emc curing accelerators manufacturer

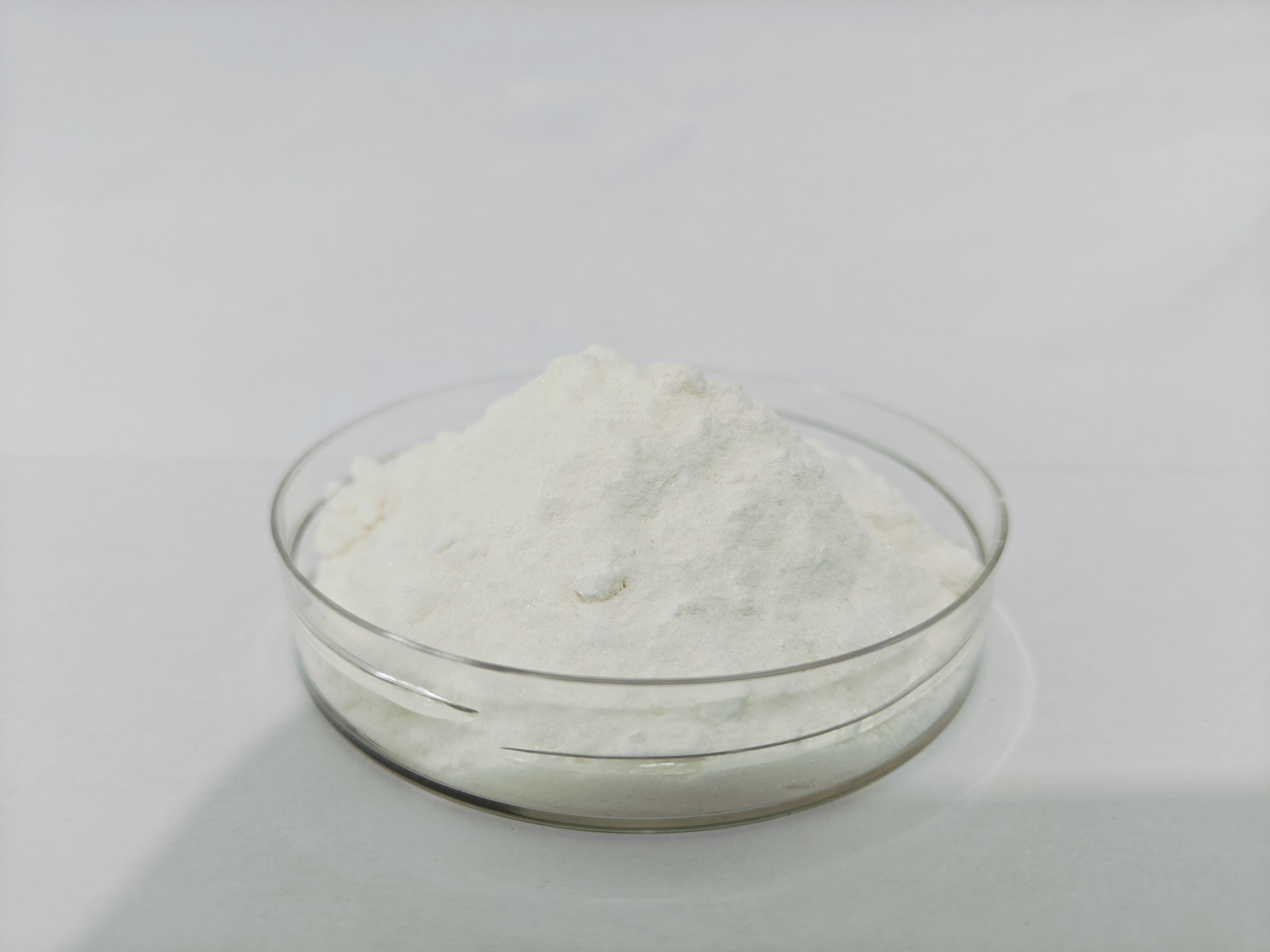

An EMC curing accelerators manufacturer stands as a crucial player in the electronic materials industry, specializing in the production of high-quality curing accelerators for epoxy molding compounds. These manufacturers employ state-of-the-art production facilities and advanced quality control systems to ensure consistent product performance. Their manufacturing processes incorporate precise temperature control, automated mixing systems, and sophisticated particle size management to create accelerators that meet strict industry standards. The facilities typically feature clean room environments, advanced testing laboratories, and robust research and development capabilities. These manufacturers produce various types of curing accelerators, including imidazole-based, amine-based, and phenol-based accelerators, each designed for specific applications in semiconductor packaging. Their products are essential in electronic packaging processes, particularly in integrated circuit encapsulation, where they help achieve optimal curing speeds and enhance the overall performance of electronic components. The manufacturer's commitment to quality is demonstrated through comprehensive testing procedures, including thermal analysis, rheological testing, and reliability assessments. They also provide technical support services, helping customers optimize their manufacturing processes and solve complex challenges in electronic packaging applications.