Procurement teams in pharmaceutical and biotechnology companies face a complex decision when selecting suppliers for specialized chemical reagents. The evaluation of cdi coupling reagent suppliers requires a comprehensive understanding of product specifications, supplier reliability, and cost-effectiveness. These critical chemical compounds serve as essential building blocks in drug development and research applications, making supplier selection a strategic decision that impacts both project timelines and budget allocations.

The procurement process for cdi coupling reagent involves multiple stakeholders, including research scientists, quality assurance teams, and supply chain managers. Each group brings unique perspectives on supplier evaluation criteria, from technical specifications to regulatory compliance requirements. Understanding these diverse needs enables procurement professionals to develop comprehensive supplier assessment frameworks that balance scientific requirements with commercial considerations.

Understanding CDI Coupling Reagent Applications

Chemical Properties and Reaction Mechanisms

CDI coupling reagents function as carbonylating agents in organic synthesis, facilitating the formation of amide bonds, esters, and other carbonyl-containing compounds. The reagent's high reactivity and selectivity make it particularly valuable in pharmaceutical synthesis where precise control over reaction conditions is essential. Research laboratories utilize cdi coupling reagent in medicinal chemistry programs, where the formation of stable amide linkages is crucial for drug candidate development.

The mechanism of action involves the activation of carboxylic acids through the formation of acylimidazole intermediates. This activation step significantly enhances the electrophilicity of the carbonyl carbon, enabling efficient nucleophilic attack by amines or other nucleophiles. The resulting products maintain high purity levels, which is critical for downstream applications in pharmaceutical development processes.

Industrial Applications and Market Demand

Manufacturing facilities across the pharmaceutical industry rely on consistent supplies of high-quality cdi coupling reagent for large-scale synthesis operations. The compound's stability under various storage conditions and its compatibility with diverse organic solvents make it suitable for automated manufacturing processes. Process development teams often specify particular grades or purities based on their specific synthesis requirements and final product specifications.

The growing demand for personalized medicines and specialty pharmaceuticals has increased the need for versatile coupling reagents. Contract manufacturing organizations particularly value suppliers who can provide flexible packaging options and customized delivery schedules to support varying production volumes. This market dynamic influences how procurement teams evaluate potential suppliers and structure their supply agreements.

Supplier Evaluation Criteria

Product Quality and Consistency Standards

Quality assessment begins with comprehensive evaluation of analytical certificates and batch-to-batch consistency data. Procurement teams examine suppliers' quality control systems, including analytical testing protocols, stability studies, and contamination control measures. The reliability of cdi coupling reagent performance directly impacts research outcomes and manufacturing efficiency, making quality consistency a primary evaluation criterion.

Suppliers who maintain rigorous quality management systems demonstrate their commitment to consistent product delivery. This includes documentation of manufacturing processes, environmental controls, and personnel training programs. Advanced analytical capabilities, such as nuclear magnetic resonance spectroscopy and mass spectrometry, indicate a supplier's ability to provide detailed product characterization and support troubleshooting efforts when needed.

Regulatory Compliance and Documentation

Regulatory compliance requirements vary significantly across different geographic markets and application areas. Suppliers must provide comprehensive documentation packages that include safety data sheets, certificates of analysis, and regulatory status information. For pharmaceutical applications, additional documentation may include drug master files or letters of access for regulatory submissions.

Environmental, health, and safety compliance represents another critical evaluation dimension. Procurement teams assess suppliers' environmental management systems, waste handling procedures, and worker safety programs. These factors become increasingly important as companies strengthen their sustainability commitments and supply chain responsibility initiatives.

Cost Analysis and Value Assessment

Total Cost of Ownership Calculations

Effective cost analysis extends beyond unit pricing to encompass total cost of ownership considerations. This includes transportation costs, inventory carrying costs, and potential costs associated with supply disruptions. The stability characteristics of cdi coupling reagent influence storage requirements and shelf-life considerations, which impact inventory management strategies and associated costs.

Volume-based pricing structures often provide opportunities for cost optimization, particularly for organizations with predictable consumption patterns. However, procurement teams must balance volume commitments against inventory risks and changing research priorities. Long-term supply agreements may offer price stability but require careful consideration of demand forecasting accuracy and supplier performance reliability.

Value-Added Services and Support

Technical support capabilities distinguish premium suppliers from commodity providers in the cdi coupling reagent market. This includes access to application specialists, analytical support services, and custom synthesis capabilities. Suppliers who offer comprehensive technical documentation, including reaction protocols and troubleshooting guides, provide additional value to research and development teams.

Logistics and supply chain services represent another dimension of supplier value assessment. Flexible packaging options, expedited shipping capabilities, and inventory management programs can significantly impact operational efficiency. Some suppliers offer consignment inventory arrangements or vendor-managed inventory programs that reduce working capital requirements and improve supply security.

Risk Management and Supply Security

Supply Chain Resilience Evaluation

Supply chain risk assessment examines suppliers' manufacturing capabilities, geographic distribution, and business continuity planning. Single-source dependencies create significant risks for critical reagents like cdi coupling reagent, particularly when supporting time-sensitive research projects or manufacturing commitments. Diversified supplier networks provide greater supply security but require careful coordination to maintain quality consistency.

Suppliers' financial stability and business continuity plans deserve careful evaluation, especially for specialized chemical manufacturers. This assessment includes review of financial statements, insurance coverage, and disaster recovery procedures. The COVID-19 pandemic highlighted the importance of robust business continuity planning and flexible manufacturing capabilities in maintaining supply chain resilience.

Quality Risk Assessment

Quality risks encompass potential variations in product specifications, contamination issues, and regulatory compliance failures. Procurement teams evaluate suppliers' quality systems through audits, third-party certifications, and performance history analysis. The cdi coupling reagent market includes both established manufacturers and emerging suppliers, requiring careful assessment of quality capabilities and track records.

Change control procedures represent a critical aspect of quality risk management. Suppliers must demonstrate robust change management systems that provide advance notification of manufacturing process modifications, facility changes, or raw material sourcing adjustments. These procedures ensure that customers can evaluate the potential impact of changes on their applications and adjust their processes accordingly.

Supplier Relationship Management

Communication and Responsiveness

Effective communication channels facilitate smooth business relationships and rapid issue resolution. Procurement teams evaluate suppliers' responsiveness to inquiries, technical support availability, and escalation procedures for urgent situations. Regular communication regarding inventory levels, delivery schedules, and potential supply constraints enables proactive supply chain management.

Technology platforms that provide real-time visibility into order status, inventory levels, and quality data enhance operational efficiency. Suppliers who invest in customer-facing technology demonstrate their commitment to service excellence and operational transparency. These capabilities become particularly valuable for organizations managing multiple concurrent projects with varying supply requirements.

Long-Term Partnership Potential

Strategic supplier relationships extend beyond transactional interactions to encompass collaborative development initiatives and mutual growth opportunities. Suppliers who demonstrate willingness to invest in customer-specific capabilities, such as custom packaging or specialized analytical services, indicate strong partnership potential. These relationships often yield benefits in terms of preferential pricing, priority allocation during supply constraints, and access to new product developments.

Innovation capabilities and research and development investments distinguish forward-thinking suppliers in the cdi coupling reagent market. Suppliers who actively develop improved formulations, enhanced packaging solutions, or novel synthesis methods provide long-term value to their customers. Collaborative research relationships can lead to competitive advantages and improved operational efficiency for both parties.

Technology and Innovation Factors

Manufacturing Technology and Capabilities

Advanced manufacturing technologies enable consistent product quality and efficient production processes. Procurement teams assess suppliers' manufacturing capabilities, including equipment sophistication, process automation, and quality control systems. Modern manufacturing facilities often incorporate continuous improvement methodologies and advanced process control systems that enhance product consistency and reduce variation.

Analytical capabilities represent another dimension of technological assessment. Suppliers with comprehensive analytical laboratories can provide detailed product characterization and support method development activities. Advanced analytical techniques enable early detection of quality issues and support troubleshooting efforts when process variations occur.

Digital Integration and Data Management

Digital integration capabilities facilitate seamless information exchange and improve supply chain transparency. Electronic data interchange systems, application programming interfaces, and cloud-based platforms enable real-time communication and reduce administrative overhead. These technological capabilities become increasingly important as organizations digitize their procurement processes and implement supply chain visibility initiatives.

Data management systems that maintain comprehensive batch records and historical performance data support traceability requirements and quality investigations. Suppliers who maintain robust data management systems can quickly respond to customer inquiries and provide detailed documentation for regulatory submissions or quality audits.

FAQ

What are the most important quality specifications for cdi coupling reagent procurement

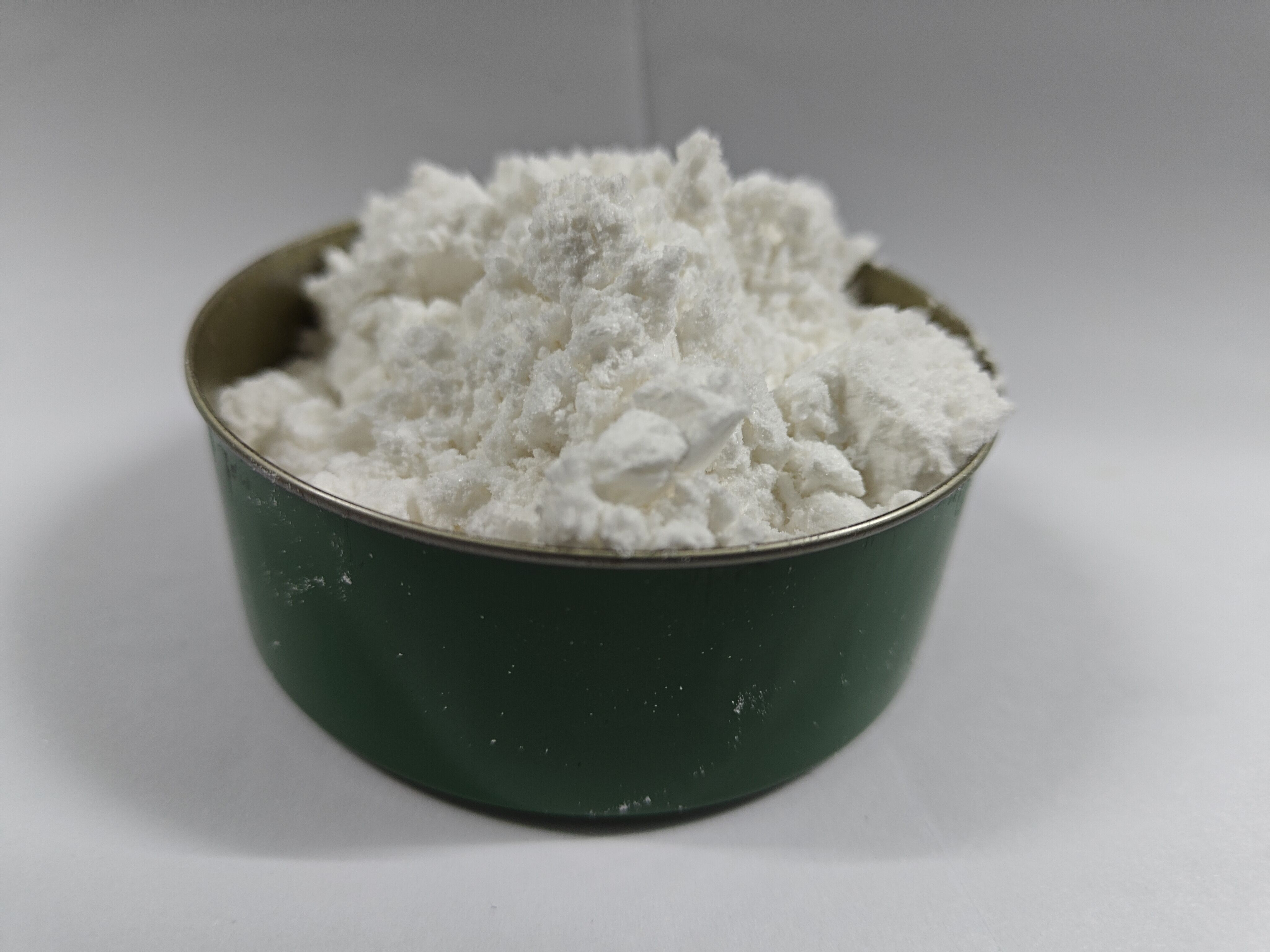

Key quality specifications include purity levels typically exceeding 95%, water content below specified limits, and absence of heavy metal contaminants. Analytical certificates should document these parameters along with identity confirmation through spectroscopic methods. Consistent particle size distribution and bulk density measurements ensure reliable handling characteristics in automated equipment.

How do procurement teams evaluate supplier manufacturing capabilities

Manufacturing capability assessment involves facility audits, review of quality management systems, and evaluation of production capacity and flexibility. Teams examine suppliers' equipment maintenance programs, environmental controls, and personnel training records. Production scheduling capabilities and ability to handle varying order sizes also influence supplier selection decisions for cdi coupling reagent procurement.

What role does geographical location play in supplier selection

Geographic proximity affects transportation costs, delivery times, and supply chain risk exposure. Local or regional suppliers often provide faster response times and lower shipping costs but may have limited production capacity. Global suppliers offer broader capabilities and potentially better pricing but introduce additional logistics complexity and potential supply disruptions from international trade issues.

How important are sustainability considerations in supplier evaluation

Sustainability factors increasingly influence supplier selection as organizations strengthen their environmental commitments. This includes evaluation of suppliers' waste management practices, energy efficiency initiatives, and carbon footprint reduction programs. Suppliers who demonstrate environmental responsibility and social compliance often receive preference in competitive sourcing decisions, particularly for large-volume cdi coupling reagent requirements.