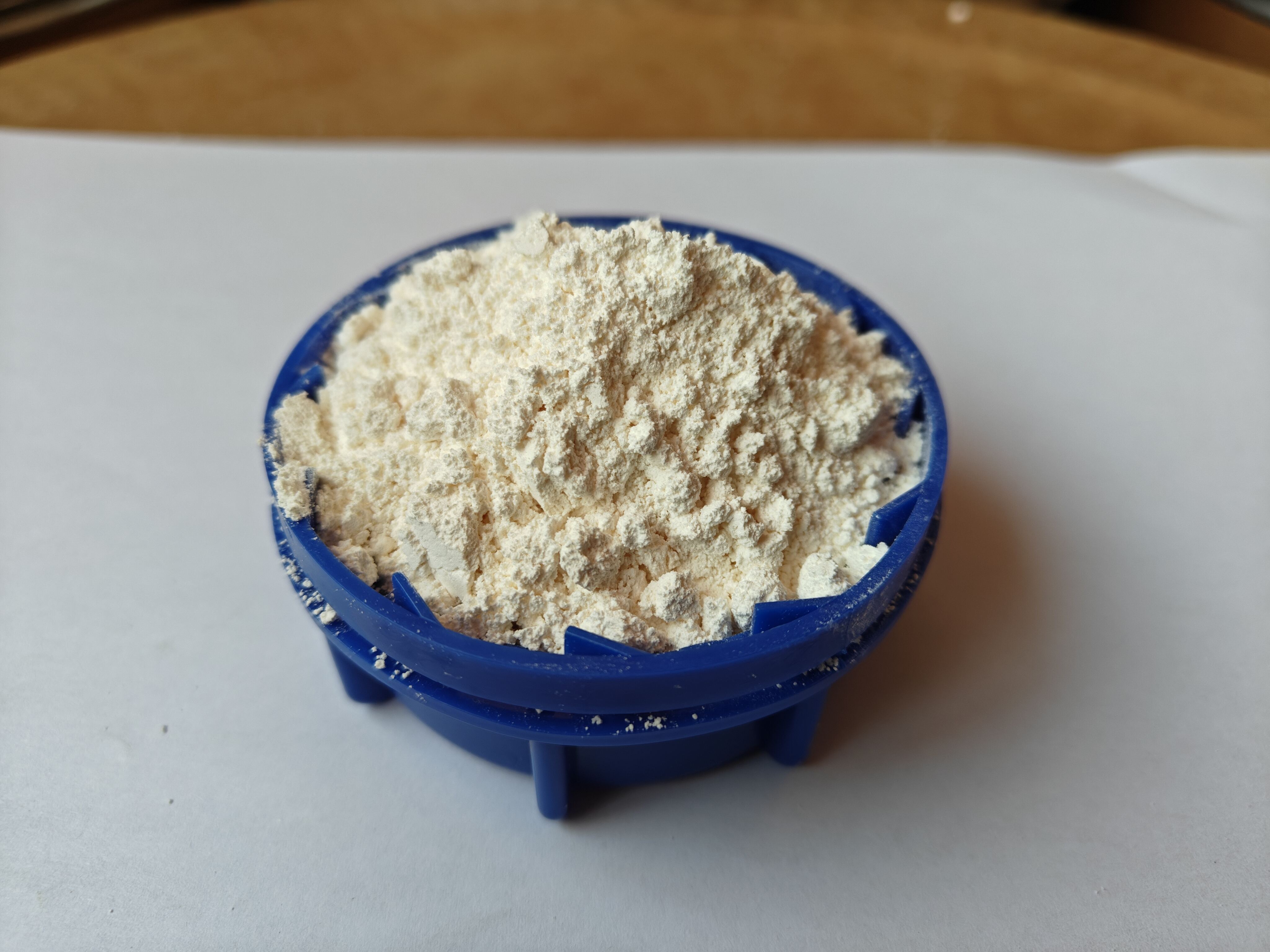

imidazoolring vir verhardingsversnelling

Die imidazoolring staan as 'n kruisbestanddeel in moderne geneesversnellingstegnologie, wat 'n beduidende vooruitgang in chemiese verwerking en materiaalwetenskappe verteenwoordig. Hierdie heterosikliese samestelling, gekenmerk deur sy vyf-lidringestruktur wat twee stikstofatome bevat, dien as 'n kragtige katalisator in verskeie geneesprosesse. Die unieke molekulêre struktuur van die imidazoolring laat dit toe om doeltreffend die polimerisasieringreaksies, veral in epokssisteme, te begin en te versnel. Sy primêre funksies sluit in die verlaging van geneestemperatuurs, verkorting van geneetyd en verbetering van die algehele doeltreffendheid van die geneesproses. Die tegnologie het 'n opmerkbare vermoë om stabiliteit by ruimtetemperatuur te handhaaf terwyl dit hoë reaksiekrag toon wanneer dit by spesifieke temperatuurs aktief word. Hierdie kenmerk maak dit veral waardevol in toepassings wat presiese beheer oor die begin en voortgang van die genees vereis. In industriële toepassings wys die imidazoolring uitsonderlike veelsydigheid deur in elektroniese komponente, samestellingsmateriale, lijmstoffe en bedekkingstelsels gebruik te word. Die samestelling se vermoë om uniforme genees te bevorder en by te dra tot verbeterde eindprodukken eienskappe het dit onontbeerlik gemaak in moderne vervaardigingsprosesse.