau rangkaian silang yang diperlukan bagi sifat akhir bahan.

Pertimbangan Rekabentuk Molekul

Katalis laten haba maju menggabungkan seni bina molekul canggih yang menyeimbangkan kestabilan dengan kereaktifan. Proses rekabentuk melibatkan pemilihan kumpulan berfungsi secara teliti untuk memberikan suhu pengaktifan yang diingini sambil mengekalkan kestabilan penyimpanan jangka panjang. Sebagai contoh, sebatian berasaskan imidazol menawarkan ciri-ciri laten haba yang sangat baik digabungkan dengan aktiviti pemangkinan yang cekap setelah diaktifkan, menjadikannya sangat sesuai untuk bahan pengepakan semikonduktor berasaskan epoksi.

Faktor berat molekul dan halangan sterik juga memainkan peranan penting dalam menentukan prestasi katalis. Varian berat molekul yang lebih tinggi biasanya menunjukkan tempoh laten yang ditingkatkan, manakala corak penggantian tertentu boleh melaras secara tepat suhu pengaktifan dan kadar aktiviti pemangkinan setelah pencetus haba berlaku. Tahap kawalan molekul ini membolehkan formulator mencipta penyelesaian tersuai untuk aplikasi pengepakan semikonduktor tertentu.

Aplikasi dalam Pengekorian Semikonduktor

Peningkatan Bahan Underfill

Aplikasi underfill mewakili salah satu penggunaan paling kritikal bagi pemangkin laten haba dalam pengekorian semikonduktor. Bahan-bahan ini mesti mengalir dengan berkesan di sekeliling sambungan solder dan bon wayar yang halus sambil mengekalkan kawalan kelikatan yang tepat semasa proses penyedutan. Pemangkin tradisional kerap menyebabkan penggumpalan awal, membawa kepada kesukaran pemprosesan dan kemungkinan kerosakan peranti semasa perakitan.

Penggunaan pemangkin laten haba membolehkan formulasi underfill mengekalkan ciri aliran yang optimum pada suhu bilik sambil memastikan penuaan lengkap apabila perakitan mencapai suhu pemprosesan yang ditetapkan. Kelakuan penuaan terkawal ini menghapuskan risiko pempolimeran tidak lengkap di kawasan teduh serta mencegah tekanan haba pada komponen sensitif semasa peringkat awal kitaran penuaan.

Optimumisasi Formulasi Pengkapsul

Bahan pengkapsul mendapat manfaat besar daripada teknologi pemangkin laten haba, terutamanya dalam aplikasi acuan pemindahan dan acuan mampatan. Proses ini memerlukan bahan yang kekal stabil semasa pengisian acuan sambil mencapai pemerolehan yang cepat dan seragam apabila suhu acuan tercapai. Sifat laten pemangkin ini mengelakkan pautan silang awal yang boleh menyebabkan pengisian acuan tidak lengkap atau kecacatan permukaan.

Formulasi pengkapsul moden yang menggunakan pemangkin laten haba menunjukkan peningkatan dalam sifat mekanikal, pengurangan piuh, dan kebolehpercayaan yang lebih baik di bawah keadaan kitaran haba. Kinetik pemerolehan yang terkawal juga membolehkan pengoptimuman masa kitaran, membolehkan pengilang menyeimbangkan keperluan produktiviti dengan spesifikasi kualiti dalam persekitaran pengeluaran berkelantangan tinggi.

Kawalan Proses dan Manfaat Kualiti

Kelebihan Masa Kerja Lanjutan

Salah satu kelebihan paling ketara yang ditawarkan oleh mangkin laten secara terma ialah pelanjutan masa kerja atau tempoh hayat campuran bagi formulasi reaktif. Sistem mangkin tradisional sering menetapkan batasan masa yang ketat terhadap pengendalian dan aplikasi bahan, memerlukan pemprosesan pantas untuk mengelakkan pencantuman awal. Tekanan masa ini boleh menyebabkan ralat pemprosesan, pembaziran bahan, dan pengurangan fleksibiliti dalam pembuatan.

Sistem laten secara terma menghapuskan batasan masa ini dengan mengekalkan kestabilan bahan pada suhu persekitaran untuk tempoh yang lebih panjang, kadangkala berlangsung berminggu-minggu atau berbulan-bulan bergantung kepada kimia mangkin tertentu. Tempoh kerja yang dipanjangkan ini membolehkan ujian kawalan kualiti yang lebih menyeluruh, pengurusan inventori yang lebih baik, dan fleksibiliti yang lebih tinggi dalam penjadualan pengeluaran tanpa mengorbankan prestasi produk akhir.

Kawalan Suhu Presisi

Mekanisme pengaktifan berdasarkan suhu bagi mangkin ini membolehkan kawalan tepat terhadap profil pemejalan, membolehkan pengilang mengoptimumkan keadaan pemprosesan untuk konfigurasi peranti dan keperluan prestasi tertentu. Tahap kawalan ini amat bernilai dalam aplikasi pengepakan maju di mana pengurusan haba adalah kritikal untuk kebolehpercayaan dan prestasi peranti.

Jurutera proses boleh mereka bentuk profil pemejalan berperingkat yang memanfaatkan ciri-ciri pengaktifan mangkin, dengan potensi menggabungkan peringkat suhu rendah untuk pelepasan tekanan bersama pengaktifan suhu tinggi bagi pempolimeran lengkap. Kelenturan dalam pemprosesan haba ini boleh meningkatkan kadar hasil dan kebolehpercayaan produk akhir secara ketara dalam aplikasi semikonduktor yang mencabar.

Strategi Pengoptimuman Prestasi

Pengoptimuman Pemuatan Mangkin

Kepekatan mangkin yang laten secara terma memerlukan pengoptimuman teliti untuk menyeimbangkan kelajuan pemerolehan dengan sifat bahan dan julat pemprosesan. Pembebanan mangkin yang lebih tinggi biasanya menghasilkan kadar pemerolehan yang lebih cepat setelah pengaktifan berlaku, tetapi ia juga boleh mengurangkan tempoh laten keseluruhan dan menjejaskan sifat mekanikal akhir. Sebaliknya, tahap mangkin yang tidak mencukupi boleh menyebabkan pemerolehan yang tidak lengkap atau masa pemprosesan yang lebih panjang, yang seterusnya memberi kesan kepada kecekapan pengilangan.

Tahap pembebanan mangkin yang optimum biasanya ditentukan melalui penilaian sistematik kinetik pemerolehan, sifat mekanikal, dan ciri-ciri pemprosesan. Teknik analitikal lanjutan seperti kalorimetri penscanan berbeza dan analisis reologi memberikan pandangan berharga mengenai hubungan antara kepekatan mangkin dan prestasi bahan, membolehkan perumus mencapai keseimbangan ideal bagi aplikasi tertentu.

Pertimbangan Keserasian Perumusan

Pelaksanaan berjaya katalis laten secara termal memerlukan perhatian teliti terhadap keserasian formulasi, termasuk interaksi dengan bahan pengisi, aditif, dan komponen reaktif lain. Sesetengah bahan pengisi bukan organik mungkin mempercepatkan pengaktifan katalis atau mengganggu mekanisme laten, manakala aditif lain seperti perangsang lekatan atau ejen pelepas tekanan boleh mempengaruhi kinetik pemejalan.

Pengujian keserasian yang menyeluruh semasa pembangunan formulasi memastikan semua komponen berfungsi secara sinergi untuk mencapai ciri prestasi yang diingini. Pengujian ini biasanya merangkumi kajian penuaan termampat, analisis termal, dan penilaian sifat mekanikal dalam pelbagai keadaan persekitaran bagi mengesahkan kestabilan jangka panjang dan konsistensi prestasi.

Perkembangan dan inovasi masa depan

Seni Bina Katalis Maju

Usaha penyelidikan dan pembangunan terus memfokuskan pada penciptaan arkitektur katalis laten haba yang lebih canggih yang menawarkan ciri prestasi yang dipertingkatkan dan peluang aplikasi yang lebih luas. Reka bentuk molekul baharu yang menggabungkan pelbagai mekanisme pengaktifan, suhu pengaktifan yang boleh diprogram, dan kestabilan alam sekitar yang diperbaiki mewakili arah pembangunan masa depan yang menjanjikan.

Teknologi baharu seperti mikropembungkusan dan mekanisme pelepasan terkawal mungkin membolehkan kawalan yang lebih tepat terhadap masa pengaktifan katalis dan taburan ruang dalam bahan pembungkusan. Pendekatan maju ini boleh membuka peluang aplikasi baharu seperti bahan yang boleh membaik pulih sendiri atau sistem pemerapan adaptif yang bertindak balas terhadap keadaan pemprosesan tertentu.

Pengintegrasian dengan Pengeluaran Pintar

Kelakuan pengaktifan yang boleh diramal bagi mangkin laten secara terma menjadikan mereka calon yang ideal untuk diintegrasikan dengan sistem pembuatan pintar dan teknologi Industri 4.0. Pemantauan masa nyata profil suhu digabungkan dengan pemodelan ramalan pengaktifan mangkin boleh membolehkan kawalan proses dan jaminan kualiti yang lebih tepat dalam operasi pengekodan semikonduktor.

Sistem pemantauan proses lanjutan yang menggunakan mangkin laten secara terma boleh memberikan maklum balas masa nyata tentang kemajuan proses pemerapan, membolehkan strategi kawalan adaptif yang mengoptimumkan keadaan pemprosesan berdasarkan kelakuan bahan sebenar dan bukannya profil masa-suhu yang telah ditetapkan terlebih dahulu. Tahap kecerdasan proses ini boleh meningkatkan kadar hasil dan mengurangkan kebolehubahan dalam persekitaran pembuatan berkelantangan tinggi.

Soalan Lazim

Apakah julat suhu yang biasanya diperlukan untuk pengaktifan mangkin laten secara terma

Kebanyakan mangkin yang paling laten secara terma direka untuk aplikasi pengepakan semikonduktor diaktifkan dalam julat suhu 80°C hingga 200°C, dengan titik pengaktifan khusus yang disesuaikan mengikut keperluan pemprosesan. Suhu pengaktifan boleh dikawal dengan tepat melalui rekabentuk molekul, membolehkan peracik memilih mangkin yang sejajar dengan keupayaan pemprosesan haba sedia ada dan batasan haba peranti.

Berapa lamakah formulasi yang mengandungi mangkin laten secara terma boleh disimpan sebelum digunakan

Kestabilan penyimpanan berbeza bergantung kepada kimia mangkin tertentu dan keadaan penyimpanan, tetapi bahan yang diformulasikan dengan betul biasanya dapat mengekalkan sifatnya selama beberapa bulan hingga lebih setahun apabila disimpan pada suhu bilik. Sesetengah formulasi lanjutan menunjukkan tempoh kestabilan melebihi dua tahun di bawah keadaan terkawal, memberikan kelebihan ketara dalam pengurusan inventori dan perancangan pengeluaran.

Adakah mangkin laten secara terma mempengaruhi sifat mekanikal akhir bahan yang telah dikukuhkan

Apabila dirumuskan dengan betul, mangkin laten secara terma sebenarnya boleh meningkatkan sifat mekanikal akhir dengan membolehkan pengkukuhan yang lebih lengkap dan seragam berbanding sistem mangkin konvensional. Mekanisme pengaktifan terkawal membolehkan ketumpatan silang yang dioptimumkan dan mengurangkan tekanan dalaman, yang sering menghasilkan peningkatan ketahanan, kestabilan haba, dan kebolehpercayaan jangka panjang bahan yang dikukuhkan.

Bolehkah mangkin laten secara terma digunakan bersama-sama dengan sistem mangkin lain

Ya, mangkin laten secara terma sering boleh digabungkan dengan sistem mangkin lain untuk mencipta profil pengkukuhan berperingkat atau mekanisme pengaktifan hibrid. Gabungan ini memerlukan perumusan yang teliti untuk memastikan keserasian dan mengelakkan interaksi yang tidak diingini, tetapi ia boleh memberikan fleksibiliti pemprosesan yang lebih baik dan peningkatan sifat akhir apabila direka dan dioptimumkan dengan betul untuk aplikasi tertentu.

Jadual Kandungan

- Memahami Mekanisme Aktivasi Termal

- Aplikasi dalam Pengekorian Semikonduktor

- Kawalan Proses dan Manfaat Kualiti

- Strategi Pengoptimuman Prestasi

- Perkembangan dan inovasi masa depan

-

Soalan Lazim

- Apakah julat suhu yang biasanya diperlukan untuk pengaktifan mangkin laten secara terma

- Berapa lamakah formulasi yang mengandungi mangkin laten secara terma boleh disimpan sebelum digunakan

- Adakah mangkin laten secara terma mempengaruhi sifat mekanikal akhir bahan yang telah dikukuhkan

- Bolehkah mangkin laten secara terma digunakan bersama-sama dengan sistem mangkin lain