the cdi amide bonds

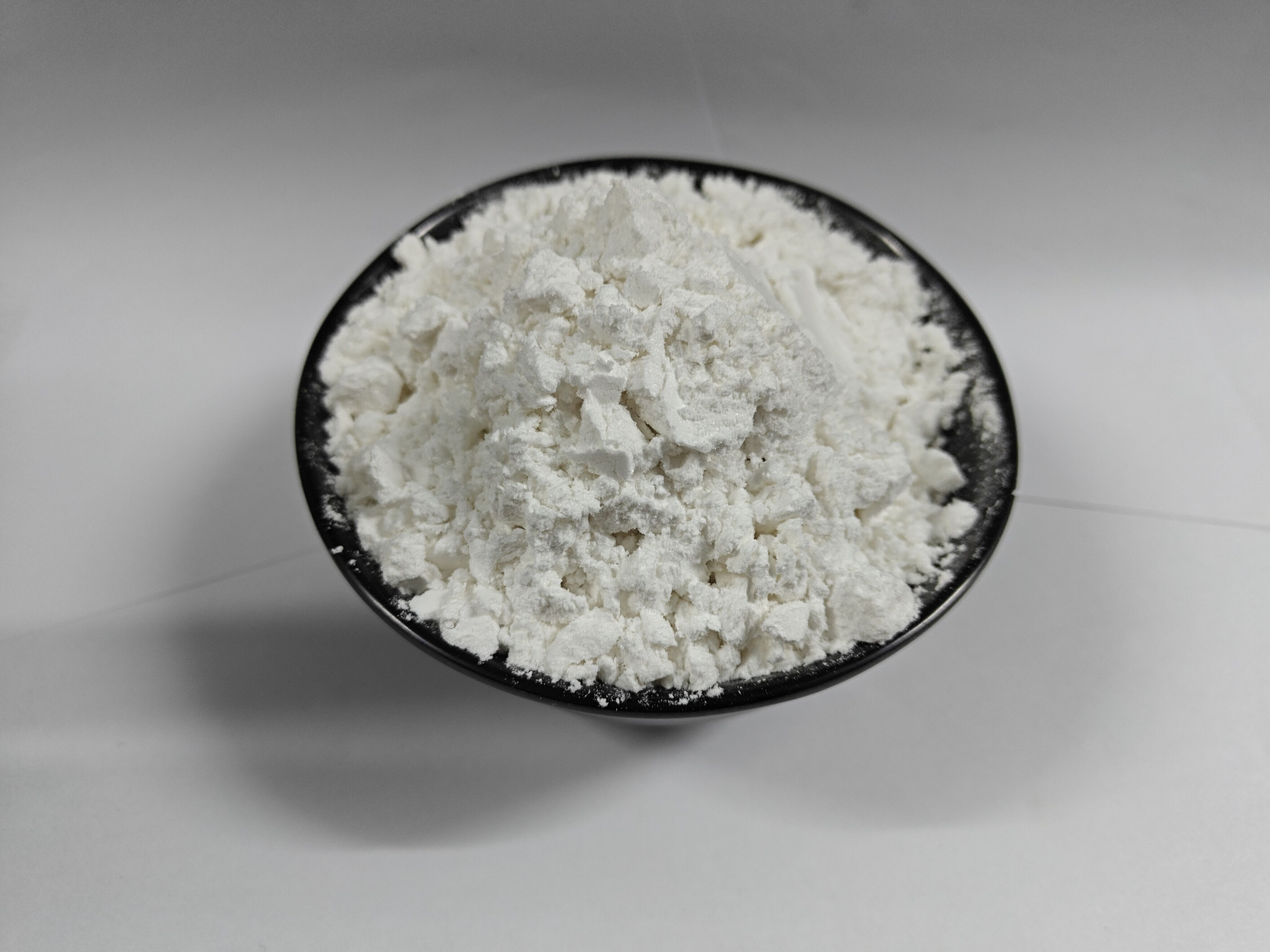

CDI (Carbonyldiimidazole) amide bonds represent a crucial advancement in synthetic chemistry and pharmaceutical development. These bonds are formed through a reaction between carboxylic acids and amines, using CDI as an efficient coupling reagent. The process creates stable amide linkages essential for peptide synthesis and drug development. The formation of CDI amide bonds occurs under mild conditions, making it particularly valuable for sensitive molecular structures. This method offers superior selectivity and high yields compared to traditional coupling methods, while producing minimal side products. The technology enables precise control over bond formation, crucial for manufacturing complex pharmaceutical compounds, peptides, and other bioactive molecules. In industrial applications, CDI amide bonds are instrumental in producing various pharmaceuticals, agrochemicals, and specialty chemicals. The method's versatility allows for both small-scale laboratory synthesis and large-scale industrial production. Additionally, the reaction's compatibility with various functional groups and its environmentally friendly nature make it a preferred choice in green chemistry initiatives. The water-soluble by-products and the absence of toxic waste streams further enhance its appeal in sustainable chemical processes.