china termies latente katalisators

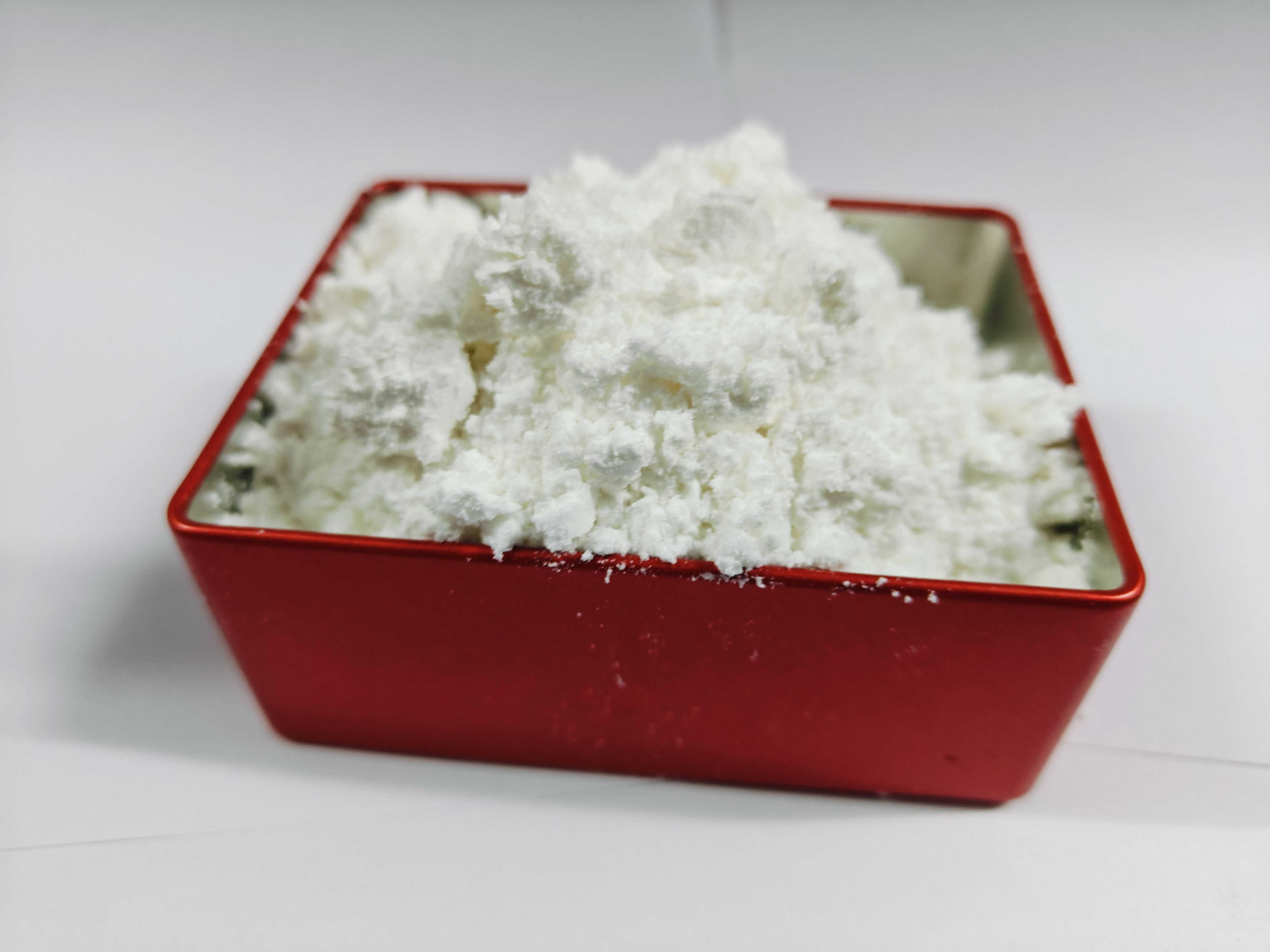

China termieslatente katalisators verteenwoordig 'n baanbrekende vooruitgang in chemiese reaksie-tegnologie, wat presiese beheer bied oor reaksietyd en temperatuur-afhanklike aktivering. Hierdie sofistikeerde katalisators bly dormaan by ruimtetemperatuur maar word hoog aktief wanneer hulle blootgestel word aan spesifieke temperatuurgrense, wat gewoonlik tussen 80°C en 200°C reik. Hierdie unieke kenmerk stel een in staat om meer beheer te hê oor polimerisasieprosesse, kuringsreaksies en verskeie industriële toepassings. Die katalisators bestaan uit spesiaal ontwerpde molekulêre strukture wat konformasie-veranderinge ondergaan by verhoogde temperature, wat hul aktiewe plekke blootstel en die gewenste chemiese reaksies initieer. Hul implementering het vervaardigingsprosesse gerevolutioneer, veral in die elektronika-, motorbedekkinge- en lijm-industrieë. Die tegnologie sluit gevorderde koördinasie-kemie-prinsipes in, wat metale komplekse en organiese ligande gebruik wat voorspelbaar op termiese stimulasie reageer. Hierdie beheerde aktiveringsmekanismus voorkom vroegtydige reaksies, verleng potlewe en verseker optimale prosesse-condities. Die katalisators wys uitstekende stabiliteit tydens berging en vervoer, wat hulle ideaal maak vir kommersiële toepassings wat presiese reaksietyd en beheerde prosesse-condities vereis.