सबसे अच्छे तापमान पर निर्भर कैटलिस्ट

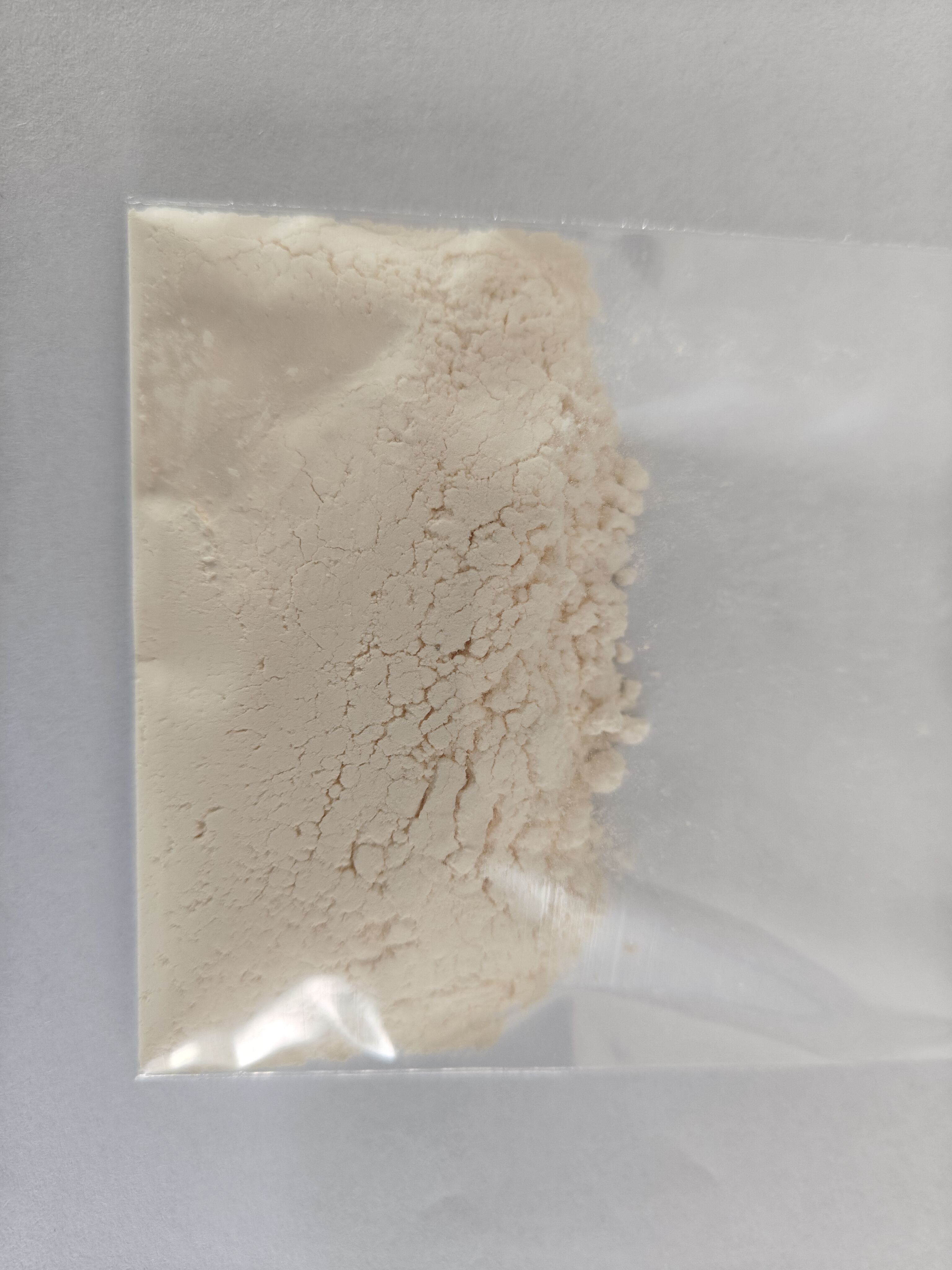

तापीय छिपे हुए कैटलिस्ट आधुनिक रासायनिक प्रसंस्करण और निर्माण में एक विप्लवात्मक सफलता का प्रतिनिधित्व करते हैं। ये उन्नत कैटलिस्ट कमर तापमान पर निष्क्रिय रहते हैं, लेकिन जब विशिष्ट तापमान सीमाओं को प्रदर्शित किया जाता है, तो वे बिल्कुल सटीक रूप से सक्रिय हो जाते हैं, रासायनिक प्रतिक्रियाओं पर अभूतपूर्व नियंत्रण प्रदान करते हैं। इन कैटलिस्ट का मुख्य कार्य यह है कि वे केवल जब चाहिए तब रासायनिक प्रतिक्रियाओं को शुरू करने और तेजी से करने की क्षमता होती है, जिससे वे विभिन्न औद्योगिक अनुप्रयोगों में अमूल्य हो जाते हैं। ये कैटलिस्ट नवीन आणविक डिज़ाइन को अपनाते हैं जिसमें तापमान-संवेदनशील बंधन या संरचनाएँ शामिल हैं, जो निर्धारित तापमानों पर नियंत्रित रूप से परिवर्तित होती हैं। इस विशेष विशेषता के कारण निर्माताओं को इन कैटलिस्ट को सुरक्षित रूप से भंडारित, परिवहित और दैनिक तापमान पर संभालने की क्षमता होती है, जबकि उनकी पूरी कैटलिस्ट क्षमता बनी रहती है। औद्योगिक अनुप्रयोगों में, तापीय छिपे हुए कैटलिस्ट पॉलिमर क्यूरिंग, कोटिंग प्रौद्योगिकियों और चिपकन सिस्टम्स जैसी प्रक्रियाओं को क्रांति ला रहे हैं। वे ऐसे अनुप्रयोगों में उत्कृष्ट हैं जहाँ सटीक प्रतिक्रिया समय और नियंत्रित प्रसंस्करण खंडों की आवश्यकता होती है, विशेष रूप से ऑटोमोबाइल कोटिंग, इलेक्ट्रॉनिक सामग्री और उन्नत चक्रीय निर्माण में। इन कैटलिस्ट के पीछे की प्रौद्योगिकी अभी भी विकसित हो रही है, हालिया विकास उनकी स्थिरता में सुधार, उनकी तापमान सक्रियण सीमाओं को फैलाने और विभिन्न रासायनिक प्रक्रियाओं में उनकी समग्र कुशलता में सुधार करने पर केंद्रित है।