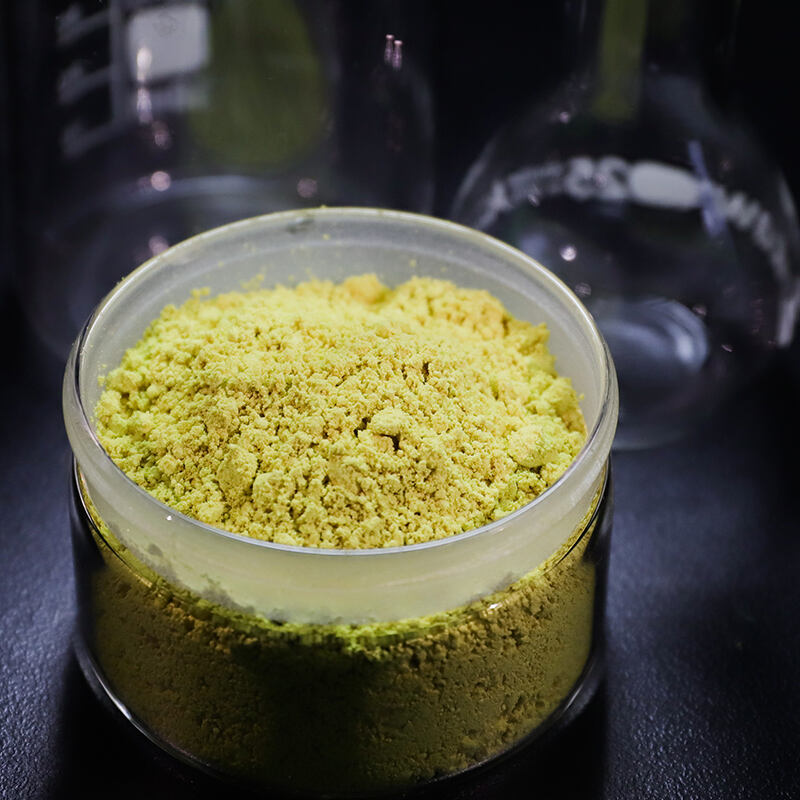

high quality tptpbq

The high quality tptpbq represents a significant advancement in industrial machinery technology, combining innovative engineering with practical functionality. This robust system features state of the art precision control mechanisms that ensure consistent performance across various applications. At its core, the tptpbq utilizes advanced servo motors coupled with intelligent feedback systems, enabling real time adjustments and optimal operation parameters. The machine's modular design allows for easy customization and upgrades, making it adaptable to diverse industrial requirements. With its integrated digital interface, operators can monitor and adjust performance metrics through an intuitive dashboard. The tptpbq excels in maintaining operational efficiency through its automated maintenance alerts and predictive diagnostics features. Its reinforced framework ensures durability while specialized coating protects against environmental factors. The system's energy efficient operation aligns with modern sustainability requirements, while its compact footprint maximizes space utilization in industrial settings. Advanced safety features include emergency shutdown protocols and operator protection systems, meeting all current industry standards.