point de fusion du cdi

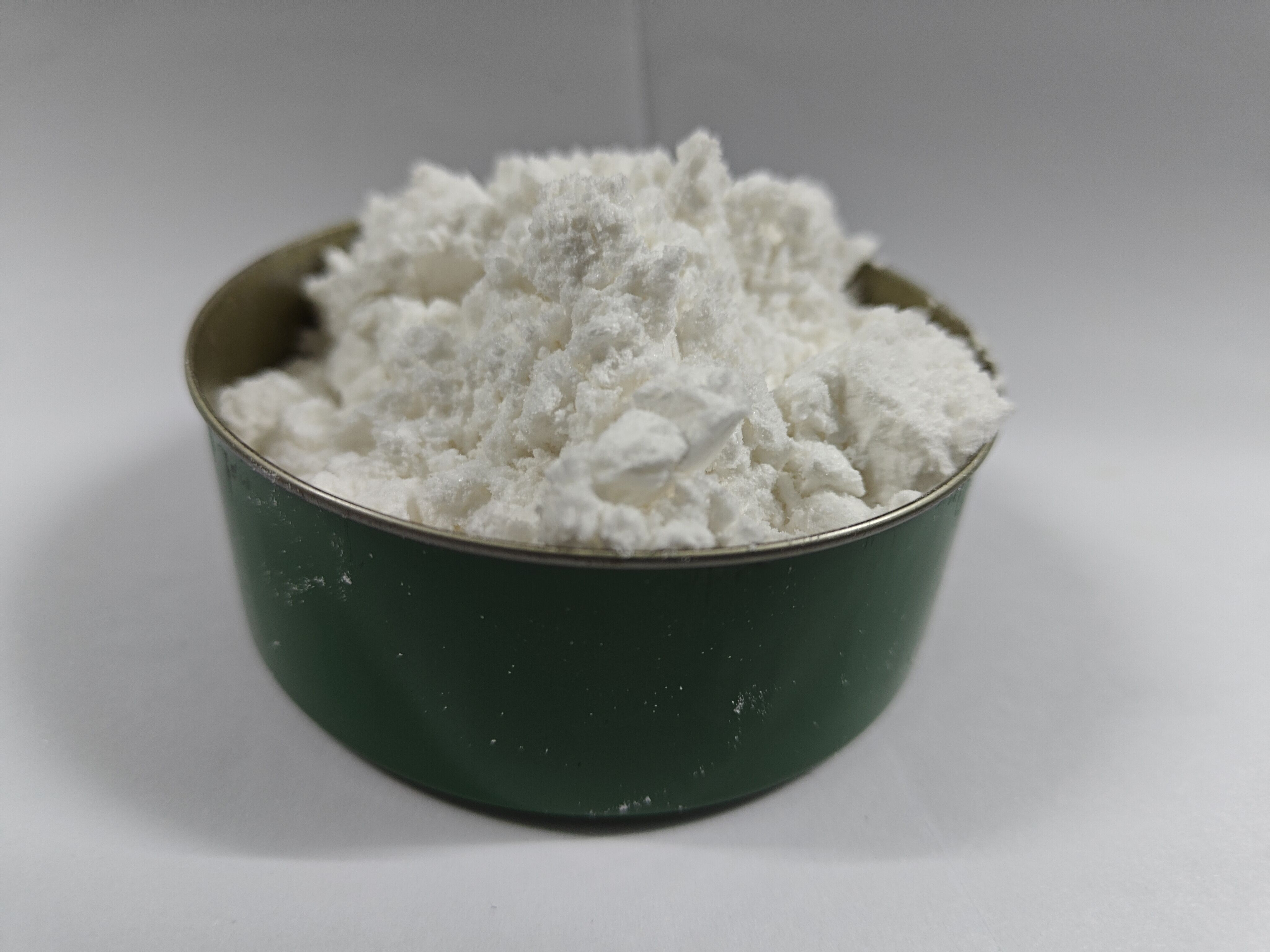

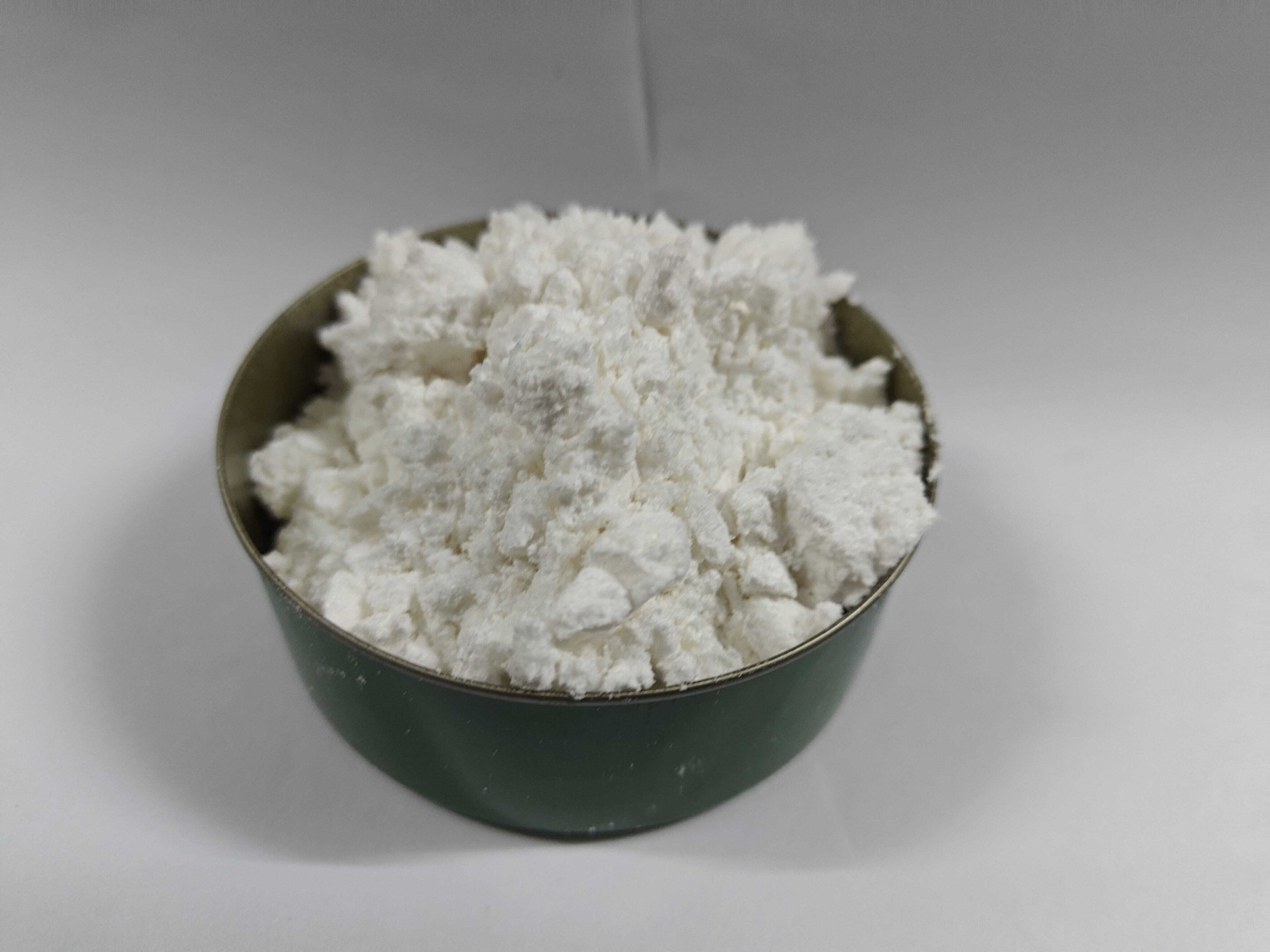

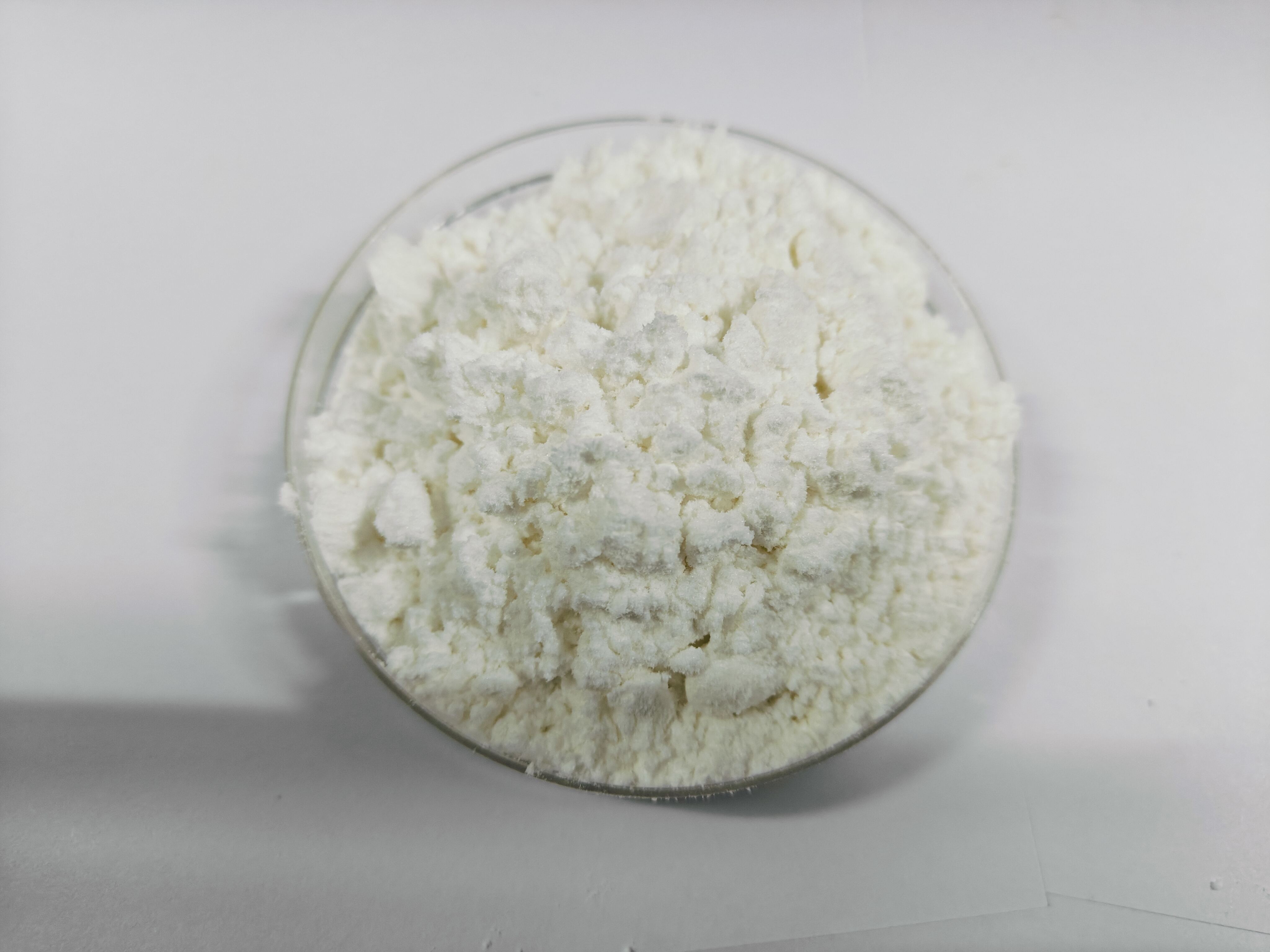

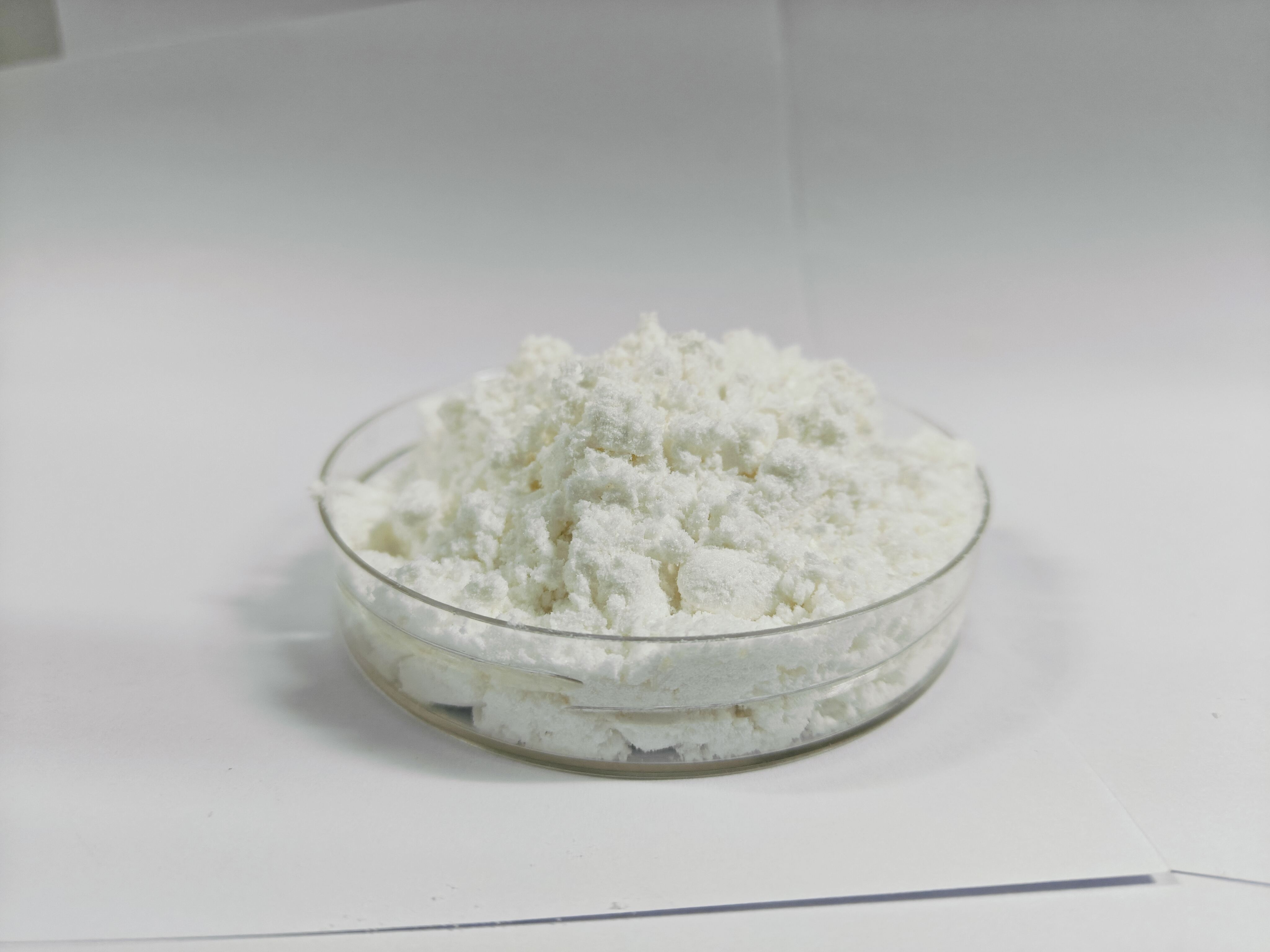

Le système de point de fusion CDI représente une avancée significative dans la chimie analytique et la science des matériaux. Cet instrument sophistiqué détermine précisément le point de fusion de diverses substances, un paramètre crucial dans l'analyse chimique et le contrôle qualité. Le système utilise une technologie de numérisation d'image à la pointe de l'innovation combinée à un contrôle de température automatisé pour fournir des résultats précis et reproductibles. Fonctionnant dans une plage de température de 25°C à 400°C, l'appareil de point de fusion CDI utilise des caméras haute résolution pour capturer et analyser en temps réel le processus de transition de phase. Le logiciel intelligent du système détecte automatiquement les changements physiques dans l'échantillon, éliminant ainsi les erreurs humaines et les interprétations subjectives. Son mécanisme de chauffage précis assure une distribution uniforme de la température, tandis que l'affichage numérique offre des lectures claires et des capacités de journalisation des données. L'instrument peut traiter plusieurs échantillons simultanément, augmentant ainsi l'efficacité et le débit du laboratoire. Cette technologie trouve des applications étendues dans la recherche pharmaceutique, les laboratoires académiques, les départements de contrôle qualité et les installations de fabrication chimique, où une détermination précise du point de fusion est essentielle pour l'identification des substances et l'évaluation de leur pureté.