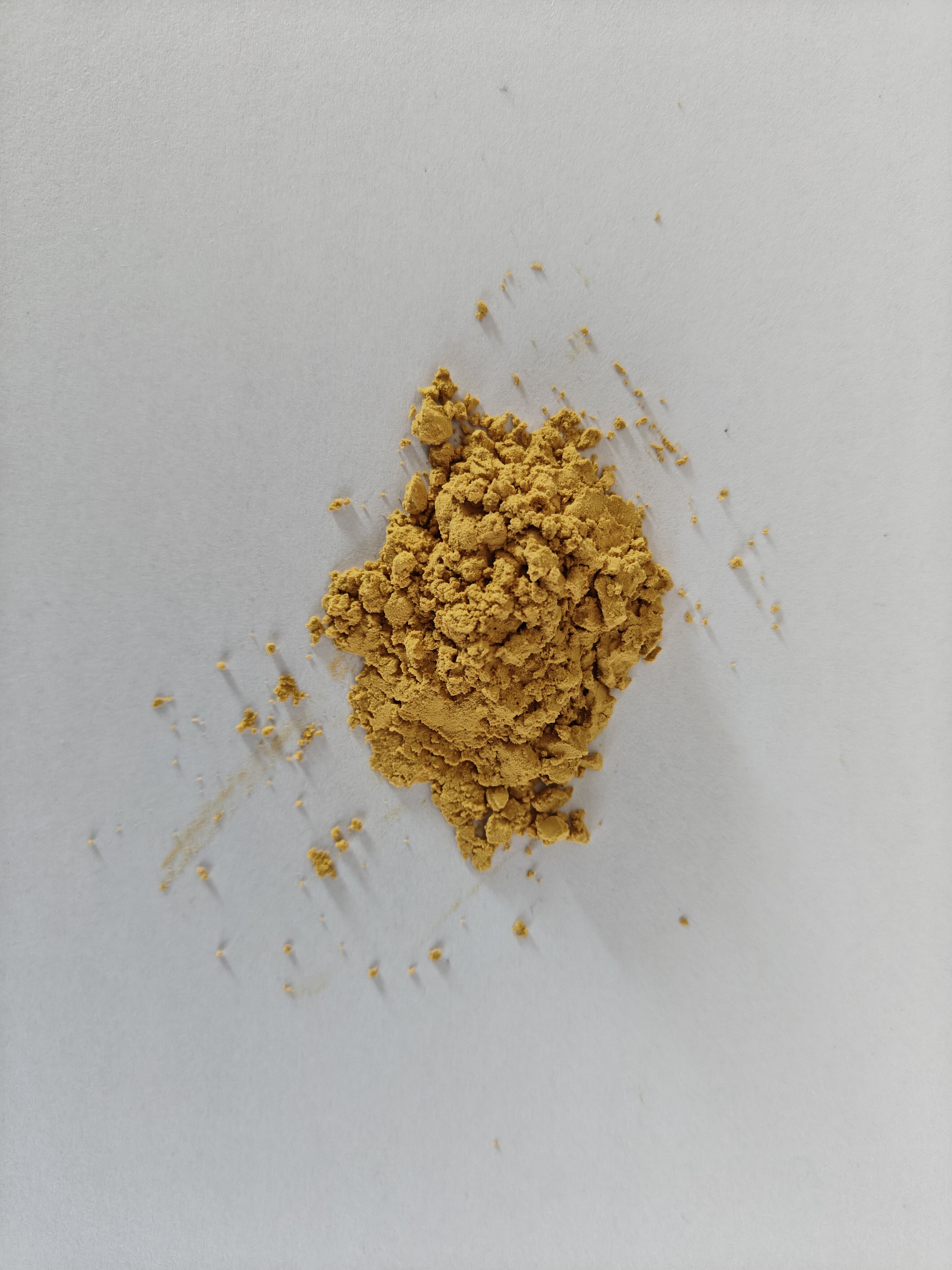

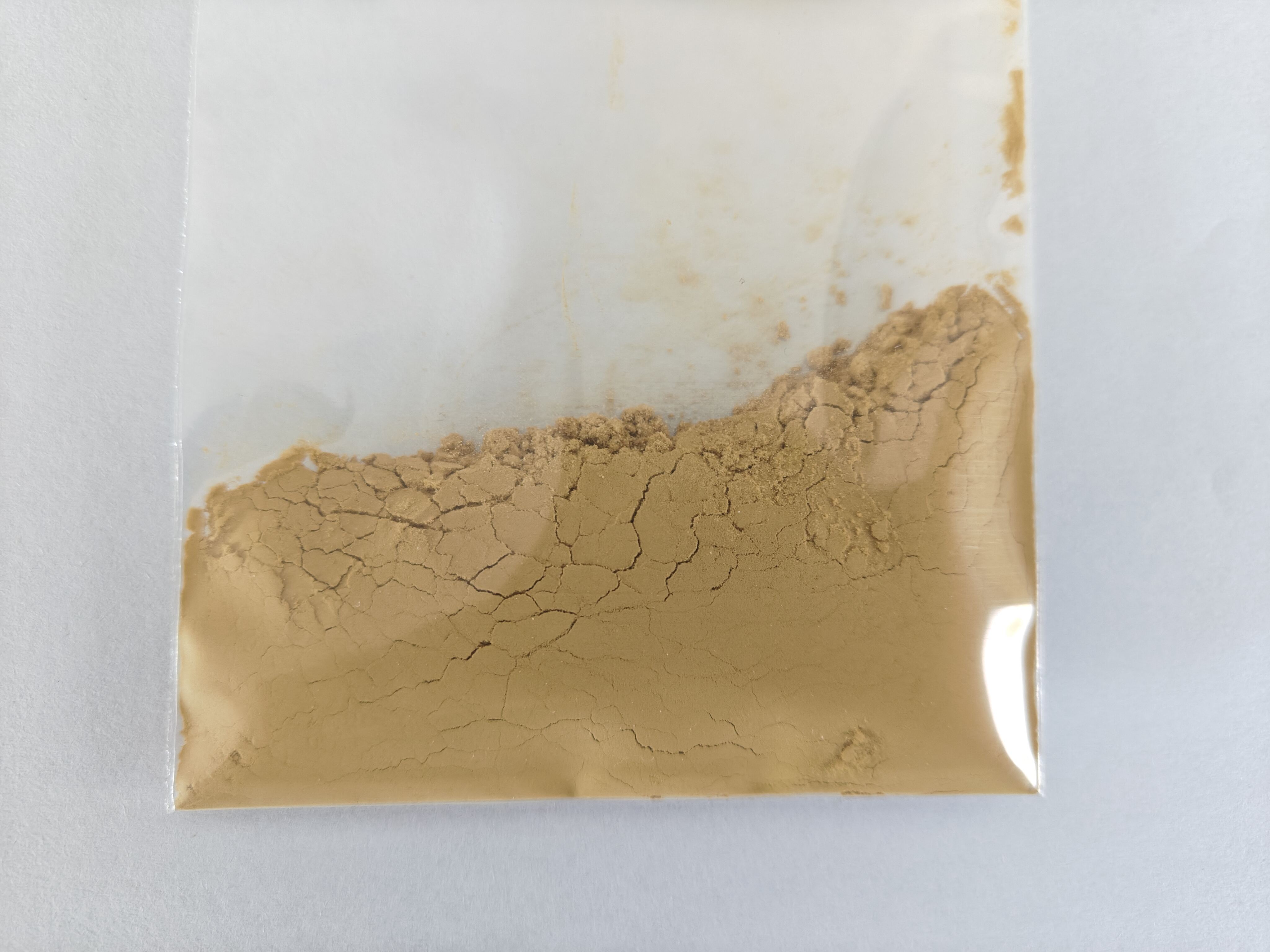

агент за твърдеене на смоли

Съставът за изтвърдяване на смола е ключов компонент в полимерната индустрия, като служи като катализатор, който инициира и контролира процеса на втвърдяване на различни смолни системи. Това есенциално химическо съединение превръща течните смоли в твърди, трайни материали чрез кръстосани връзки. Работещи както при околна, така и при повишена температура, агентите за изтвърждаване на смола определят критични свойства като продължителност на живота на горския съд, скорост на изтвърждаване и крайните механични характеристики на изтвърждавания материал. Тези агенти са налични в множество форми, включително амини, ангидриди и феноли, всеки от които е предназначен за специфични приложения и изисквания за производителност. В промишлените приложения те играят жизненоважна роля в производството на композитни материали, лепила, покрития и електронни компоненти. Изборът на подходящо оцветяващо средство оказва значително влияние върху топлоустойчивостта, химическата устойчивост и цялостната трайност на крайния продукт. Съвременните агенти за изтвърдяване на смола са проектирани да осигуряват точен контрол върху условията на изтвърдяване, като осигуряват последователно качество в производствените процеси. Те са от съществено значение в индустрии, вариращи от аерокосмическата и автомобилната промишленост до строителството и електрониката, където допринасят за създаването на високопроизводителни материали със специфични механични и химически свойства.