מעבדות ברחבי העולם מתמודדות עם אתגרים הולכים וגrowing בבחירת חומרים כימיים מיוחדים לפעולות סינתזה בהיקף מוגדל. בין תרכובות אלו, nncarbonyldiimidazole מתרגשת כסוכן צימוד חיוני המאפשר סינתזה יעילה של פפטידים, ייצור של תחליפים פרמצבטיים והמרות אורגניות מתקדמות. הבנת מורכבות הקנייה, אבטחת איכות ויחסים עם ספקים הופכת לפרמטר חשוב ביותר בעת מעבר מפרויקטים של סינתזה בקנה מידה מחקרי לפרויקטים תעשייתיים הדורשים גישה מתמדת ל-nncarbonyldiimidazole ברמה גבוהה.

הבנת דינמיקת השוק לקניית כימיקלים מיוחדים

תבונת שרשרת הספק העולמית

השוק הגלובלי ל-nncarbonyldiimidazole משקף מגמות רחבות יותר בייצור כימיקלים מיוחדים, שבהן התמזגות בין ספקים יצרה הן הזדמנויות והן אתגרים עבור בעלי מקצוע בתחום הקנייה. חברות פרמצבטיות גדולות מסתמכות ביתר שאת על שותפויות אסטרטגיות עם יצרנים כימיים מוכרים שמפגינים שליטה עקיבה באיכות וامتثال נומינלי. קשרים אלו כוללים לעיתים קרובות החכרות לטווח ארוך המבטיחות תמחור מועיל, ובו בזמן מבטיחות שרשרת אספקה אמינה להפעלות סינתזה קריטיות.

הבדלים אזוריים ביכולות ייצור משפיעים משמעותית על מחיר וזמינות של nncarbonyldiimidazole בשווקים שונים. ספקים אירופאיים שומרים מסורתית על תקנים איכותיים גבוהים ותיעוד מקיף, מה שהופך אותם לבעלי עניין מועדף ליישומים פארמהמaceutיים רגולטים. יצרנים אסייתיים מציעים לעיתים קרובות יתרונות של תמחור תחרותי תוך הרחבת מערכות ניהול האיכות שלהם כדי לעמוד בתקני הבינלאומי, ויוצרים הזדמנויות חדשות לאסטרטגיות רכש זולות יותר.

דפוסי תנודות במחיר וטרנדים בשוק

ניתוח השוק מראה כי מחירי nncarbonyldiimidazole עוקבים אחרי דפוסים מחזוריים הנגזרים על ידי עלות חומרי הגלם, ניצולת קיבולת הייצור ותנאי הביקוש מsectors המחקר הפקידנטי. צוותי רכש חייבים לפתח מודלים מתוחכמים של תחזית שיכולים להתחשב בגורמים עונתיים בפעילות הסינתזה, מחזורי תפוגת פטנטים ותוכניות פיתוח טיפוליות חדשות שמגדילות את הצריכה של סוכני צימוד.

אסטרטגיות רכש מתקדמות כוללות הקמת רמות מלאי זמינות שמאזנות בין עלויות אחסון לסיכון אבטחת האספקה. מעבדות חכמות מיישמות מערכות אספקה בזמן-מדויק בשילוב עם איסוף מלאי אסטרטגי במהלך תנאים שיוoקיים מועדפים, מה שמבטיח גישה בלתי-מנוכת ל-nncarbonyldiimidazole תוך כדי אופטימיזציה של העלות הכוללת לאורך תוכניות סינתזה רב-שנתיות.

הערכת איכות וניהול דרישות טכניות

דרישות בדיקות אנליטיות

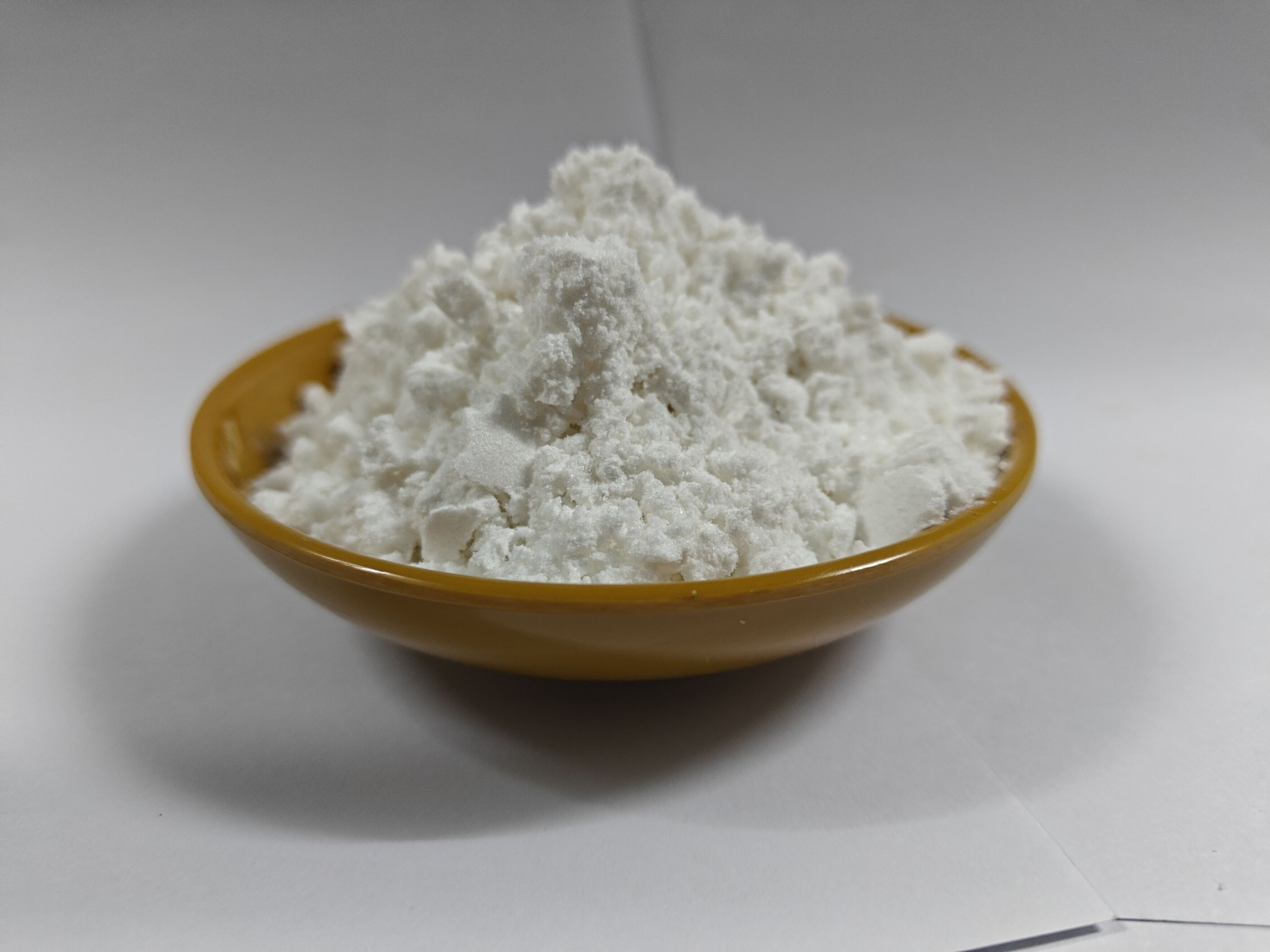

פרוטוקולי הערכת איכות מקיפים עבור nncarbonyldiimidazole חייבים להתייחס למספר פרמטרים אנליטיים, כולל רמות טהרה, תוכן רטיבות, מסיסנים שאריתית והזנות מתכות זעירות. מעבדות מיישמות גישות בדיקה מרובות המתבססות על אימות חומרים נכנסים ודגימת דגימות מחזורית כדי להבטיח איכות עקיבה לאורך תקופות אחסון ארוכות. טכניקות אנליטיות מתקדמות כגון כרומטוגרפיה נוזלית בעלת ביצועים גבוהים וספקטרוסקופיית תהודה מגנטית גרעינית מספקות אפיון חד-משמעי של דוגמיות nncarbonyldiimidazole.

דרישות תאימות רגולטוריות משתנות בצורה משמעותית בין יישומים שונים ואזורים גאוגרפיים, ולכן נדרשים מערכות ניהול איכות גמישות המסוגלות לעמוד בסטים מגוונים של דרישות. יישומים פארماцевטיים מצריכים בדרך כלל דירוג תערובות זרות מקיף ונתוני יציבות, בעוד שמחקרים אקדמיים עשויים להתמקד בעיקר בצניעת כימית ובתכונות ביצועי תגובה. ניהול איכות יעיל כולל הגדרת היררכיות ברורות של דרישות המותאמות לדרישות השימוש הנועד עם פרוטוקולי בדיקה מתאימים.

תכניות אישור וה ביקורת ספקים

תכניות איכותנות ספקים ערכיות מעריכות יכולות ייצור, מערכות איכות ורשומות תאימות רגולטורית לפני כינון יחסים של קנייה עבור nncarbonyldiimidazole. ביקורות מקיפות בודקות מתקני ייצור, מעבדות אנליטיות ומערכות תיעוד כדי לאמת התיישבות עם עקרונות ייצור טובים ותקנים בינלאומיים לאיכות. הערכות אלו כוללות לעיתים קרובות ביקורים באתר, הצגת יכולות ודוחות ביצועים היסטוריים.

ניהול ספקים מתמשך כולל ניטור ביצועים שגרתי, ניתוח מגמות איכות וიוזמות שיפור מתמידים שמטרתם לחזק שותפויות ארוכות טווח. תכניות יעילות מגדירות מדדי ביצועי מפתח, הכוללים אחוזי משלוח בזמן, אחוזי קבלה באיכות ותגובתיות לתמיכה טכנית. סקירות עסקיות שגרתיות מקדמות פתרון בעיות בשיתוף פעולה ותכנון אסטרטגי שמועיל הן למעבדות והן nN-קרבונילדיימידאזול .

תכנון סינתזה בקנה מידה גדול ומדיניות רכש

חיזוי ביקוש ותכנון קיבולת

תחזית דרישה מדויקת של nncarbonyldiimidazole דורשת מודלים מתוחכמים הכוללים התקדמות בקיבולת המחקר, לוחות זמנים של ניסויים קליניים, ולוחות ייצור מסחריים. מעבדות חייבות לאזן בין אי-הוודאות הטמונה במחקרים בשלבים מוקדמים לבין הצורך בתכנון שרשרת אספקה מהימן שתאפשר פעולות הגדלה מוצלחות. מערכות תחזית מתקדמות משקללות מקורות מידע מרובים, ביניהם דפוסי צריכה היסטוריים, לוחות זמנים של צירי דרך של פרויקטים, וחיזוי שוק.

תכנון קיבולת מתרחב מעבר לחישובי נפח פשוטים וכולל תשתית אחסון, ציוד טיפול ומערכות ניהול פסולת הנדרשות לשימוש בקנה מידה גדול בננקארבונילדיימידאזול. שיקולי בריאות ובטיחות סביבתית הופכים לחשובים יותר ככל שנפחי השימוש גדלים, ודורשים תנאי אחסון מיוחדים ואמצעי טיפול שמטרתם לשמור על שלמות המוצר תוך הגנה על עובדים ועל המתקנים.

ניהול סיכונים ותכנון הגנתיות

אסטרטגיות ניהול סיכון מקיפות עונות על הפרעות אפשריות בשורת האספקה שעלולות להשפיע על זמינות הננקארבונילדיימידאזול במהלך קמפיינים קריטיים של סינתזה. תכנון יזום אפקטיבי כולל זיהוי ספקים חלופיים, הקמת הליכי רכש לשעת חירום ושימור מלאי אסטרטגי שיוצר גמישות תפעולית בתנאי שוק בלתי צפויים או הפרעות באספקה.

הפחתת סיכון פיננסי כוללת אסטרטגיות הגנה המאפשרות מגן מפני תנועות מחיר לרעה, תוך שמירה על גמישות באספקה. מעבדות מסוימות משתמשות בחוזים עתידיים או הסכמים אופציונליים המבטיחים תמחור מועיל לקניית nncarbonyldiimidazole בעתיד, תוך שימור היכולת להתאים כמויות בהתאם לדרישות פרויקט משתנות ולתנאי שוק.

שילוב טכנולוגיה ופתרונות רכש דיגיטליים

פלטפורמות רכש אלקטרוני

פעולות רכש מודרניות מסתמכות ביתר תלמידה על פלטפורמות אלקטרוניות מתוחכמות אשר מפשטות את תהליכי קניית nncarbonyldiimidazole, ומספקות נראות משופרת לביצועי ספקים ולתנאי שוק. מערכות אלו מתמזגות עם תוכנות תכנון משאבי יזמה (ERP) כדי לאמת תהליכי הזמנה חוזרת, לעקוב אחר רמות המלאי, ולממש החלטות רכש אופטימליות בהתבסס על נתוני צריכה בזמן אמת ואלגוריתמי תחזית.

פלטפורמות רכש מתקדמות כוללות קטלוגי ספקים, מסדי נתונים של מחירים ורשומות זכאות המאפשרים הערכה מהירה של אפשרויות מקורות ל- nncarbonyldiimidazole. אינטגרציה עם מערכות ניהול נתונים אנליטיים מאפשרת מעקב חלק בתכונות איכות ומידע על יוחסין שורה התומך בהתאמות נהלים והחקירות איכות לאורך שרשרת האספקה.

נראות ואנליזה של שרשרת האספקה

נראות משופרת של שרשרת האספקה מאפשרת ניהול פרואקטיבי של קניית nncarbonyldiimidazole באמצעות תצפית בזמן אמת בביצועי הספקים, רמות המלאי והתנאים בשוק. פלטפורמות אנליטיקה מתקדמות מעבדות כמויות עצומות של נתונים לזיהוי מגמות, חיזוי הפרעות פוטנציאליות והמלצה על אסטרטגיות אופטימיזציה לשיפור היעילות עלות וביטחון האספקה.

יכולות של אנליטיקה חיזוי מסייעות למעבדות לחזות תנודות בביקוש ל-nncarbonyldiimidazole ולתאם אסטרטגיות קנייה בהתאם. אלגוריתמי למידת מכונה מנתחים דפוסים היסטוריים, מדדי שוק ורמות פעילות מחקר כדי ליצור תחזיות מדויקות התומכות בקבלת החלטות אסטרטגיות ובتوزيع משאבים בתוכניות סינתזה מורכבות.

דרישות תאימות רגולטוריות ותיעוד

תקנים בינלאומיים והנחיות

הامتثال הרגולטורי לקניית nncarbonyldiimidazole מעורב בניסיון להבין את הסטנדרטים הבינלאומיים המורכבים המנחים ייצור כימי, תחבורה ונהלי טיפול. מסגרות רגולטוריות שונות דורשות דוקומנטציה מסוימת, פרוטוקולי בדיקה והכשרת ספקים שצריכים להدارש בזהירות לאורך כל תהליך הקנייה. הבנת דרישות אלו מאפשרת למעבדות לבחור ספקים מתאימים ולהקים הליכי רכש מותאמים.

דרישות של תהליכי ייצור טובים משפיעות באופן משמעותי על החלטות הקנייה של nncarbonyldiimidazole, במיוחד ביישומים פ harmaceutיים שבהם רשויות רגולטוריות דורשות תוכניות מוסמכות לאימות ספקים ומעקב מתמיד. מסמכי התאמה חייבים להוכיח עמידה בתקני איכות, הליכי בקרת שינויים והליכי חקירת חריגות שמונעים את שלמות המוצר לאורך כל שרשרת האספקה.

ניהול מסמכים וד Immability

מערכות ניהול מסמכים מקיפות מבטיחות ד Immability מלאה של nncarbonyldiimidazole מהייצור ועד לשימוש הסופי בסינתזות. פלטפורמות דיגיטליות לניהול מסמכים מקלות על אחסון, חיפוש ושיתוף יעיל של אישורי אנליזה, גיליונות נתונים בטיחות ורשומות אימות ספקים התומכות בבדיקות רגולטוריות וחקר איכות.

מערכות מעקב אחר שורה מספקות מידע מפורט על יוחסין, המאפשר זיהוי מהיר של חומרים נפגעים במקרה של בעיות איכות או ספקים. מערכות אלו בדרך כלל מתוותבות עם פלטפורמות לניהול מידע מעבדתי כדי ליצור זרימת נתונים חלקה שתומכת גם ביעילות תפעולית וגם בדרישות תאימות רגולטוריות לשימוש ב-nncarbonyldiimidazole.

שאלות נפוצות

אילו גורמים קובעים את רמת המלאי האופטימלית של nncarbonyldiimidazole בפעולות סינתזה בה 욤?

רמות מלאי אופטימליות של nncarbonyldiimidazole תלויות בקצב הצריכה, זמני מוביל של הספקים, מגבלות קיבולת אחסון ומאפייני יציבות המוצר. מעבדות שומרות בדרך כלל על מלאי של 3–6 חודשים בהתאם ללוחות הסינתזה המתוכננים, תוך לקיחה בחשבון תנודות ביקוש אפשריות וסיכוני שרשרת האספקה. מודלים מתקדמים לאופטימיזציה של מלאי שוקלים את עלויות החזקה, סיכוני התיישנות וההשפעה של מחסור במלאי על לוחות הזמנים הקריטיים של הסינתזה.

כיצד מעבדות מעריכות את יכולות הספקים לרכישת nncarbonyldiimidazole בקנה מידה גדול

הערכת ספקים כוללת הערכה מקיפה של כושר הייצור, מערכות איכות, תיעוד עמידה בתקנות ויכולות התמיכה הטכנולוגית. קריטריוני ההערכה המרכזיים כוללים היקף ייצור ניתן להרחבה, יכולות בדיקה אנליטית, עמידות שורת האספקה והישגון בהקמת שותפויות מוצלחות עם ארגונים דומים. בדרך כלל, מעבדות מבצעות ביקורות מפורטות, בדיקות הפניות ורכישות ניסיוניות לפני הקמת יחסים אסטרטגיים לרכישת nncarbonyldiimidazole.

מהן בעיות האיכות הנפוצות ביותר שנתקלים בהן ברכישת nncarbonyldiimidazole

בעיות איכות נפוצות כוללות זיהום של לחות, רמות שאריות העולות על المواصفים, בעיות של שלמות אריזה וטעויות בדוקומנטציה. רגישות ללחות מחייבת הליכי טיפול ואחסון זהירים, בעוד ששליטה בשאריות תלויה בתהליכי הייצור של הספק והפרוטוקולים לבדיקה אנליטית. ניהול איכות יעיל כולל הליכי בדיקה upon קבלה, תנאי אחסון מתאימים ותקשורת מתמדת עם ספקים בנוגע לציפיות לביצועים ולאפשרויות שיפור.

איך תנאים שוקיים משפיעים על מחירי הפניב-carbonyldiimidazole ועל הזמינות שלו

תנאי השוק משפיעים באופן משמעותי על מחירי nncarbonyldiimidazole דרך תנודות במחירי חומרי הגלם, ניצולת קיבולת הייצור והביקוש מתחומי מחקר פארמאцевטיים. מגבלות באספקה עלולות להתרחש עקב תחזוקת מתקני ייצור, בעיות רגולטוריות או עלייה בביקוש מפרויקטים פארמה מרכזיים. אסטרטגיות קנייה מוצלחות כוללות מעקב שוק, התמקצעות ספקים וגישות חוזים גמישות שמבטיחות הן אופטימיזציה של עלויות והן ביטחון אספקה עבור פעולות סינתזה קריטיות.

תוכן העניינים

- הבנת דינמיקת השוק לקניית כימיקלים מיוחדים

- הערכת איכות וניהול דרישות טכניות

- תכנון סינתזה בקנה מידה גדול ומדיניות רכש

- שילוב טכנולוגיה ופתרונות רכש דיגיטליים

- דרישות תאימות רגולטוריות ותיעוד

-

שאלות נפוצות

- אילו גורמים קובעים את רמת המלאי האופטימלית של nncarbonyldiimidazole בפעולות סינתזה בה 욤?

- כיצד מעבדות מעריכות את יכולות הספקים לרכישת nncarbonyldiimidazole בקנה מידה גדול

- מהן בעיות האיכות הנפוצות ביותר שנתקלים בהן ברכישת nncarbonyldiimidazole

- איך תנאים שוקיים משפיעים על מחירי הפניב-carbonyldiimidazole ועל הזמינות שלו