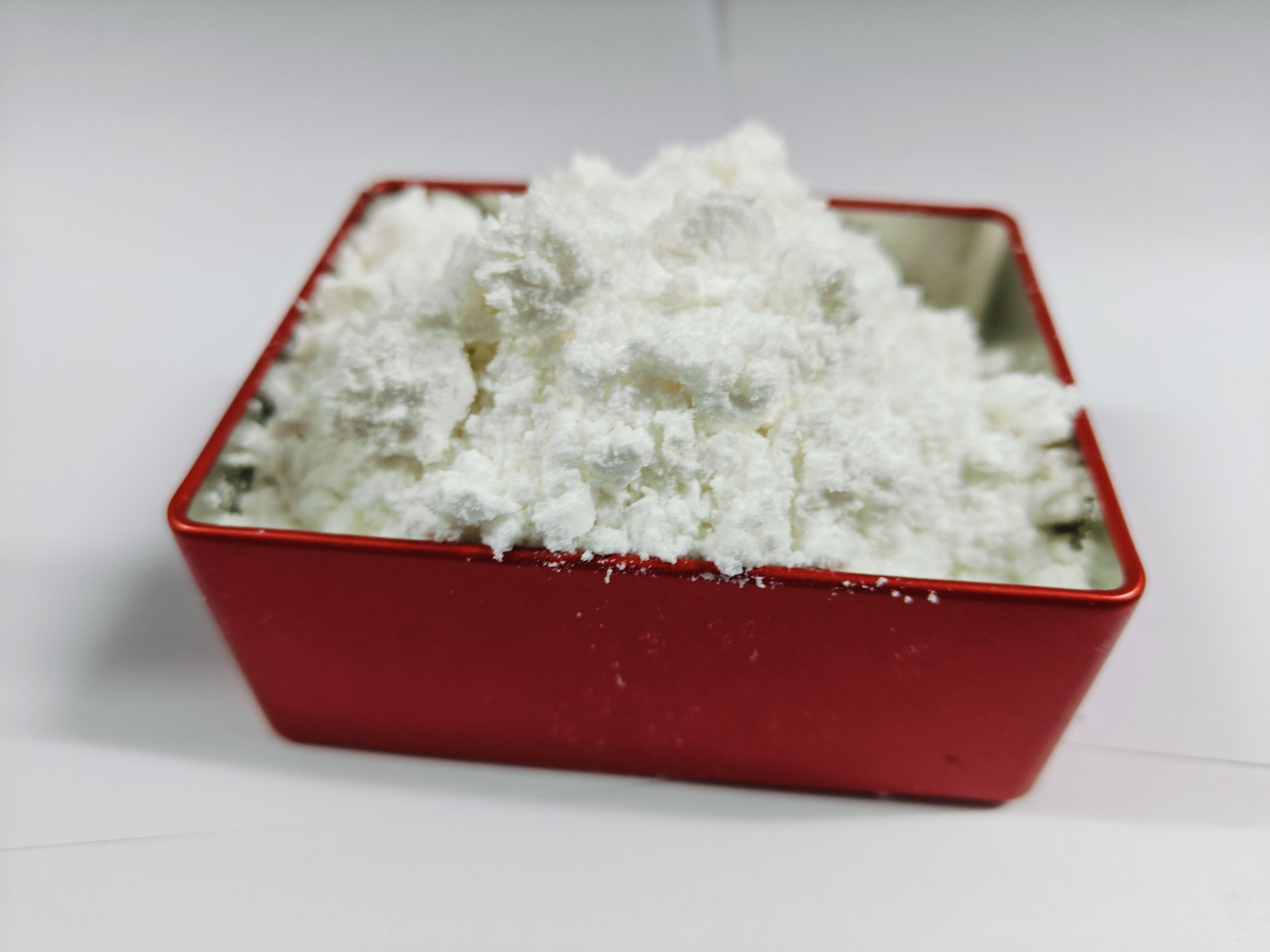

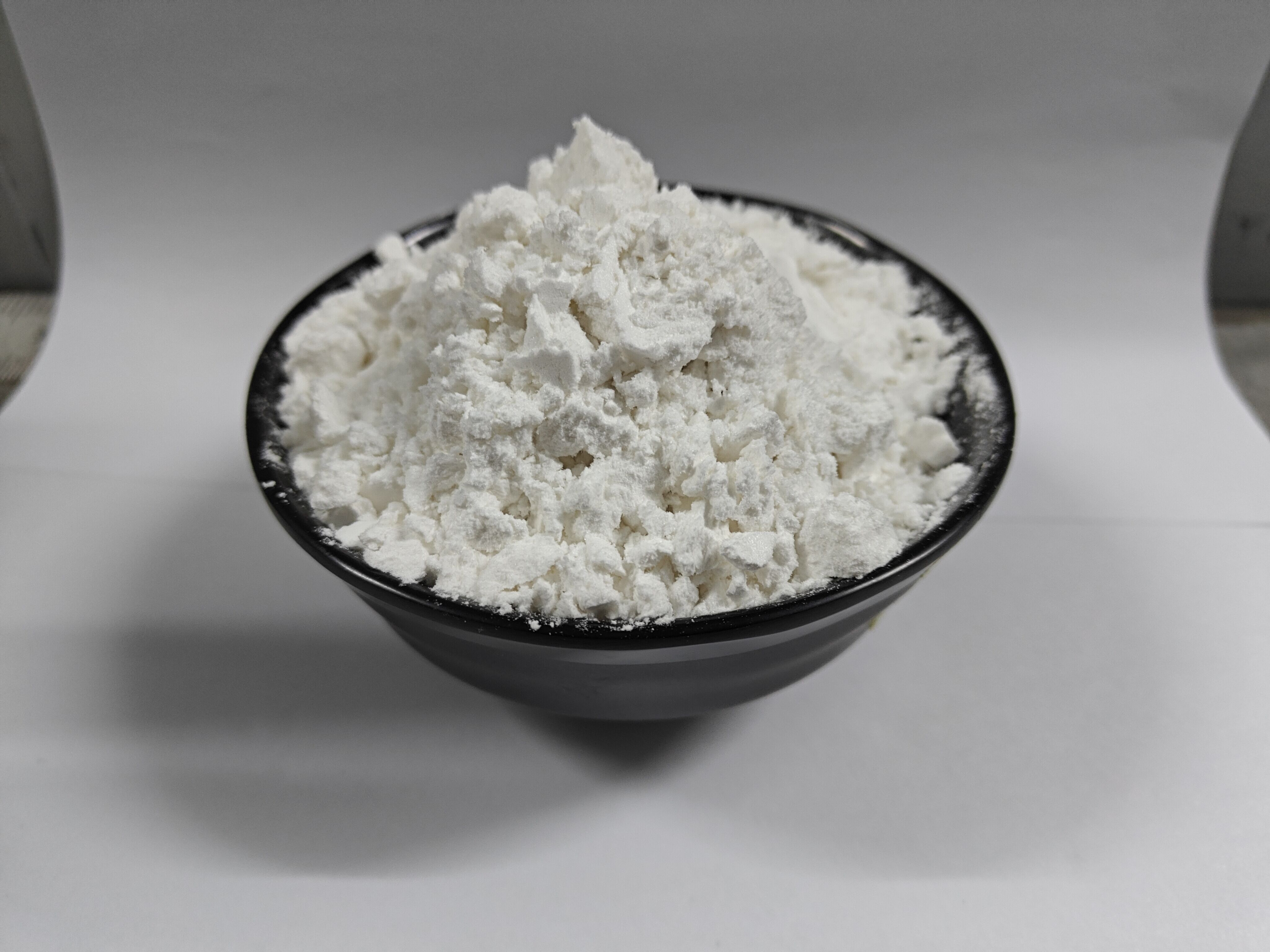

cdi reagent manufacturer

A CDI reagent manufacturer specializes in the production of carbonyldiimidazole (CDI) and related compounds essential for pharmaceutical and chemical synthesis. These manufacturers employ advanced production techniques and quality control measures to ensure the highest purity levels and consistency in their products. The facilities typically feature state-of-the-art manufacturing equipment, including precision temperature control systems, advanced filtration processes, and sophisticated analytical instruments for quality assurance. They maintain strict compliance with international manufacturing standards and good manufacturing practices (GMP). The production process involves careful handling of raw materials, controlled reaction conditions, and thorough purification steps to achieve optimal product quality. These manufacturers often provide custom synthesis services, technical support, and documentation to meet specific customer requirements. Their expertise extends to developing innovative synthetic routes and optimizing production processes to enhance efficiency and reduce costs. The manufacturing facilities are equipped with environmental control systems and safety measures to ensure worker safety and environmental protection. Quality control laboratories perform comprehensive testing at various production stages to verify product specifications and maintain batch-to-batch consistency.