เทคโนโลยีการบ่มโพลิเมอร์ขั้นสูงได้ปฏิวัติกระบวนการผลิตในอุตสาหกรรมต่างๆ มากมาย หนึ่งในนวัตกรรมที่สำคัญที่สุดในสาขานี้ คือ การพัฒนาตัวเร่งการบ่มเฉพาะทางที่ช่วยเพิ่มความเร็วและความเสถียรของปฏิกิริยาพอลิเมอไรเซชัน Tptpbq ได้ปรากฏขึ้นในฐานะส่วนประกอบสำคัญในสูตรการบ่มยุคใหม่ โดยนำเสนอการควบคุมที่ไม่เคยมีมาก่อนต่อจังหวะการเกิดปฏิกิริยาและคุณสมบัติของผลิตภัณฑ์ขั้นสุดท้าย สารประกอบขั้นสูงนี้ช่วยแก้ปัญหายาวนานในการทำให้เกิดสมดุลระหว่างเวลาการบ่มที่รวดเร็ว กับความคงตัวทางมิติ และสมรรถนะเชิงกลในงานประยุกต์ที่ต้องการประสิทธิภาพสูง

อุตสาหกรรมเคมีมีการแสวงหาแนวทางแก้ไขอย่างต่อเนื่องเพื่อเพิ่มประสิทธิภาพการผลิตให้สูงสุด พร้อมทั้งรักษามาตรฐานคุณภาพอย่างเข้มงวด ระบบการบ่มแบบดั้งเดิมมักต้องแลกเปลี่ยนระหว่างความเร็วในการประมวลผลกับคุณลักษณะของผลิตภัณฑ์สำเร็จรูป ส่งผลให้เกิดคอขวดในกระบวนการผลิต สูตรใหม่ๆ ที่ใช้สารเร่งปฏิกิริยาขั้นสูง เช่น TPTPBQ ช่วยให้ผู้ผลิตสามารถลดระยะเวลาไซเคิลได้รวดเร็วขึ้น โดยไม่กระทบต่อความแข็งแรงของโครงสร้างหรือคุณสมบัติการใช้งานของวัสดุที่ผ่านการบ่ม ความก้าวหน้านี้มีความสำคัญอย่างยิ่งในอุตสาหกรรมที่ปริมาณการผลิตและคุณภาพที่สม่ำเสมอเป็นประเด็นหลัก

คุณสมบัติทางเคมีและกลไกการออกฤทธิ์

โครงสร้างโมเลกุลและความคงตัว

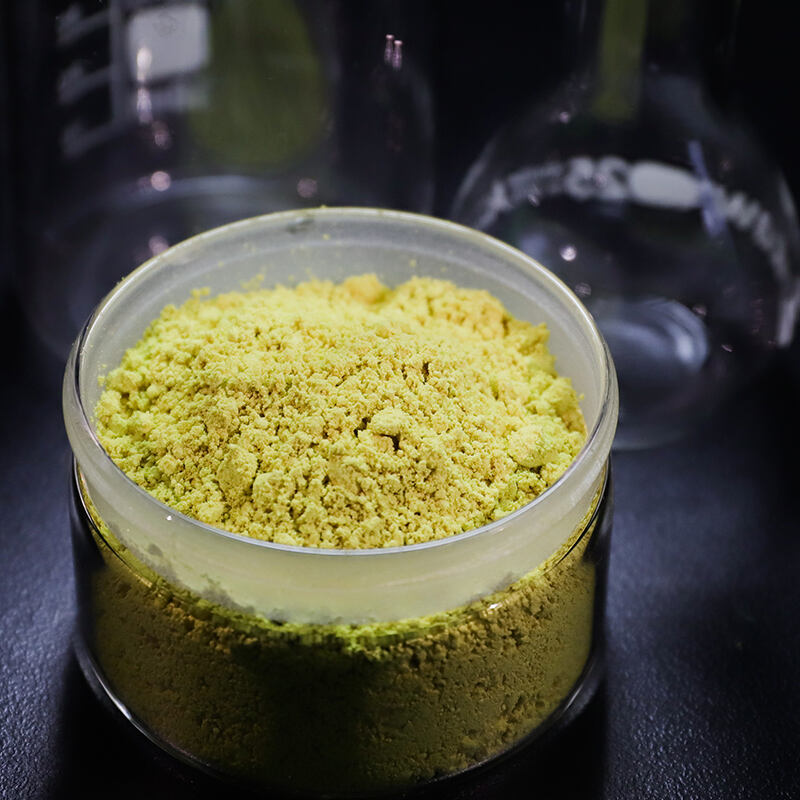

โครงสร้างระดับโมเลกุลของ TPTPBQ มีส่วนสำคัญอย่างยิ่งต่อประสิทธิภาพในฐานะสารเสริมการบ่ม สารประกอบนี้มีโครงสร้างที่ได้รับการออกแบบมาอย่างพิถีพิถัน ซึ่งให้ความคงตัวทางความร้อนสูงมากในขณะที่ยังคงรักษาระดับความสามารถในการทำปฏิกิริยาไว้ที่อุณหภูมิระหว่างการแปรรูป โครงสร้างผลิตภัณฑ์เติมเต็มของฟอสฟีน-ควินอน สร้างสมบัติเชิงอิเล็กทรอนิกส์เฉพาะตัวที่ช่วยอำนวยความสะดวกในการเริ่มต้นและการขยายตัวของปฏิกิริยาราดิคัลอย่างควบคุมได้ ลักษณะโครงสร้างเหล่านี้ทำให้สารประกอบสามารถคงตัวอยู่ได้ในช่วงเก็บรักษา และแสดงความกระตือรือร้นสูงภายใต้เงื่อนไขการแปรรูปเฉพาะ

การกระตุ้นตามอุณหภูมิถือเป็นหนึ่งในคุณสมบัติที่มีค่าที่สุดของตัวเร่งการแข็งตัวขั้นสูงนี้ ต่างจากตัวเร่งปฏิกิริยาแบบทั่วไปที่อาจแสดงการกระตุ้นก่อนเวลาหรือมีปฏิกิริยาไม่เพียงพอ TPTPBQ แสดงการตอบสนองต่อความร้อนอย่างแม่นยำ ลักษณะการกระตุ้นที่ควบคุมได้นี้ช่วยให้ผู้ผลิตสามารถคงอายุการใช้งานของสารผสม (pot life) ได้นานที่อุณหภูมิห้อง ขณะเดียวกันก็สามารถทำให้เกิดการแข็งตัวอย่างรวดเร็วเมื่อนำไปใช้ที่อุณหภูมิสูง ช่วงการทำงานที่ได้จึงช่วยเพิ่มความยืดหยุ่นในการดำเนินงาน ส่งผลให้ประสิทธิภาพการผลิตดีขึ้นอย่างมากและลดของเสีย

ลักษณะสมรรถนะการเร่งปฏิกิริยา

ประสิทธิภาพของตัวเร่งปฏิกิริยา TPTPBQ ไม่เพียงแต่ช่วยเร่งปฏิกิริยาอย่างเดียว แต่ยังครอบคลุมไปถึงการเพิ่มประสิทธิภาพกระบวนการโดยรวม สารประกอบนี้มีอิทธิพลต่อหลายด้านของปฏิกิริยาการแข็งตัว รวมถึงอัตราการเริ่มต้น อัตราการขยายตัว และกลไกการยุติ ผลลัพธ์ที่ได้จากการควบคุมพลวัตของปฏิกิริยานี้ ทำให้ผู้พัฒนาสูตรสามารถปรับแต่งโปรไฟล์การแข็งตัวให้สอดคล้องกับข้อกำหนดการใช้งานเฉพาะได้อย่างแม่นยำ ความแม่นยำในการควบคุมปฏิกิริยานี้ส่งผลโดยตรงต่อความสม่ำเสมอของผลิตภัณฑ์ที่ดีขึ้น และลดความแปรปรวนของคุณสมบัติทางกล

ปฏิกิริยาร่วมที่เกิดขึ้นอย่างสอดคล้องกับส่วนประกอบอื่นๆ ในการจัดสูตร จะช่วยเพิ่มประสิทธิภาพให้ดียิ่งขึ้นเมื่อนำตัวเร่งการแข็งตัวขั้นสูงนี้มาใช้ร่วมกัน เมื่อผสมผสานกับตัวเร่งปฏิกิริยาหรือตัวเร่งความเร็วที่เหมาะสม TPTPBQ สามารถทำให้ประสิทธิภาพในการผลิตดีขึ้นอย่างมาก สูตรการจัดสูตรที่ได้รับการปรับสมดุลอย่างระมัดระวังนี้ ช่วยให้ผู้ผลิตสามารถปรับแต่งกระบวนการผลิตให้เหมาะสมกับความต้องการเฉพาะของตน พร้อมทั้งคงไว้ซึ่งคุณสมบัติด้านเสถียรภาพและประสิทธิภาพที่ทำให้สารประกอบนี้มีคุณค่าสูงในงานประยุกต์ใช้งานทางอุตสาหกรรม

การประยุกต์ใช้ในอุตสาหกรรมและการได้รับประโยชน์จากการแปรรูป

ภาคอุตสาหกรรมยานยนต์และขนส่ง

อุตสาหกรรมยานยนต์ได้นำเทคโนโลยีการบ่มขั้นสูงมาใช้เพื่อตอบสนองความต้องการด้านประสิทธิภาพที่สูงขึ้นอย่างต่อเนื่อง และเพื่อให้สอดคล้องกับกำหนดการผลิตที่เข้มงวด ชิ้นส่วนที่ต้องเผชิญกับการเปลี่ยนแปลงอุณหภูมิอย่างรุนแรง ความเครียดทางกล และการสัมผัสกับสิ่งแวดล้อม จำเป็นต้องใช้ระบบการบ่มที่ให้ความน่าเชื่อถือและทนทานอย่างยิ่ง สูตรที่เสริมด้วย TPTPBQ ช่วยให้สามารถดำเนินกระบวนการได้อย่างรวดเร็ว ซึ่งจำเป็นต่อการผลิตยานยนต์ในปริมาณมาก ขณะเดียวกันก็รับประกันประสิทธิภาพในระยะยาวภายใต้สภาวะการใช้งานที่ท้าทาย

กาวโครงสร้างและวัสดุคอมโพสิตถือเป็นการประยุกต์ใช้งานที่สำคัญอย่างยิ่ง โดยความเร็วและเสถียรภาพของการแข็งตัวถือเป็นปัจจัยสำคัญ ยานยนต์ขั้นสูงมีชิ้นส่วนประกอบจำนวนหลายชุดที่ต้องผ่านกระบวนการเชื่อมติดด้วยกาว ซึ่งต้องสามารถแข็งตัวได้อย่างรวดเร็วในระหว่างการผลิต และยังคงให้บริการที่เชื่อถือได้นานหลายทศวรรษ อัตราการแข็งตัวที่ดีขึ้นซึ่งเกิดจาก TPTPBQ ทำให้ผู้ผลิตรถยนต์สามารถลดระยะเวลาไซเคิลและเพิ่มปริมาณการผลิตได้ โดยไม่กระทบต่อความแข็งแรงของข้อต่อที่ติดกาวหรือความสามารถในการต้านทานต่อสิ่งแวดล้อม

อิเล็กทรอนิกส์และวัสดุขั้นสูง

การผลิตส่วนประกอบอิเล็กทรอนิกส์ต้องการความแม่นยำสูงในการประมวลผลวัสดุ โดยเฉพาะในด้านการจัดการความร้อนและความมั่นคงด้านมิติ กระบวนการบ่มต้องทำให้เกิดพอลิเมอไรเซชันอย่างสมบูรณ์ ขณะเดียวกันก็ต้องลดความเครียดจากความร้อนให้น้อยที่สุด และหลีกเลี่ยงการเปลี่ยนแปลงมิติที่อาจส่งผลต่อประสิทธิภาพของส่วนประกอบ TPTPBQ ให้ปฏิกิริยาที่ควบคุมได้ ซึ่งจำเป็นต่อการบรรลุข้อกำหนดที่เข้มงวดเหล่านี้ ช่วยให้ผู้ผลิตสามารถผลิตส่วนประกอบอิเล็กทรอนิกส์ที่มีความน่าเชื่อถือสูงและมีคุณลักษณะการทำงานที่สม่ำเสมอ

วัสดุการเคลือบผนึกและชั้นเคลือบป้องกันได้รับประโยชน์อย่างมากจากความเสถียรของการทำให้แข็งตัวที่ดีขึ้นซึ่งมาจากระบบตัวเร่งปฏิกิริยาขั้นสูง แอปพลิเคชันเหล่านี้ต้องการการแข็งตัวอย่างสม่ำเสมอทั่วทั้งรูปทรงเรขาคณิตที่ซับซ้อน พร้อมทั้งยังคงยึดเกาะได้ดีเยี่ยมกับวัสดุพื้นผิวต่างๆ การควบคุมปฏิกิริยาที่ดีขึ้นซึ่งได้จาก TPTPBQ ทำให้เกิดพอลิเมอไรเซชันอย่างสมบูรณ์ แม้ในรูปแบบที่ท้าทาย ส่งผลให้ชิ้นส่วนและชุดอิเล็กทรอนิกส์ที่ไวต่อการเสียหายได้รับการป้องกันอย่างเหนือชั้น

การเพิ่มประสิทธิภาพการผลิตและการควบคุมคุณภาพ

การจัดการอุณหภูมิและการควบคุมปฏิกิริยา

การจัดการอุณหภูมิอย่างมีประสิทธิภาพถือเป็นปัจจัยสำคัญในการเพิ่มประสิทธิภาพกระบวนการบ่มด้วยระบบเร่งปฏิกิริยาขั้นสูง TPTPBQ ช่วยให้สามารถควบคุมความร้อนที่ปลดปล่อยออกมาจากการปฏิกิริยาได้อย่างแม่นยำ ทำให้ผู้ผลิตสามารถรักษาระดับอุณหภูมิที่เหมาะสมตลอดรอบการบ่ม อีกทั้งยังป้องกันการร้อนเกินท้องถิ่นที่อาจก่อให้เกิดการเสื่อมสภาพของวัสดุหรือการบิดงอของรูปร่าง พร้อมทั้งรับประกันการพอลิเมอไรเซชันอย่างสมบูรณ์ทั่วทั้งชิ้นส่วน

ระบบการตรวจสอบและควบคุมกระบวนการสามารถใช้คุณสมบัติการกระตุ้นที่คาดการณ์ได้ของ TPTPBQ เพื่อใช้โปรไฟล์อุณหภูมิที่ซับซ้อนในการเพิ่มประสิทธิภาพทั้งความเร็วและคุณภาพ การตรวจสอบความก้าวหน้าของปฏิกิริยาแบบเรียลไทม์ ช่วยให้สามารถปรับพารามิเตอร์การผลิตได้ตามความต้องการ เพื่อรักษาระบบให้อยู่ในสภาวะที่เหมาะสมตลอดวงจรการบ่ม ความสามารถขั้นสูงในการควบคุมกระบวนการเช่นนี้ ส่งผลโดยตรงต่อการปรับปรุงคุณภาพผลิตภัณฑ์ และลดต้นทุนการผลิตจากการลดของเสียและการต้องแก้ไขงาน

การประกันคุณภาพและการตรวจสอบประสิทธิภาพ

โปรโตคอลการควบคุมคุณภาพอย่างครอบคลุมมีความจำเป็นต่อการยืนยันประโยชน์ด้านประสิทธิภาพที่ได้จากการใช้เทคโนโลยีการบ่มขั้นสูง ขั้นตอนการทดสอบจะต้องประเมินไม่เพียงแต่ความเร็วของปฏิกิริยาการบ่ม แต่ยังรวมถึงสมบัติทางกล ความเสถียรทางความร้อน และความต้านทานต่อสิ่งแวดล้อมของวัสดุที่ผ่านกระบวนการบ่มแล้ว สูตรที่เสริมด้วย TPTPBQ แสดงผลการดำเนินงานที่เหนือกว่าอย่างต่อเนื่องในพารามิเตอร์สำคัญเหล่านี้ ซึ่งช่วยให้ผู้ผลิตมั่นใจในความก้าวหน้าของกระบวนการผลิต

การทดสอบความเสถียรในระยะยาวเปิดเผยถึงข้อได้เปรียบด้านความทนทานอันยอดเยี่ยมที่เกิดจากกระบวนการบ่มที่ได้รับการปรับให้เหมาะสม วัสดุที่ผ่านการบ่มด้วยระบบเร่งปฏิกิริยาขั้นสูงแสดงความสามารถในการต้านทานต่อการเปลี่ยนแปลงอุณหภูมิ ความชื้น และการโจมตีจากสารเคมีได้ดีกว่าวัสดุที่บ่มแบบทั่วไป ความก้าวหน้าด้านประสิทธิภาพเหล่านี้ส่งผลให้อายุการใช้งานของชิ้นส่วนและชุดประกอบที่ใช้วัสดุเสริมด้วย TPTPBQ เพิ่มขึ้น และลดความต้องการในการบำรุงรักษา

ผลกระทบทางเศรษฐกิจและประสิทธิภาพในการผลิต

การปรับปรุงต้นทุนการผลิต

ประโยชน์ทางเศรษฐกิจจากการนำเทคโนโลยีการบ่มขั้นสูงมาใช้นั้นล้ำลึกไปไกลกว่าการลดระยะเวลาไซเคิลเพียงอย่างเดียว กระบวนการบ่มที่เร็วขึ้นช่วยเพิ่มอัตราการใช้งานอุปกรณ์ ลดการใช้พลังงานต่อหน่วยที่ผลิต และลดต้นทุนแรงงานผ่านความเข้ากันได้ที่ดีขึ้นกับระบบอัตโนมัติ TPTPBQ มีส่วนช่วยในด้านประโยชน์ทางเศรษฐกิจเหล่านี้ โดยช่วยให้ผู้ผลิตสามารถปรับปรุงประสิทธิภาพการผลิตได้อย่างมาก โดยไม่จำเป็นต้องลงทุนเพิ่มในอุปกรณ์ใหม่

การลดการเกิดของเสียถือเป็นอีกหนึ่งประโยชน์ทางเศรษฐกิจที่สำคัญของกระบวนการบ่มที่ได้รับการปรับปรุง การควบคุมกระบวนการที่ดีขึ้นและความสม่ำเสมอมากขึ้นที่ได้จาก TPTPBQ ช่วยลดปัญหาชิ้นส่วนที่บกพร่อง และลดความจำเป็นในการแก้ไขหรือทิ้งชิ้นงาน คุณภาพที่ดีขึ้นเหล่านี้ส่งผลโดยตรงต่อการลดต้นทุนวัสดุ และเพิ่มประสิทธิภาพโดยรวมของอุปกรณ์ ซึ่งช่วยส่งเสริมให้เกิดการปรับปรุงอย่างมีนัยสำคัญในด้านกำไรจากการผลิต

ความแข่งขันในตลาดและการนวัตกรรม

บริษัทที่นำเทคโนโลยีการบ่มขั้นสูงไปใช้สำเร็จ จะได้รับข้อได้เปรียบในการแข่งขันอย่างมากจากการปรับปรุงคุณภาพผลิตภัณฑ์ ลดต้นทุนการผลิต และเพิ่มความยืดหยุ่นในการผลิต ความสามารถในการเสนอระยะเวลาการผลิตที่สั้นลง พร้อมทั้งรักษาระดับประสิทธิภาพของผลิตภัณฑ์ที่เหนือกว่า ช่วยสร้างความแตกต่างที่มีคุณค่าในตลาดที่มีการแข่งขันสูง TPTPBQ ช่วยให้ผู้ผลิตสามารถบรรลุข้อได้เปรียบในการแข่งขันเหล่านี้ พร้อมทั้งรักษาระดับความน่าเชื่อถือและความสม่ำเสมอที่ลูกค้าต้องการ

โอกาสในการสร้างนวัตกรรมเกิดขึ้นจากขีดความสามารถในการแปรรูปที่ดีขึ้นซึ่งระบบการบ่มขั้นสูงมอบให้ ผู้ผลิตสามารถสำรวจออกแบบผลิตภัณฑ์ วัสดุผสม และการใช้งานรูปแบบใหม่ที่เดิมอาจไม่สามารถทำได้จริง เนื่องจากข้อจำกัดด้านการแปรรูป ช่วงการแปรรูปกว้างขึ้นและคุณลักษณะการควบคุมที่ดีขึ้นของสูตรที่เสริมด้วย TPTPBQ ทำให้สามารถพัฒนานวัตกรรมใหม่ๆ ที่ตอบสนองความต้องการของตลาดและลูกค้าที่เปลี่ยนแปลงไป

การพิจารณาด้านสิ่งแวดล้อมและความยั่งยืน

ประสิทธิภาพพลังงานและการปล่อยคาร์บอน

ความยั่งยืนต่อสิ่งแวดล้อมได้กลายเป็นปัจจัยที่สำคัญเพิ่มขึ้นในการดำเนินกระบวนการผลิตในอุตสาหกรรม เทคโนโลยีการอบช่วยเสริมสร้างเป้าหมายด้านความยั่งยืนผ่านการลดการใช้พลังงาน การลดปริมาณของเสีย และการเพิ่มประสิทธิภาพการใช้วัสดุ TPTPBQ ช่วยให้ผู้ผลิตสามารถลดความต้องการพลังงานในการประมวลผลอย่างมีนัยสำคัญ พร้อมทั้งรักษาระดับหรือปรับปรุงคุณสมบัติของผลิตภัณฑ์

อุณหภูมิการอบที่ต่ำลงและระยะเวลาการประมวลผลที่สั้นลง ส่งผลโดยตรงต่อการลดการปล่อยก๊าซคาร์บอนและผลกระทบต่อสิ่งแวดล้อม ประสิทธิภาพที่ดีขึ้นจากการใช้ระบบเร่งปฏิกิริยาขั้นสูง ทำให้ผู้ผลิตสามารถปฏิบัติตามข้อกำหนดด้านสิ่งแวดล้อมและความมุ่งมั่นด้านความยั่งยืน ขณะเดียวกันก็รักษาระดับต้นทุนการผลิตที่สามารถแข่งขันได้ ประโยชน์ด้านสิ่งแวดล้อมเหล่านี้มีค่ามากขึ้นเรื่อย ๆ เมื่อกฎระเบียบมีความเข้มงวดมากขึ้น และความต้องการของลูกค้าเปลี่ยนไปสู่ผลิตภัณฑ์ที่ยั่งยืน

การลดขยะและการอนุรักษ์ทรัพยากร

การควบคุมกระบวนการและความสม่ำเสมอยิ่งขึ้นที่ได้จากการใช้เทคโนโลยีการบ่มขั้นสูง ช่วยลดการเกิดของเสียและการใช้วัสดุลงอย่างมีนัยสำคัญ ความน่าเชื่อถือที่เพิ่มขึ้นของกระบวนการที่เสริมด้วย TPTPBQ ยังช่วยลดผลิตภัณฑ์ชำรุดที่ต้องทิ้งหรือรีไซเคิล ซึ่งการลดของเสียนี้ส่งผลดีทั้งต่อความยั่งยืนทางสิ่งแวดล้อมและประสิทธิภาพทางเศรษฐกิจ โดยเพิ่มมูลค่าที่ได้จากวัตถุดิบให้มากที่สุด

ประโยชน์ด้านการอนุรักษ์ทรัพยากรไม่ได้จำกัดอยู่แค่การประหยัดวัสดุโดยตรงเท่านั้น แต่ยังรวมถึงการลดการใช้พลังงาน น้ำ และทรัพยากรในการดำเนินการอื่นๆ การปรับปรุงประสิทธิภาพที่ได้จากระบบการบ่มขั้นสูง ช่วยลดผลกระทบต่อสิ่งแวดล้อมโดยรวมของการดำเนินงานการผลิต ในขณะเดียวกันก็ยังช่วยเพิ่มประสิทธิภาพทางเศรษฐกิจ ข้อได้เปรียบด้านความยั่งยืนเหล่านี้จึงมีความสำคัญเพิ่มขึ้นเรื่อยๆ เนื่องจากผู้ผลิตกำลังเผชิญกับแรงกดดันที่เพิ่มขึ้นในการลดผลกระทบต่อสิ่งแวดล้อม พร้อมทั้งรักษาความสามารถในการแข่งขันของการดำเนินงาน

คำถามที่พบบ่อย

อะไรทำให้ TPTPBQ มีประสิทธิภาพมากกว่าตัวเร่งการอบแข็งแบบดั้งเดิม

TPTPBQ มีความเสถียรทางความร้อนที่เหนือกว่าและคุณสมบัติในการกระตุ้นอย่างควบคุมเมื่อเทียบกับตัวเร่งการอบแข็งแบบทั่วไป โครงสร้างโมเลกุลที่เป็นเอกลักษณ์ของมันช่วยให้มีปฏิกิริยาขึ้นอยู่กับอุณหภูมิอย่างแม่นยำ ทำให้สามารถอบแข็งได้เร็วขึ้นที่อุณหภูมิสูง ในขณะที่ยังคงรักษาความเสถียรในการจัดเก็บได้ดีภายใต้สภาวะปกติ การรวมกันของคุณสมบัติเหล่านี้ช่วยให้ผู้ผลิตสามารถลดระยะเวลาไซเคิลได้โดยไม่กระทบต่อคุณภาพผลิตภัณฑ์หรือความน่าเชื่อถือในการประมวลผล

TPTPBQ ช่วยปรับปรุงคุณสมบัติทางกลของวัสดุที่ผ่านการอบแข็งแล้วอย่างไร

ปฏิกิริยาเคมีที่มีการควบคุมอัตราด้วย TPTPBQ ส่งผลให้เกิดการเชื่อมโยงข้ามอย่างสม่ำเสมอมากขึ้น และช่วยปรับปรุงโครงข่ายวัสดุหลังการบ่ม ซึ่งการเชื่อมโยงข้ามที่ดียิ่งขึ้นนี้นำไปสู่คุณสมบัติทางกลที่เหนือกว่า ได้แก่ ความแข็งแรงดึงเพิ่มขึ้น ความต้านทานต่อแรงกระแทกดีขึ้น และความคงตัวของขนาดที่ดีขึ้น นอกจากนี้ การบ่มที่สม่ำเสมอจากการใช้ตัวเร่งปฏิกิริยารุ่นใหม่นี้ยังช่วยลดความเครียดภายในที่อาจส่งผลต่อประสิทธิภาพในระยะยาว

เงื่อนไขการแปรรูปใดที่ช่วยเพิ่มประสิทธิภาพของ TPTPBQ ได้ดีที่สุด

โดยทั่วไป เพื่อให้ได้ประสิทธิภาพสูงสุดกับ TPTPBQ จำเป็นต้องควบคุมอุณหภูมิ เวลา และสมดุลของสูตรผสมอย่างระมัดระวัง อุณหภูมิในการแปรรูปควรเลือกให้สามารถกระตุ้นปฏิกิริยาได้อย่างรวดเร็ว โดยหลีกเลี่ยงปฏิกิริยาเอกโซเทอร์มิกที่มากเกินไป การออกแบบสูตรผสมที่เหมาะสม รวมถึงการใช้ตัวเร่งปฏิกิริยาร่วมและสารยับยั้งที่เหมาะสม จะช่วยให้ควบคุมปฏิกิริยาได้อย่างมีประสิทธิภาพ และพัฒนาคุณสมบัติสุดท้ายของผลิตภัณฑ์ได้อย่างเต็มที่ ระบบตรวจสอบและควบคุมกระบวนการจะช่วยรักษาสภาวะที่สม่ำเสมอตลอดรอบการบ่ม

มีข้อพิจารณาด้านความปลอดภัยอะไรบ้างเมื่อทำงานกับ TPTPBQ

เช่นเดียวกับสารเคมีอุตสาหกรรมทั่วไป TPTPBQ จำเป็นต้องมีขั้นตอนการปฏิบัติและการป้องกันด้านความปลอดภัยที่เหมาะสม ควรปฏิบัติตามหลักสุขอนามัยอุตสาหกรรมมาตรฐาน ได้แก่ การระบายอากาศที่เหมาะสม อุปกรณ์ป้องกันส่วนบุคคล และขั้นตอนการจัดเก็บอย่างปลอดภัย แผ่นข้อมูลความปลอดภัยของวัสดุจะให้ข้อมูลโดยละเอียดเกี่ยวกับข้อกำหนดในการปฏิบัติงาน ขั้นตอนฉุกเฉิน และแนวทางการกำจัด การฝึกอบรมเจ้าหน้าที่เกี่ยวกับเทคนิคการปฏิบัติที่ถูกต้องจะช่วยให้มั่นใจได้ถึงการใช้งานตัวทำให้แข็งขั้นสูงนี้อย่างปลอดภัยและมีประสิทธิภาพ