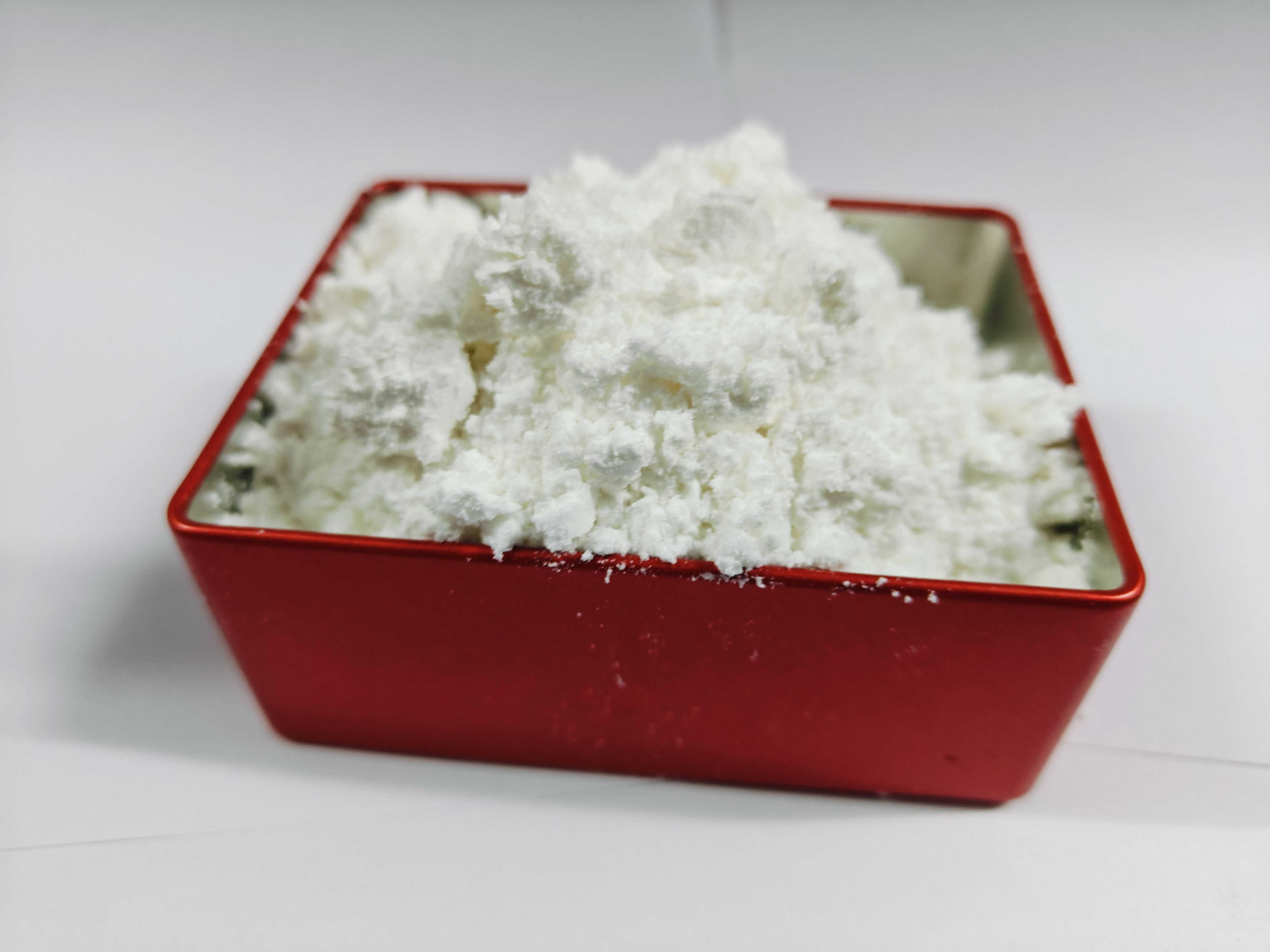

kimikal na reaksyon ng tppbq

Ang mga reaksyon kimikal ng TPPBQ (Tetraphenylphosphonium Bromide Quinone) ay kinakatawan bilang isang malaking pag-unlad sa sintesis organiko at katalisis. Kinikailangan ng mga reaksyon ito ang unikong interaksiyon sa pagitan ng tetraphenylphosphonium bromide at mga deribatibo ng quinone, nagbubuo ng mga tagapagkuha na maayos para sa iba't ibang proseso kimikal. Ang mekanismo ng reaksyon ay pangunahing gumagana sa pamamagitan ng mga proseso ng pagsisiyasat ng elektro, pinapagana ang mga landas ng pag-oxidize at pag-reduce na may piling. Sa mga aplikasyon ng laboratorio, ipinapakita ng mga reaksyon ng TPPBQ na may higit na estabilidad at reproduktibilidad sa ilalim ng mga standard na kondisyon, nagiging mahalaga sila ba sa pananaliksik at industriyal na layunin. Ang teknolohiya ay may presisong kontrol sa mekanika ng reaksyon, nagpapahintulot ng optimisadong bunga at piling ng produkto. Nakikitang may maraming gamit ang mga reaksyon ito sa sintesis ng farmaseutikal, lalo na sa produksyon ng mga komplikadong molekula organiko at aktibong mga ingredyente ng farmaseutikal. Nagpapakita din ang proseso ng kamangha-manghang talino sa siyensya ng mga anyo, nagdidiskubre sa pag-unlad ng mga advanced polymers at functional materials. Ang mga modernong implementasyon ng mga reaksyon ng TPPBQ ay naiimbento mula sa pinagaling na kakayahan sa pagsusuri at automatikong sistema ng kontrol, siguradong magiging konsistente ang mga resulta sa iba't ibang antas ng operasyon.