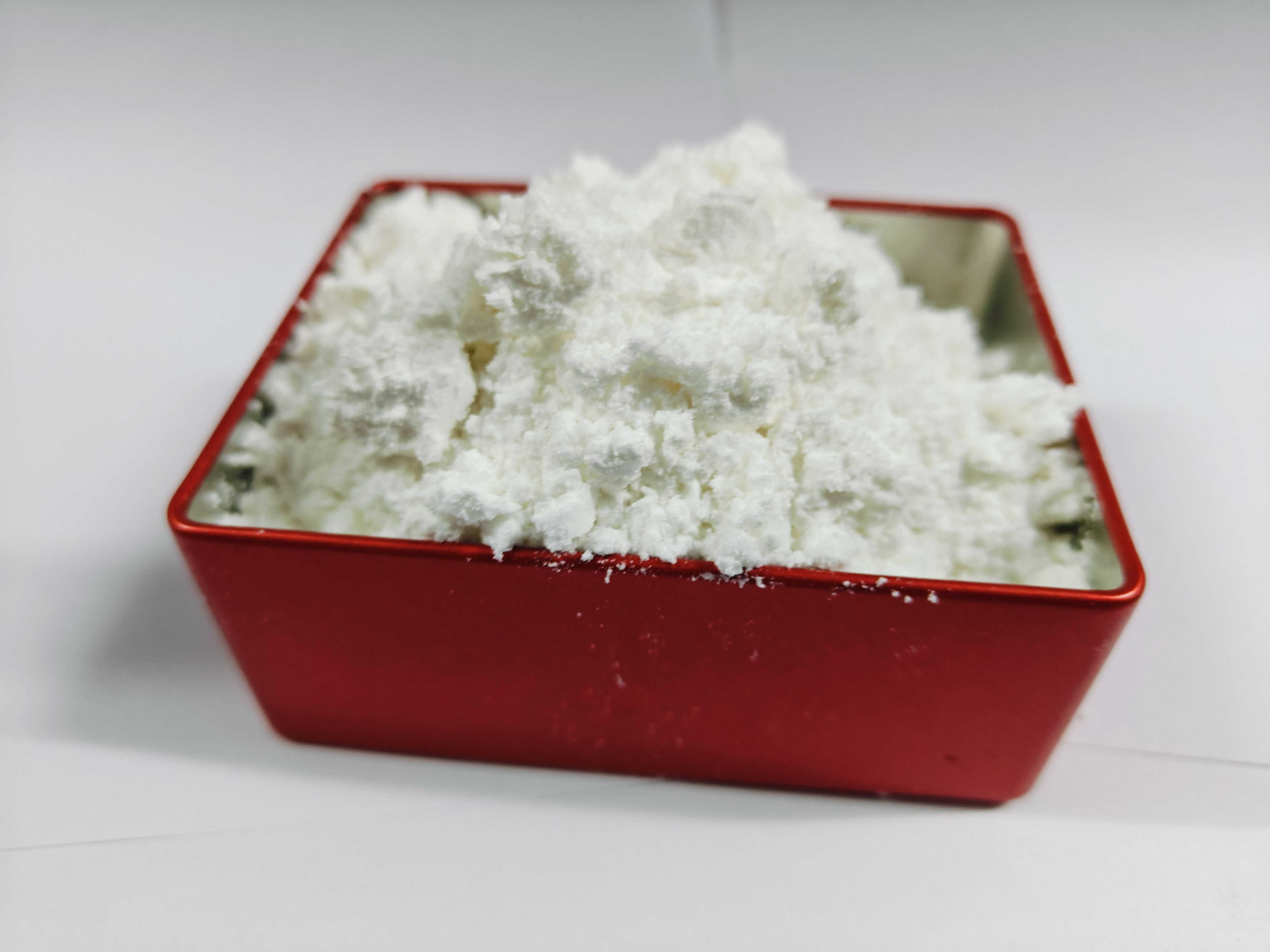

catalasaithe inaiciálta thearmail den chéad chaighdeán

Catalasaithe dea-chothromacha théarmhaigh thugann briseadh scéalta i dtéicneolaíocht próiseálaíochta na héigeandaise. Tá na comhdhála catalásacha sochaideacha seo faoi mhéid amach ag teampall téarmach ach a bhfuil siad ag obair go hiomlán nuair a luaitear dóibh trí shonraí théarmacha speisialta. Tá fo-thriail moladaí leagtha acu a ligíonn an-téarmaíocht rithiúil a chur i gcinn, ag déanamh acu níos éifeachtúla ná mar sin ar fud na ndaltaí saor. Tá a gcuid cumaisc speisialta acu chun stóras dífhostaithe a chur i gcinn faoi réigiúnacha coitianta agus chun taithí catalásacha láidre a chur ar fáil nuair a théitear orthu go dtéirmeanna théarmhaigh riachtanacha. Is féidir leo dul chun cinn go soiléir i bpriocéiseanna polaiméarachta, go háirithe i gclárúcháin, i luchtú adhmaid agus i gcruthú mhatéadálacha choimpiosta. Tá an téicneolaíocht tar éis cur síos ar struchtúracha cheimiceacha tábhachtacha atá ag gabháil athrú idirghníomhach ag teorainn téarmhaigh, ag léamh a gcuid suíocháin gníomhach agus ag tosú na réacsáin is cumasa. An méid seo a fhágann an-mhéid airgeadach do réacsáin roimh ré, ag nochtadh an-chloch agus ag cinntiú gach cáil phróducte. Is féidir leo a bheith ag feabhsú don téarma éagsúil a chuirtear i bhfeidhm, as ucht 60°C go 180°C, ag tabhairt seans éagsúla tríd fhrithphróiseálaíocht éagsúla. Tá an-cloch acu agus an-díbirt agus is iad sin an-bhunachar iontach san eigeandais chóimheachta, go háirithe sna himpleachtaí a thagann isteach ina réacsáin téamaíochta agus ina phróiseálaíocht chun críochnú.