Fundamentals of Epoxy Molding Compounds (EMC)

Composition and Structure of EMC

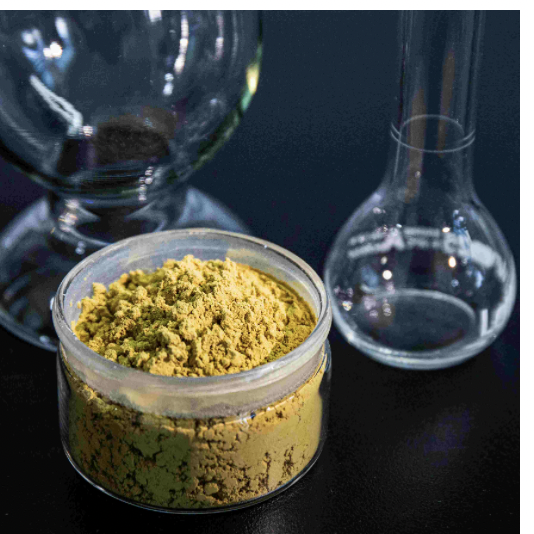

In semiconductor packaging, epoxy molding compounds (EMC) play a critical role by acting as protective coatings for sensitive components. These compounds typically contain four main ingredients: epoxies themselves, hardening agents, filler materials, plus various other additives. The base material comes from epoxy resins which form the primary framework. When mixed with hardeners, they go through a curing process that creates a solid structure. Silica is often used as a filler to boost both heat resistance and mechanical strength. Different additives get thrown into the mix too, each designed to tackle specific issues like fire safety or better sticking properties. What makes EMC so effective for electronics? Well, this particular blend gives it just the right balance of qualities. Epoxy brings flexibility and good bonding capabilities, fillers make sure everything stays rigid and lasts longer, while those hardeners lock everything together creating both structural strength and thermal stability that meets industry standards.

Thermal and Mechanical Requirements for Semiconductor Packaging

When working with semiconductors, the materials used must meet pretty tough thermal demands. They need good thermal conductivity so they can get rid of heat properly while keeping things stable at different temperatures. If an EMC handles heat well, it stops components from getting too hot, which means they last longer overall. Mechanical aspects matter just as much though. The material has to be strong enough without being brittle, flexible when needed, and able to take impacts during handling and actual use. Most manufacturers follow guidelines set by organizations like IPC/JEDEC because those standards specify exactly what properties materials should have for reliable performance in all sorts of situations. These specs aren't just theoretical either they reflect real world challenges faced daily in semiconductor manufacturing. All told, finding the right balance between thermal and mechanical properties remains critical for protecting delicate semiconductor parts through their entire lifecycle.

Chemical Mechanisms of EMC Curing Catalysts

Accelerating Epoxy-Amine Crosslinking Reactions

Crosslinking between epoxy and amine molecules forms the basis of how epoxy molding compounds (EMCs) cure, making them essential for semiconductor packaging applications. When manufacturers add curing catalysts to the mix, they're essentially giving the chemical reaction a boost by reducing the energy barrier that normally slows things down, which means faster curing times overall. What these catalysts do is create an easier path for the reaction to follow, requiring less energy input from the system. Industry data shows certain catalyst types can really speed up these reactions without compromising quality. A study from the Journal of Coatings Technology looked at amine-based catalysts specifically and found they cut curing time dramatically while keeping those all-important thermal characteristics intact. Beyond just saving time on production lines, proper catalysis actually makes the finished products more durable under heat stress and gives them better structural integrity too.

Activation Energy Reduction Strategies

Getting the EMC curing process right starts with picking the right catalyst and making smart formulation changes to cut down on activation energy requirements. Catalyst selection really matters because it determines how fast and efficiently things cure. Take temperature-sensitive catalysts for instance these let manufacturers fine tune the curing process according to whatever thermal conditions exist during production, giving better control over reactions at different temps. Most experienced chemists look at things like material compatibility and how hot things need to get before the catalyst kicks in when choosing their options. A recent paper showed some pretty impressive results from labs testing different catalyst mixtures, with reaction rates jumping by significant margins when proper combinations were used. Beyond speeding things up, these tweaks help maintain those critical thermal and mechanical characteristics needed for serious applications where reliability counts, especially in industries like semiconductor packaging where even small variations can cause major problems downstream.

Types and Functions of EMC Curing Catalysts

Imidazole Derivatives for Precision Cure Control

Imidazole derivatives are really important for getting just the right cure control in those EMC formulations. What makes these compounds special is how their molecular makeup affects both catalytic efficiency and how reactions actually happen. They speed things up quite a bit during epoxy curing because they basically cut down on what's called activation energy. For anyone working with stuff that needs exact cure timing, like making circuit boards or working with advanced composites, these additives become pretty much essential. Take a look at industries where getting things right matters most, say aerospace or automotive manufacturing. These sectors rely heavily on imidazoles to maintain product quality across all those demanding specifications where even small variations can cause big problems later on.

Quinone-Based Systems for High-Temperature Stability

Quinone based curing systems really shine when it comes to handling extreme heat, which makes them perfect for harsh environments. What sets these apart is how they keep their strength and stickiness even when things get pretty rough. Think about places like spacecraft manufacturing or heavy machinery parts that need protection from intense conditions. The resilience factor means these coatings last much longer than alternatives exposed to high temps day after day. Lab tests over recent years show pretty consistent outcomes across different batches, something manufacturers care deeply about since temperature resistance matters so much in certain sectors. Field trials specifically point to good performance in maintaining electrical insulation properties during tough operations, proving why many factories continue choosing quinone systems despite higher upfront costs.

Impact of Catalysts on EMC Performance

Tuning Glass Transition Temperature (Tg)

Knowing how catalysts affect the glass transition temperature (Tg) makes all the difference when trying to get the most out of EMC materials. The Tg point marks where EMC starts changing its behavior as it heats up, especially regarding how much it expands and its stiffness characteristics. Manufacturers play around with different catalysts to tweak these Tg properties so they match what the application needs in terms of heat resistance. Take epoxy mold compounds for example many companies have developed special catalyst blends that let them boost Tg without needing crazy high cure temps during production. I remember reading about one manufacturer who changed their catalyst mix and saw dramatic improvements in their EMC's heat handling capabilities. This kind of adjustment matters a lot in industries where components need to withstand varying temperature conditions over time.

Balancing Cure Speed vs. Process Window Flexibility

Selecting the right EMC curing catalyst usually means walking a tightrope between how fast things cure and how flexible the process window needs to be. Faster curing definitely boosts production speeds, but it can really restrict what manufacturers can do when conditions change on the factory floor. Finding this sweet spot comes down to picking catalysts that work well for each particular manufacturing situation. From what I've seen in some research papers, going with catalysts that react a bit slower actually gives wider process windows, which means factories can handle all sorts of different conditions without totally sacrificing those precious minutes saved by quick curing. Most seasoned professionals suggest looking at both what the production line needs and how the catalyst performs under test conditions before making a decision. This helps strike that balance between getting products out the door quickly while still maintaining enough flexibility to deal with real world manufacturing challenges.

Catalyst Selection for Advanced Semiconductor Packaging

Moisture Resistance and MSL Compliance Considerations

Keeping moisture at bay remains a key concern for semiconductor packaging since water damage can seriously impact how well electronic devices perform over time. Epoxy Molding Compounds (EMCs) with proper curing catalysts make a big difference here by creating barriers against moisture that would otherwise eat away at sensitive components inside chips. For Moisture Sensitivity Level (MSL) requirements, getting the catalyst selection right becomes absolutely essential. Different catalyst formulations affect how well packages hold up under various humidity conditions, which matters a lot when these products end up in environments where temperature fluctuations are common. Looking at what manufacturers are seeing across the board, there's clear evidence showing that better moisture protection isn't just nice to have anymore it's becoming standard practice as companies strive to extend the lifespan of their semiconductor products while meeting tougher quality specifications from customers who demand longer lasting electronics.

Halogen-Free Catalyst Systems for Eco-Compliance

The semiconductor sector has seen rising interest in eco-friendly materials lately, especially those free from halogens. These types of catalysts cut down on dangerous chemicals found in electronics while keeping pace with international regulations. For manufacturers, this change helps them stay compliant with environmental rules and shows they care about green practices. Research indicates that moving to halogen-free options reduces harm to ecosystems and makes it easier to recycle old gadgets. With governments across the globe cracking down harder on toxic substances in manufacturing, going halogen-free isn't just good for the planet anymore it's becoming essential for staying within legal boundaries too.

Innovations in Catalyzed EMC Technologies

Nanoparticle-Enhanced Catalytic Efficiency

Nanoparticles are changing the game when it comes to making EMC curing catalysts work better. Their special shape and huge surface area really speed up reactions and give better results overall. This means the curing process happens faster and completes more thoroughly. Material scientists have been looking into this stuff lately and found that adding nanoparticles actually makes epoxy molding compounds (EMC) stronger against heat, chemicals, and physical stress. The field of materials research keeps coming up with new tricks like this, which helps manufacturers produce semiconductors more efficiently while getting better performance from their products. Semiconductor companies around the world are starting to adopt nanoparticle technology because it looks like a must-have component for advancing EMC tech in the years ahead.

Dual-Catalyst Synergy for Multi-Stage Curing

Using dual catalyst systems offers a solid way to handle multi stage curing processes since they mix different catalysts together which creates some pretty good synergies that boost how well things work overall. The beauty of this method is it lets manufacturers fine tune their curing profiles so they can actually process a wider variety of materials than before. When companies implement these dual catalyst approaches, they gain control over each stage of the curing process allowing them to get exactly the right balance between material characteristics and how fast everything sets. We see this happening all the time in industries like high precision electronics manufacturing and automotive parts production where dual catalyst applications have proven themselves time and again. Products made with this technique show better thermal stability under stress tests and maintain stronger mechanical integrity even after extended use. Beyond just making better products, these systems help factories run smoother operations while delivering end results that last longer and perform better in real world conditions.

Smart Catalysts for Self-Regulating Cure Profiles

The latest smart catalyst technology is changing how EMC applications work, thanks to their ability to create self-regulating cure profiles that respond to different environmental conditions. What makes these catalysts special is their built-in systems that tweak the curing process according to temperature changes, humidity levels, and other outside influences. This means manufacturers don't need constant hands-on monitoring anymore. Take semiconductor packaging for example when workshop temperatures swing up and down throughout the day. Smart catalysts keep the curing rate steady so the final product stays intact. Real world tests show better results across the board from fewer defects to more consistent quality. The numbers back this up too many factories report cutting down on material waste by around 30% while still meeting strict production standards. Plus, these smarter materials help cut down on energy consumption which matters a lot in today's market where green manufacturing isn't just nice to have it's becoming essential for staying competitive.

Frequently Asked Questions

What are Epoxy Molding Compounds (EMC) used for?

Epoxy molding compounds are used for semiconductor packaging as they provide encapsulation and protection for delicate components against thermal and mechanical stress.

How does EMC improve semiconductor packaging?

EMC contributes to semiconductor packaging by enhancing thermal management, providing mechanical strength, and ensuring durability, which collectively extend the life of electronic components.

What role do catalysts play in the curing of EMC?

Catalysts reduce the activation energy in the epoxy-amine crosslinking process, accelerating curing times and improving thermal stability and mechanical strength of EMC.

What are the benefits of using imidazole derivatives in EMC formulations?

Imidazole derivatives enhance catalytic efficiency, allowing for precise cure control, which is crucial in high-spec applications like aerospace and automotive industries.

Why are halogen-free catalyst systems important?

Halogen-free catalyst systems help reduce hazardous substances in electronic products, supporting eco-compliance and sustainability initiatives in line with global regulatory standards.