νεότεροι θερμικά καθυστερημένοι καταλύτες

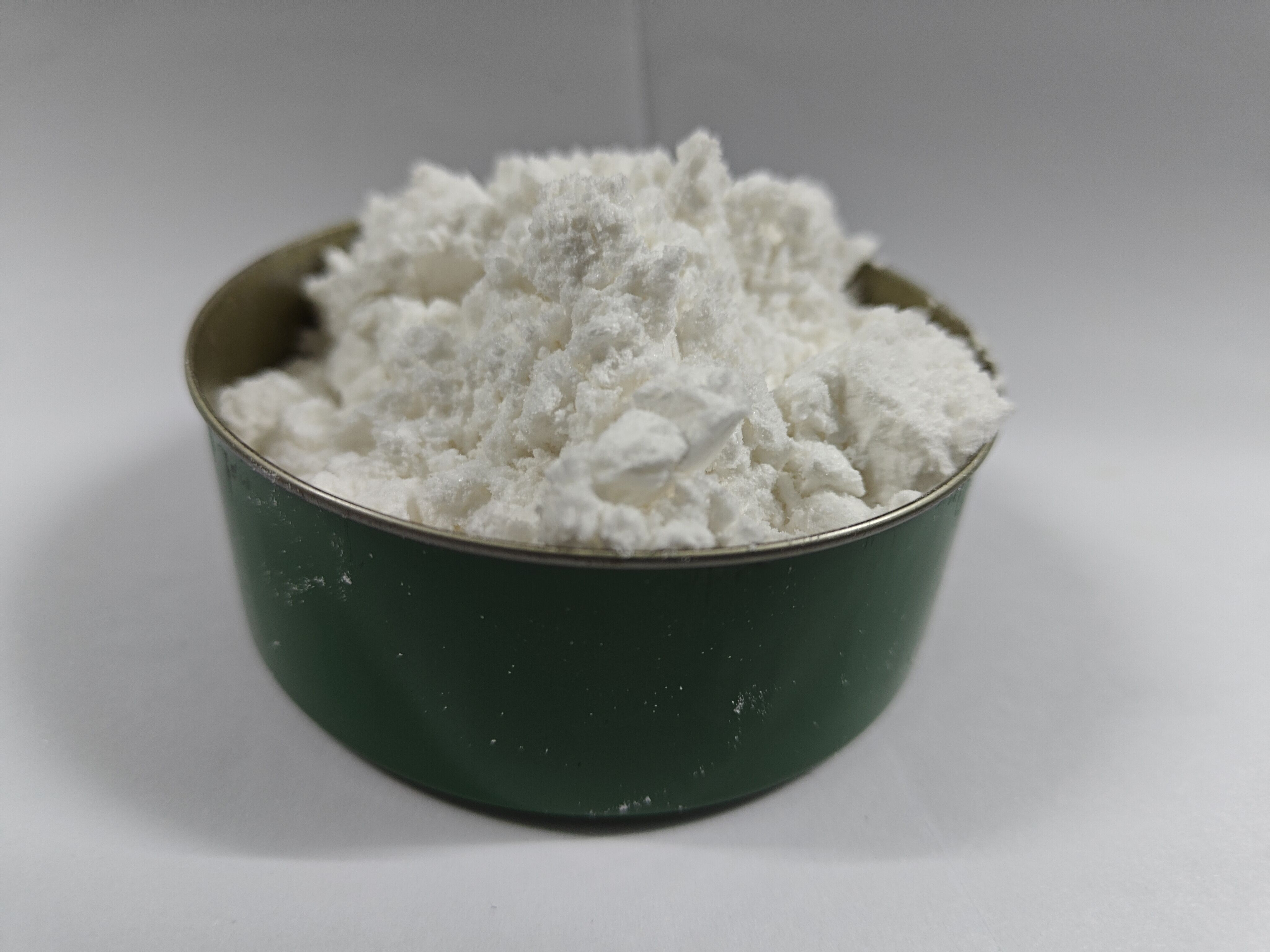

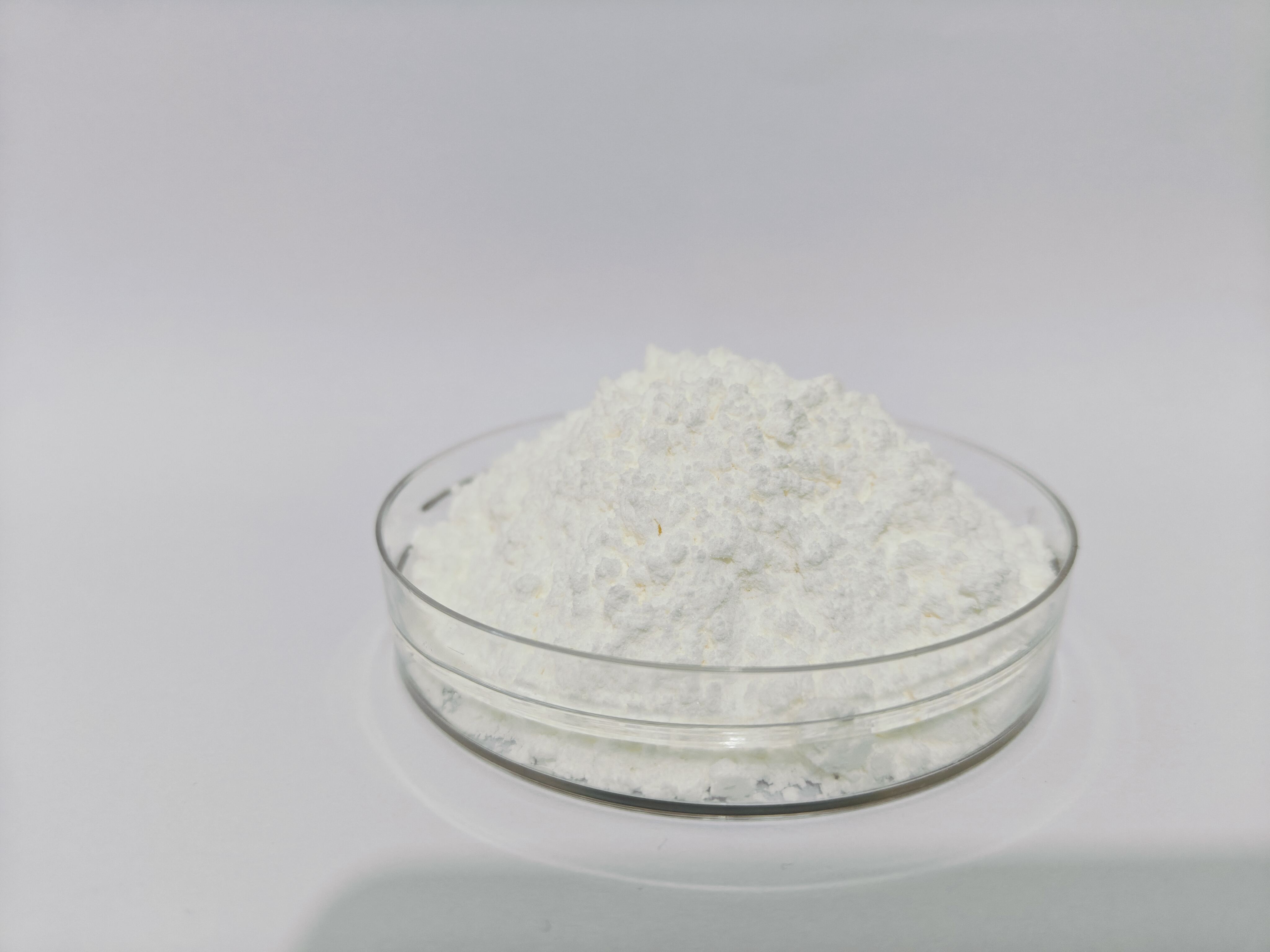

Οι θερμικά υποχρεωτικοί καταλύτες αποτελούν μια επαναστατική πρόοδο στην τεχνολογία χημικής επεξεργασίας της σύγχρονης εποχής. Αυτοί οι πιο εξελιγμένοι καταλύτες παραμένουν αδρανείς στην θερμοκρασία του δωματίου, αλλά ενεργοποιούνται με ακρίβεια όταν εκτίθενται σε συγκεκριμένα οριακά επίπεδα θερμοκρασίας. Αυτή η μοναδική ιδιότητα επιτρέπει βελτιωμένο έλεγχο των χημικών αντιδράσεων και αύξηση της αποδοτικότητας της επεξεργασίας. Η τελευταία γενιά θερμικά υποχρεωτικών καταλύτων ενσωματώνει προηγμένες αρχές σχεδιασμού μορίων, με θερμοαισθητά κλειδώματα που προσωρινά κρύβουν τα ενεργά καταλυτικά σημεία. Όταν ζεσταίνονται σε προορισμένες θερμοκρασίες, αυτά τα κλειδώματα αποσυνδέονται, αποκαλύπτοντας τα ενεργά καταλυτικά σημεία και εκκινώντας τις επιθυμητές χημικές αντιδράσεις. Αυτόν ο έλεγχος της ενεργοποίησης αποδεικνύεται ειδικά αξιόλογος σε εφαρμογές όπως η σκληροποίηση πολυμερών, οι τεχνολογίες καλύψεων και τα συστήματα κολλών. Οι νεότερες εκδοχές εμφανίζουν εκπληκτική σταθερότητα κατά την αποθήκευση, ακριβείς θερμοκρασίες ενεργοποίησης και άριστη καταλυτική απόδοση. Αυτοί οι καταλύτες αποτελούν επιτυχία στις βιομηχανικές και ειδικές εφαρμογές, προσφέροντας απροσδόκητο έλεγχο της χρονικής στιγμής των αντιδράσεων και βελτιωμένη ποιότητα των τελικών προϊόντων. Η ικανότητά τους να επιτρέπουν μονο-συστατικά συστήματα εξαφανίζει την ανάγκη περίπλοκων διαδικασιών αναμιξης, απλοποιώντας έτσι τις επιχειρησιακές διαδικασίες και μειώνοντας τις πιθανές λάθη.