emc curing kinetics

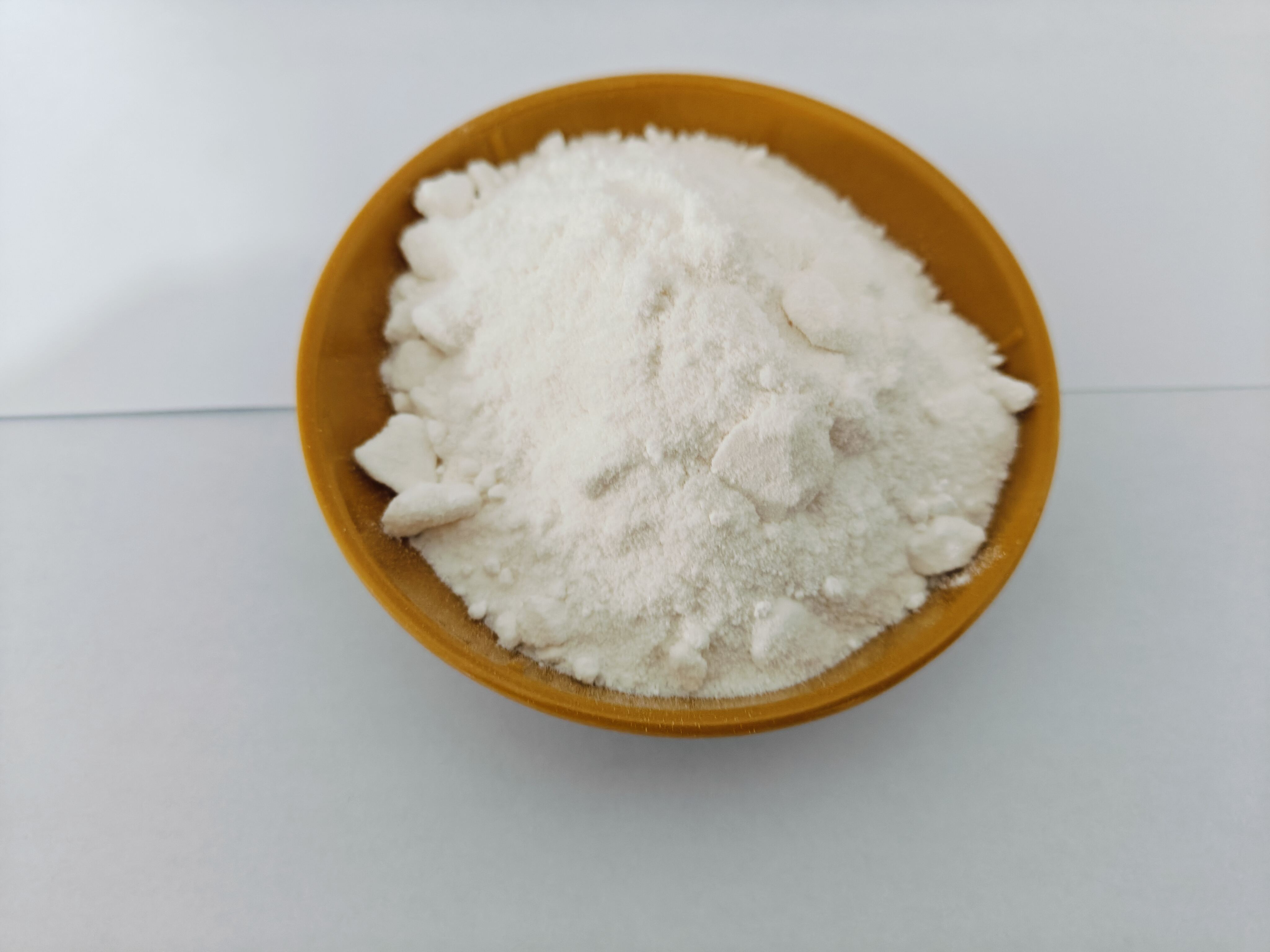

EMC curing kinetics refers to the study and analysis of the chemical reaction processes that occur during the curing of epoxy molding compounds. This scientific approach examines the rate of reaction, temperature dependence, and conversion characteristics that determine the final properties of the cured material. The process involves sophisticated monitoring of cross-linking reactions, which are crucial for achieving optimal mechanical and electrical properties in electronic packaging applications. EMC curing kinetics plays a vital role in semiconductor packaging, where precise control of the curing process ensures reliable encapsulation of electronic components. The technology employs various analytical methods, including differential scanning calorimetry and dynamic mechanical analysis, to understand and optimize the curing behavior. These methods help determine critical parameters such as activation energy, reaction order, and cure degree, which are essential for developing efficient manufacturing processes. The application of EMC curing kinetics extends to quality control, process optimization, and product development in the electronics manufacturing industry, ensuring consistent and reliable protection for sensitive electronic components.