nncarbonyldiimidazol

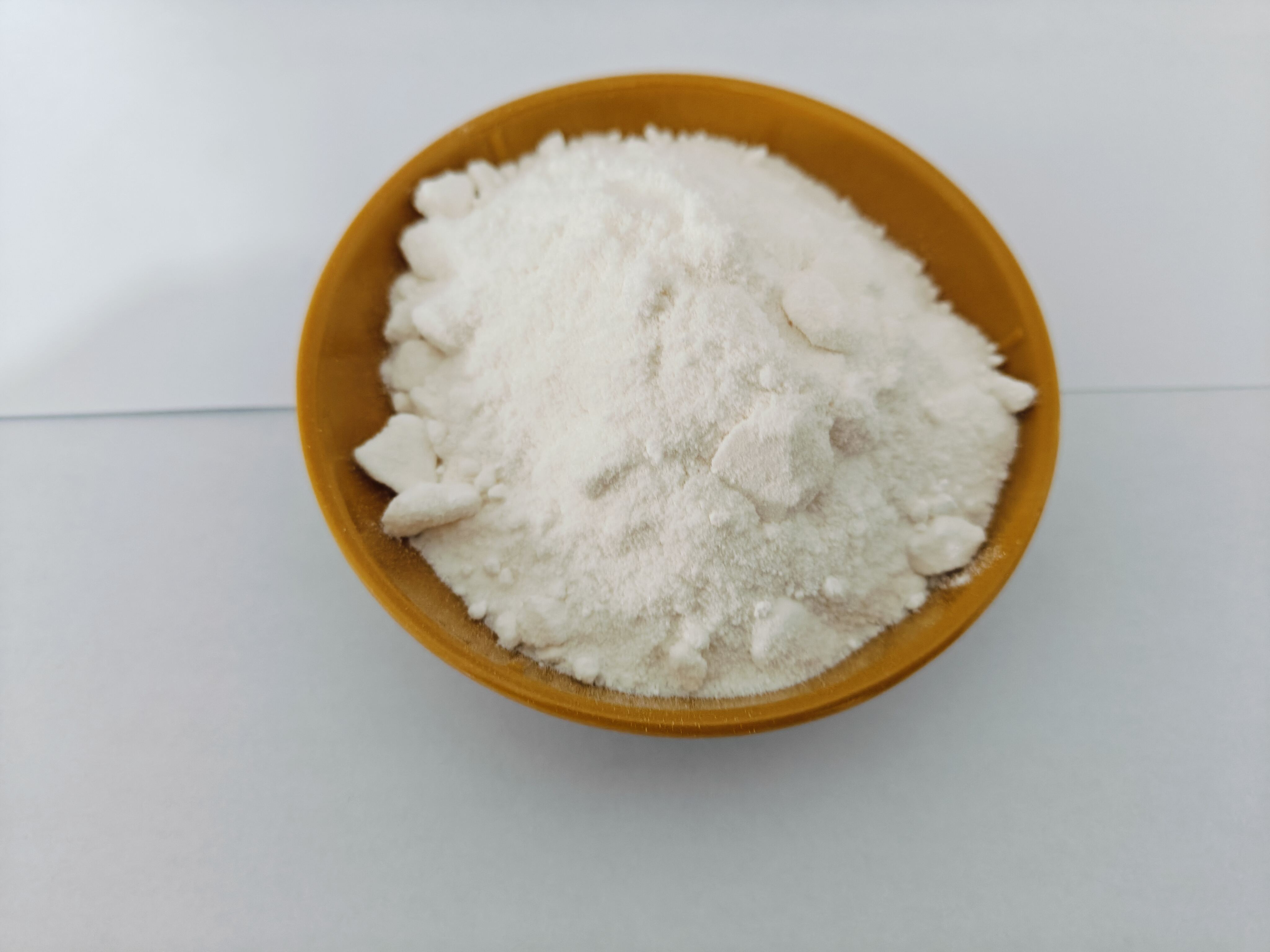

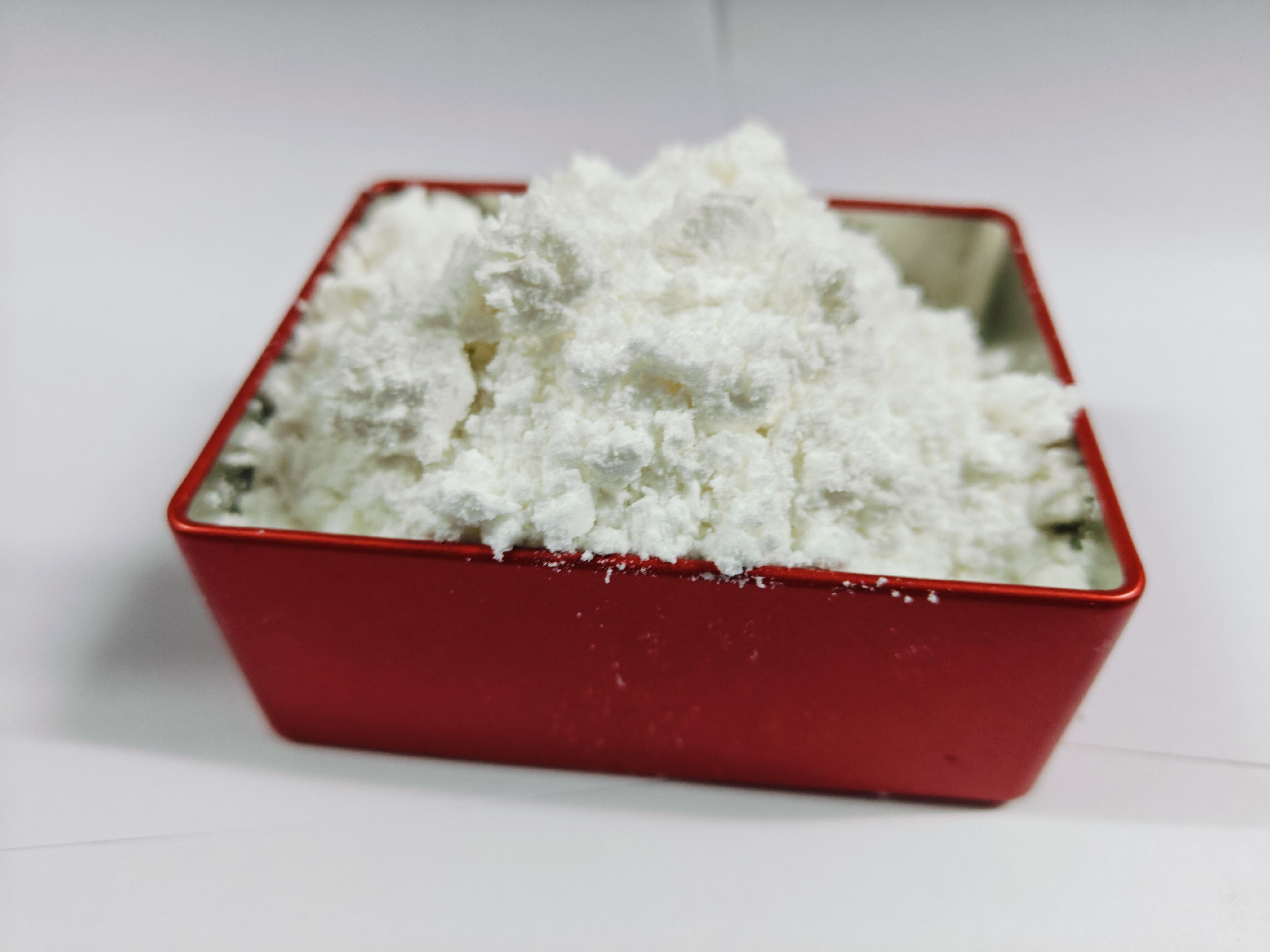

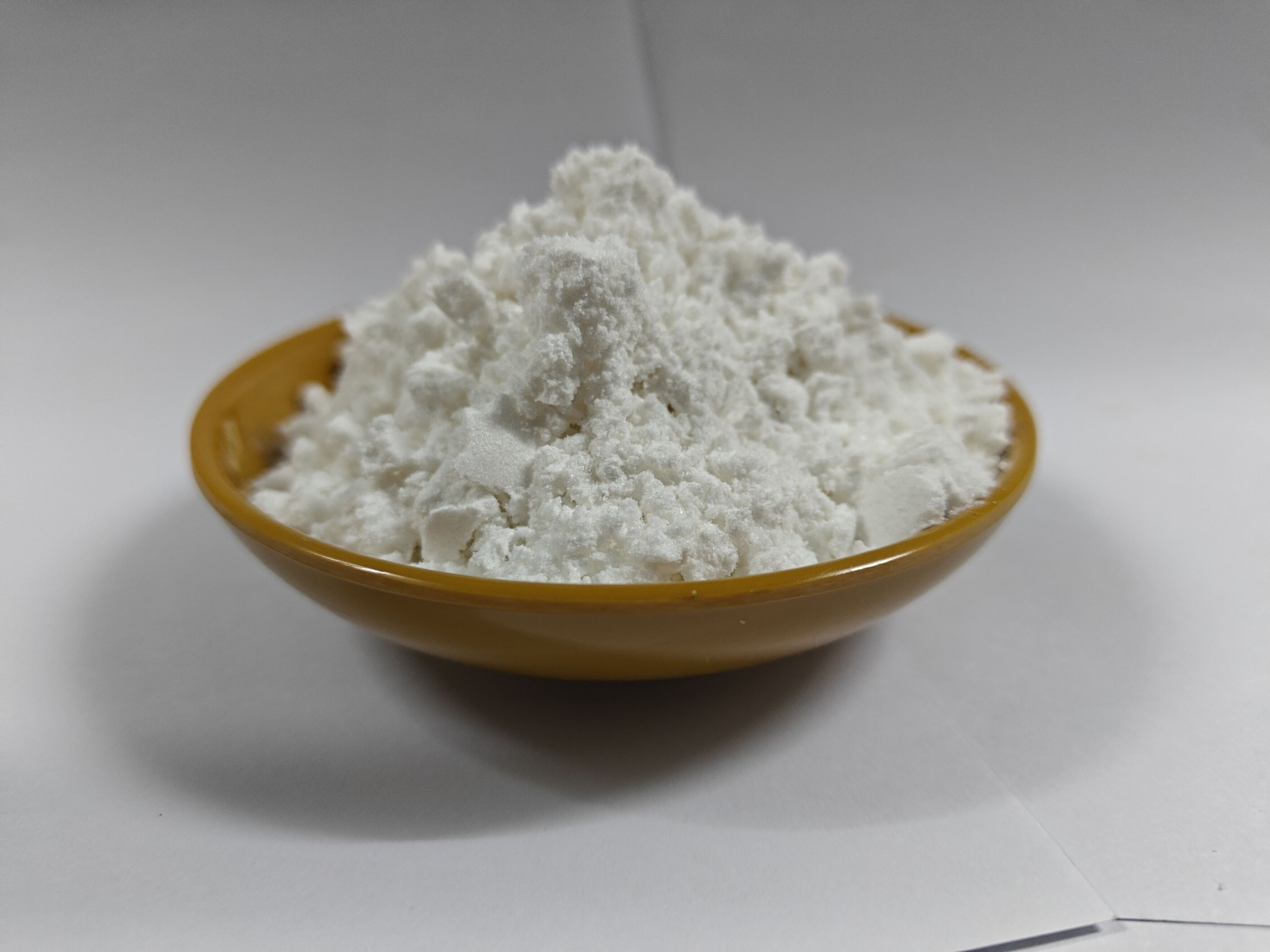

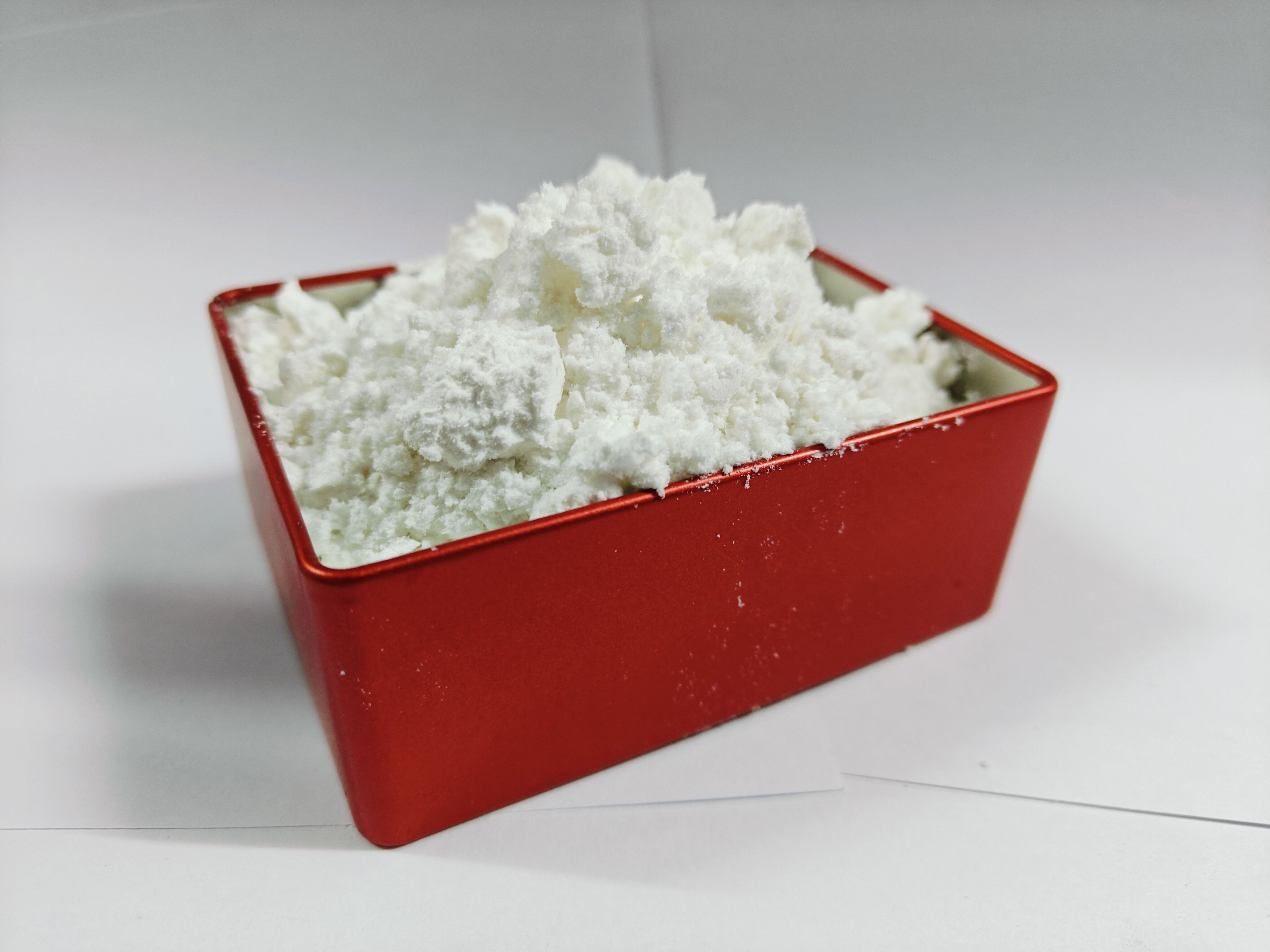

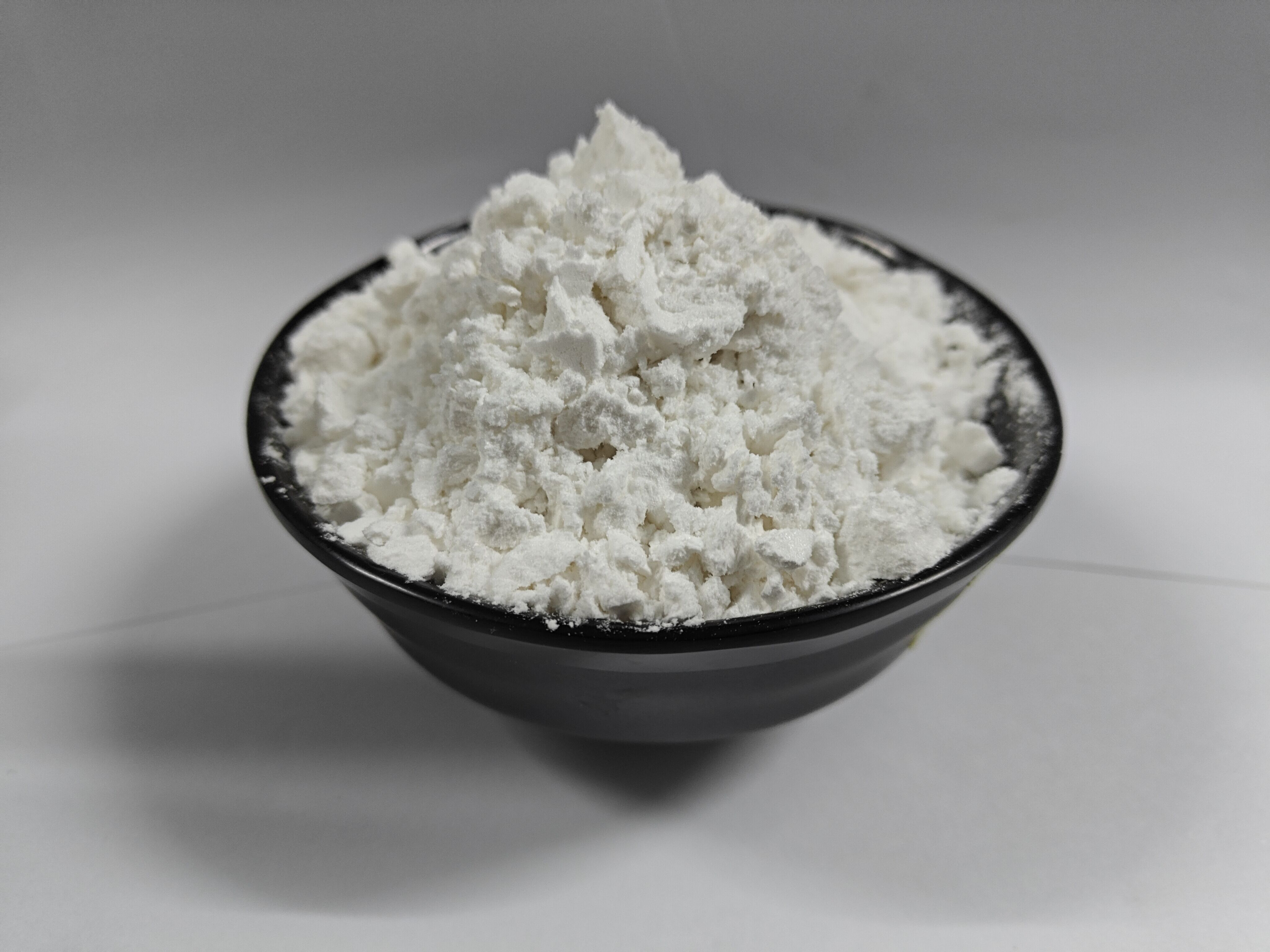

N,N'-Carbonyldiimidazool (CDI) is 'n veelsydige chemiese reagens wat wydverspreid in organiese sintese en farmasieutiese vervaardiging gebruik word. Hierdie wit kristallinse samestelling dien as 'n doeltreffende koppelingsagente vir die vorming van amide, esters en ander karbonyl-bevatte samestellings. CDI funksioneer deur karboksylsuure te aktiveer deur die vorming van reaktiewe intermediates, wat volgende reaksies met nukleofile moontlik maak. In farmasieutiese toepassings speel dit 'n sleutelrol in peptiedsintese en die vervaardiging van verskeie geneesmiddel-intermediate. Die samestelling wys uitstekende selektiwiteit en produseer imidazool as 'n byprodukt, wat maklik uit reaksiemengsels verwyder kan word. Sy stabiliteit onder normale stoorvoorwaardes en kompatibiliteit met verskeie oplossers maak dit spesiaal waardevol in industriële prosesse. CDI se werkingsmechanisme behels die vorming van 'n aktiveerde akyl-imidazool-intermediate, wat dan met verskeie nukleofile kan reageer om die gewenste produkte te vorm. Hierdie kenmerk maak dit 'n onmisbare hulpmiddel in sowel navorsingslaboratoriums as in industriële omgewings, veral in die ontwikkeling van nuwe farmasieutiese samestellings en fynchemikalië.