цени на агенти за оттвърдване на епоксидни смоли

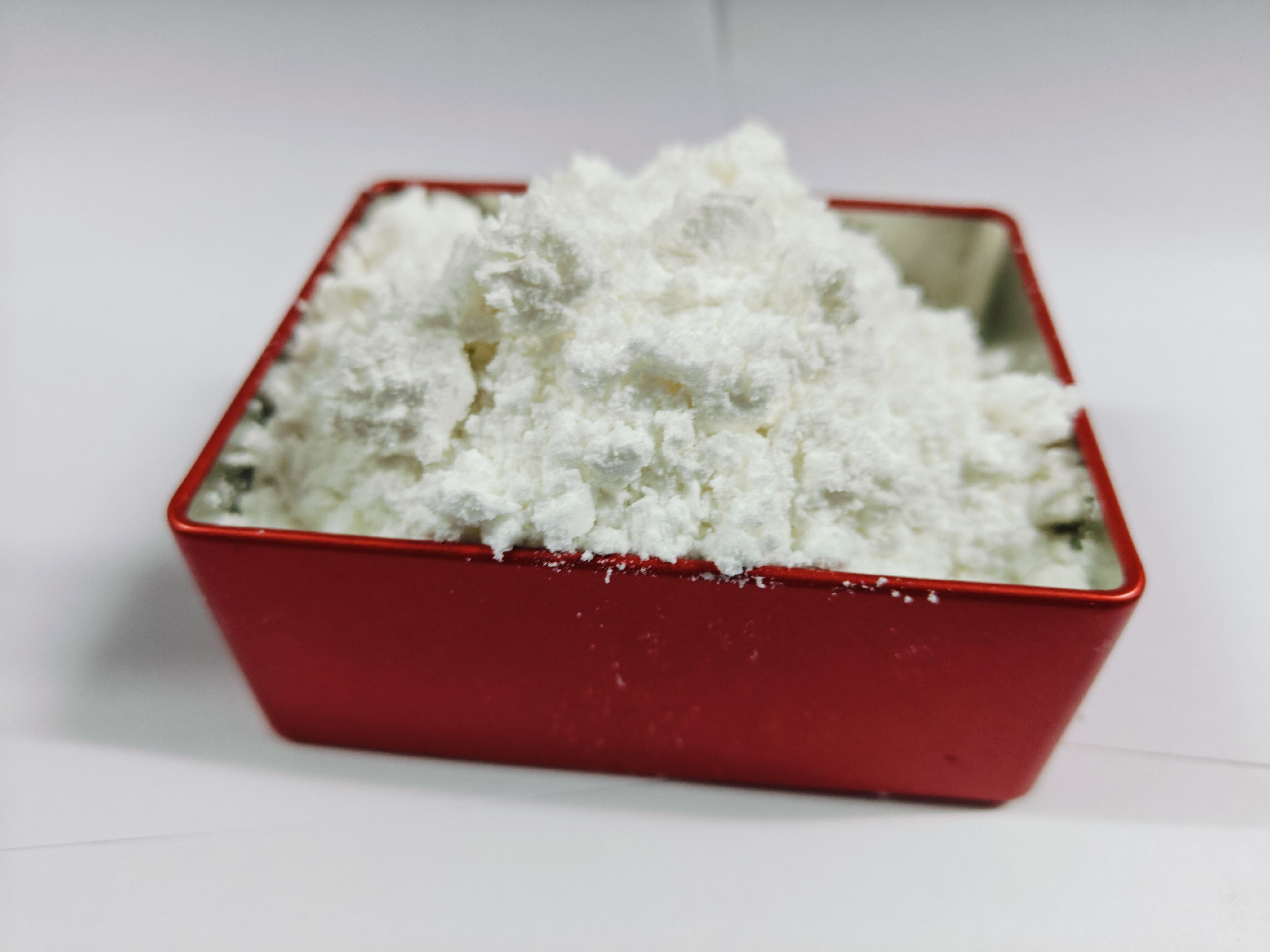

Цените на агенти за твърдяване на епоксидни смоли отразяват сложното взаимодействие между пазарните динамики и производствените процеси в индустрията на клеовете. Тези основни компоненти играят критична роля при преобразуването на течните епоксидни смоли в издръжливи, кръстосани полимери. Структурата на цените обикновено се променя по няколко фактора, включително цените на суровините, мащаба на производството и пазарната заявка. Агентите за твърдяване с висока производителност, които предлагат подобрена химична устойчивост и термична стабилност, обикновено имат по-високи цени поради технически сложните им формулиращи процеси. Пазарът наблюдава вариации в цените сред различните видове, от аминобазирани агенти за твърдяване до полиамиди и анхидриди, всеки от които предлага специфични характеристики при твърдяването и производителност. Промишлените агенти за твърдяване, използвани в строителството и автомобилната промишленост, често имат различни ценови точки спрямо онези, които се използват в специални приложения като авиационната или електрониката. Глобалните динамики на ланцуга на доставки, включително наличността на суровините и разходите за транспорт, значително влияят върху крайната цена. Производителите често предлагат различни опции за упаковка, от големи количества за индустриални потребители до по-малки единици за специализирани приложения, с коректиране на цените, отразяващи тези разлики в обем и изисквания за упаковка.